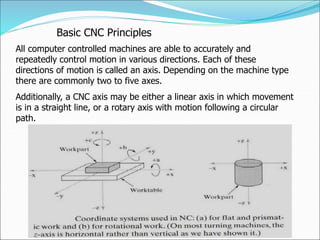

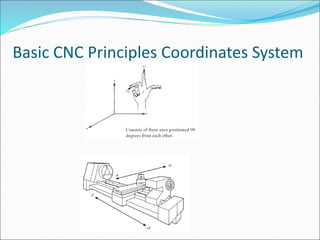

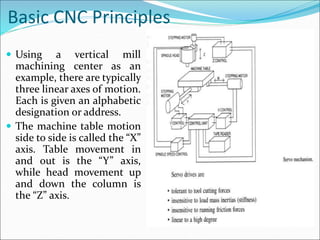

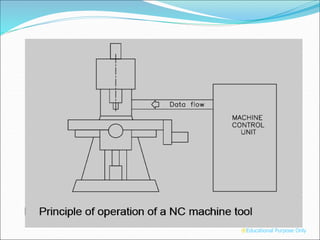

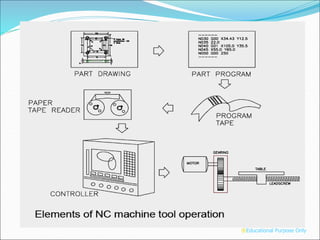

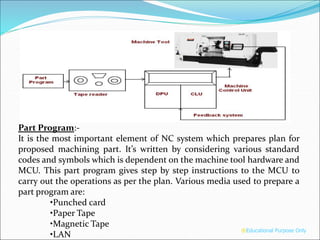

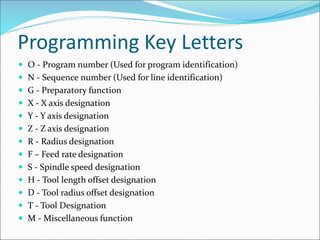

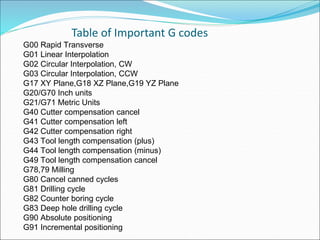

Numerical control (NC) uses letters, numbers and symbols to automate machine tool functions like spindle speed, tool positioning, and feed rate (paragraph 1). NC allows automatic control of starting/stopping the spindle, spindle speed, tool positioning along paths, feed rate, and tool changes (paragraph 2). Common NC machine tools have automated control over functions like the X, Y, and Z axes of a milling machine (paragraph 3).