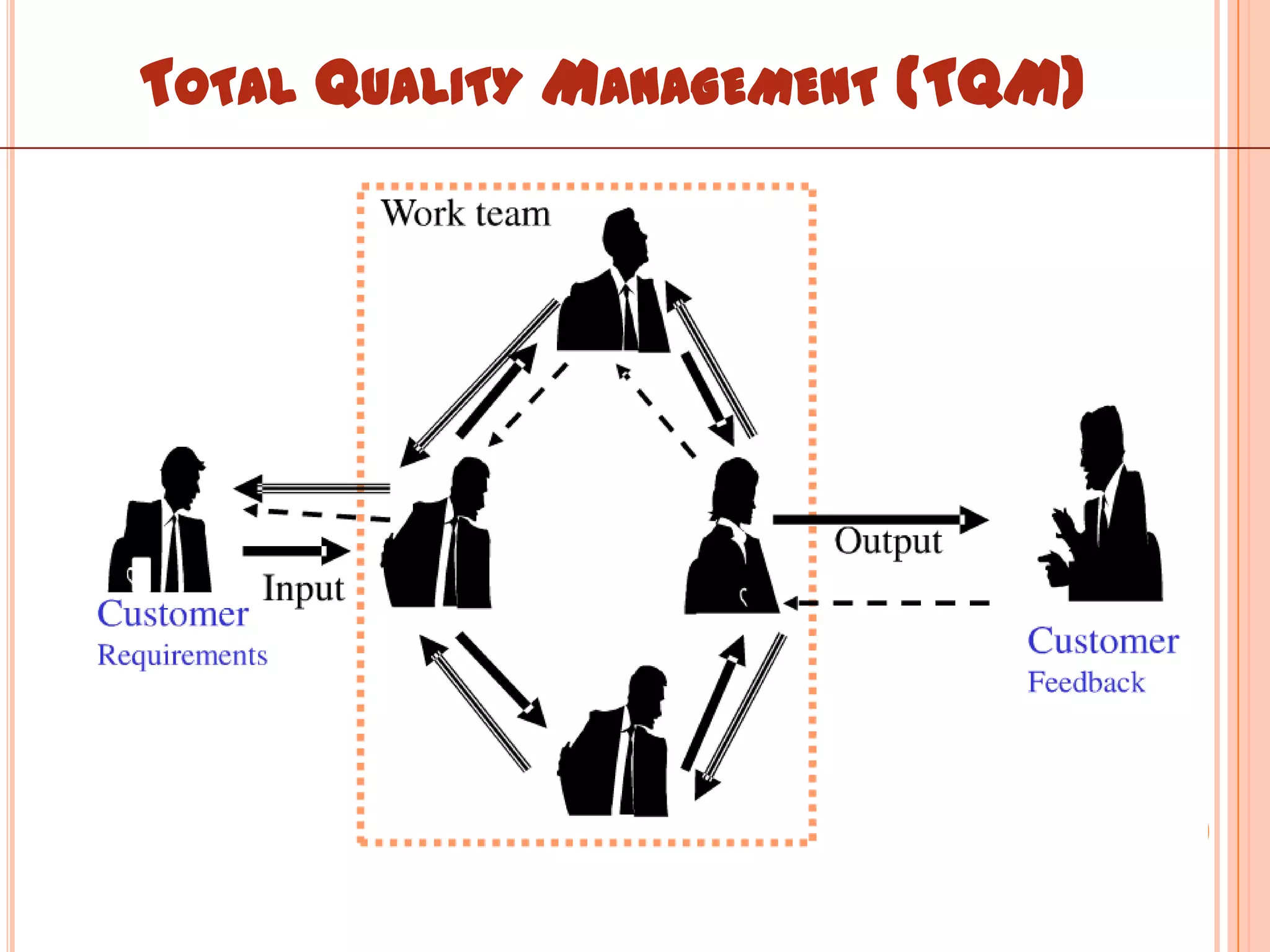

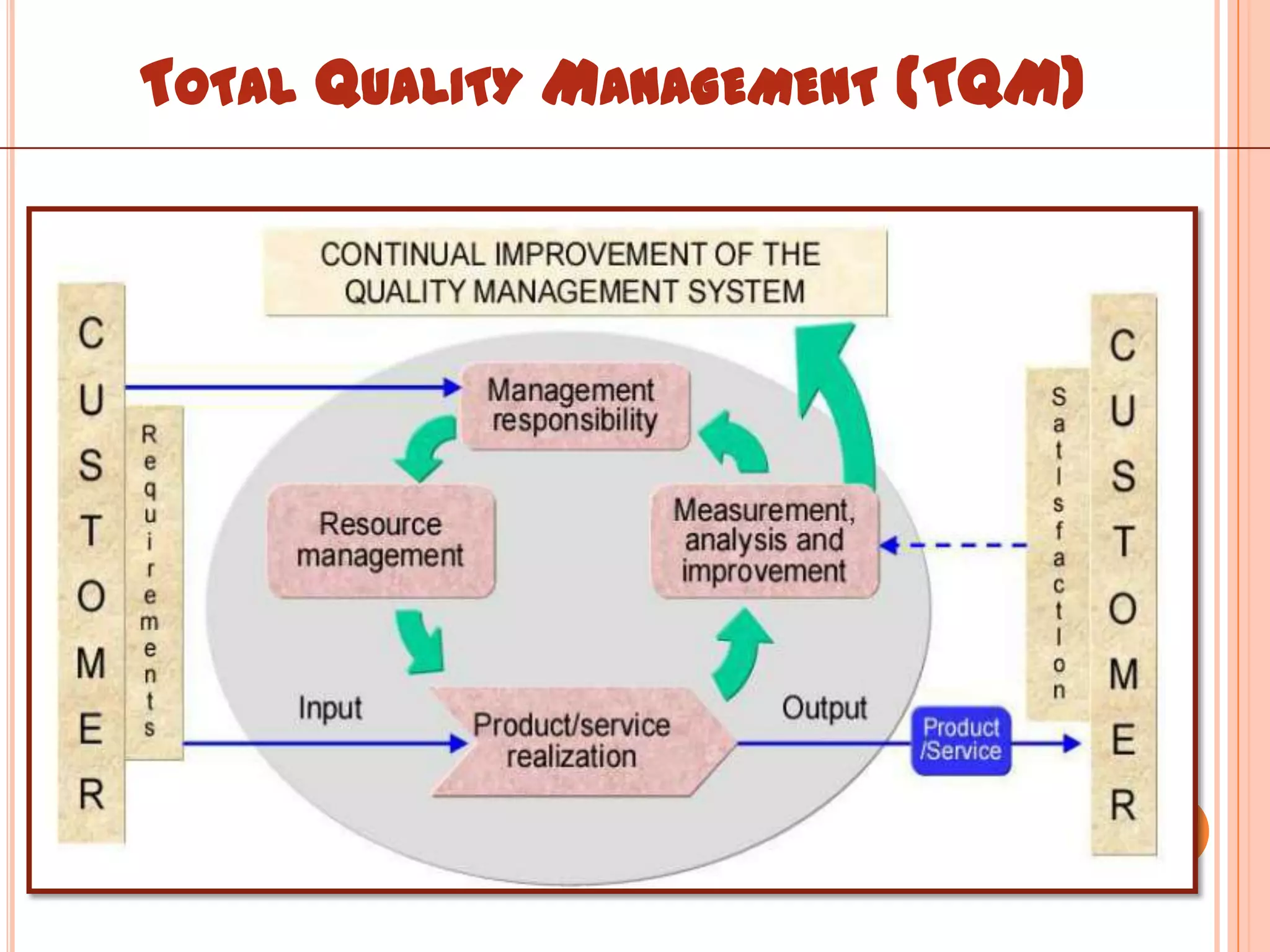

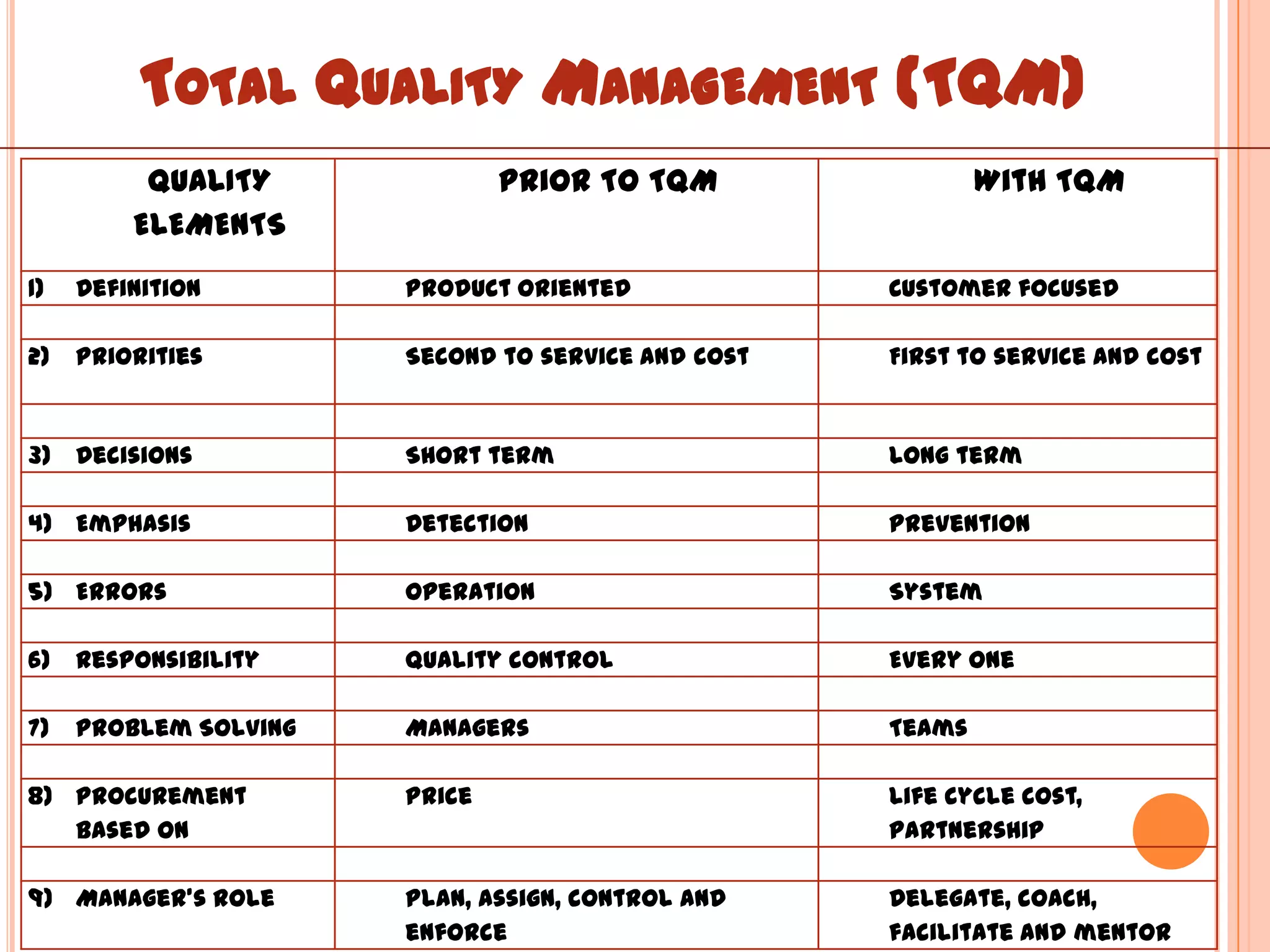

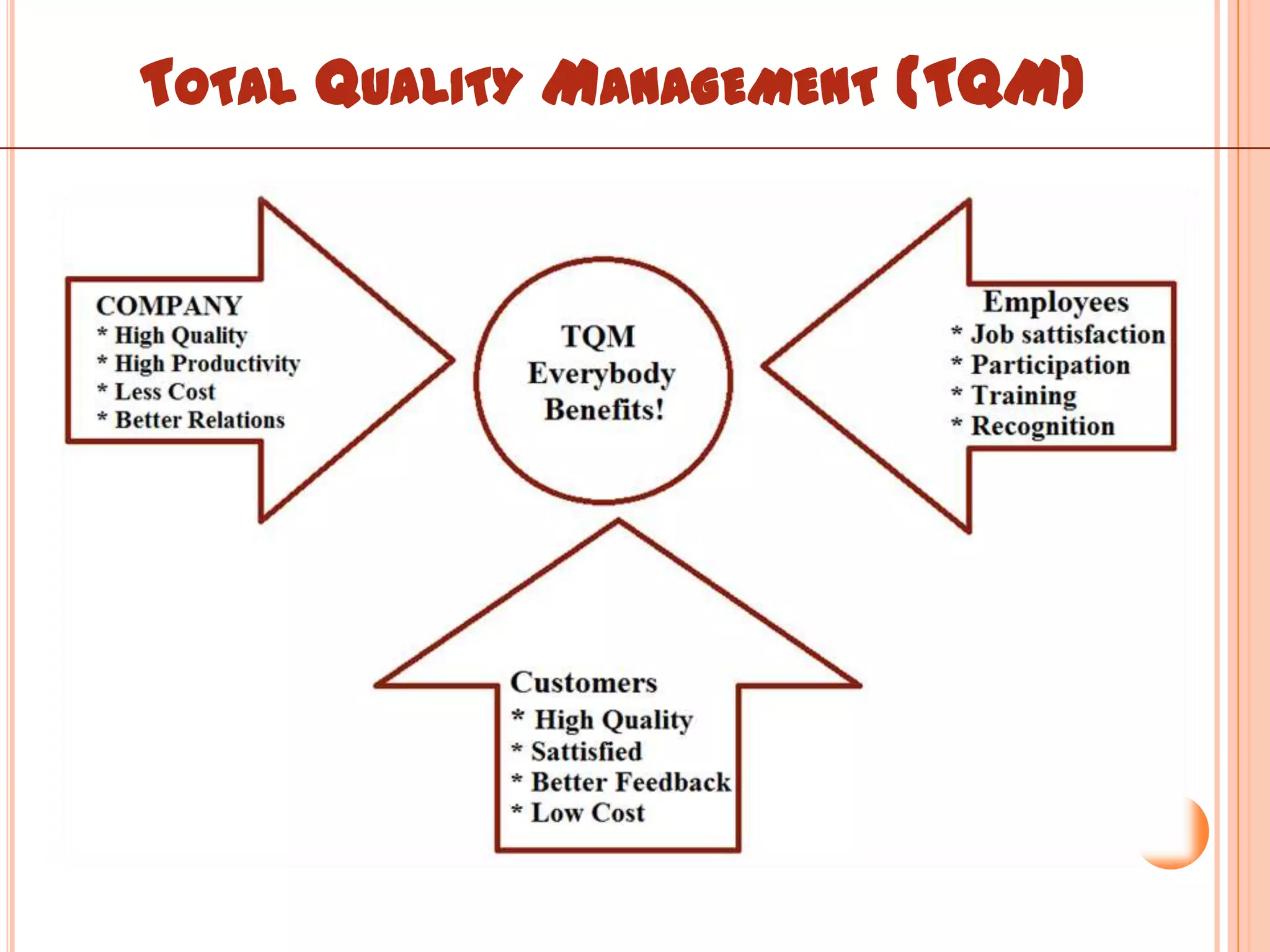

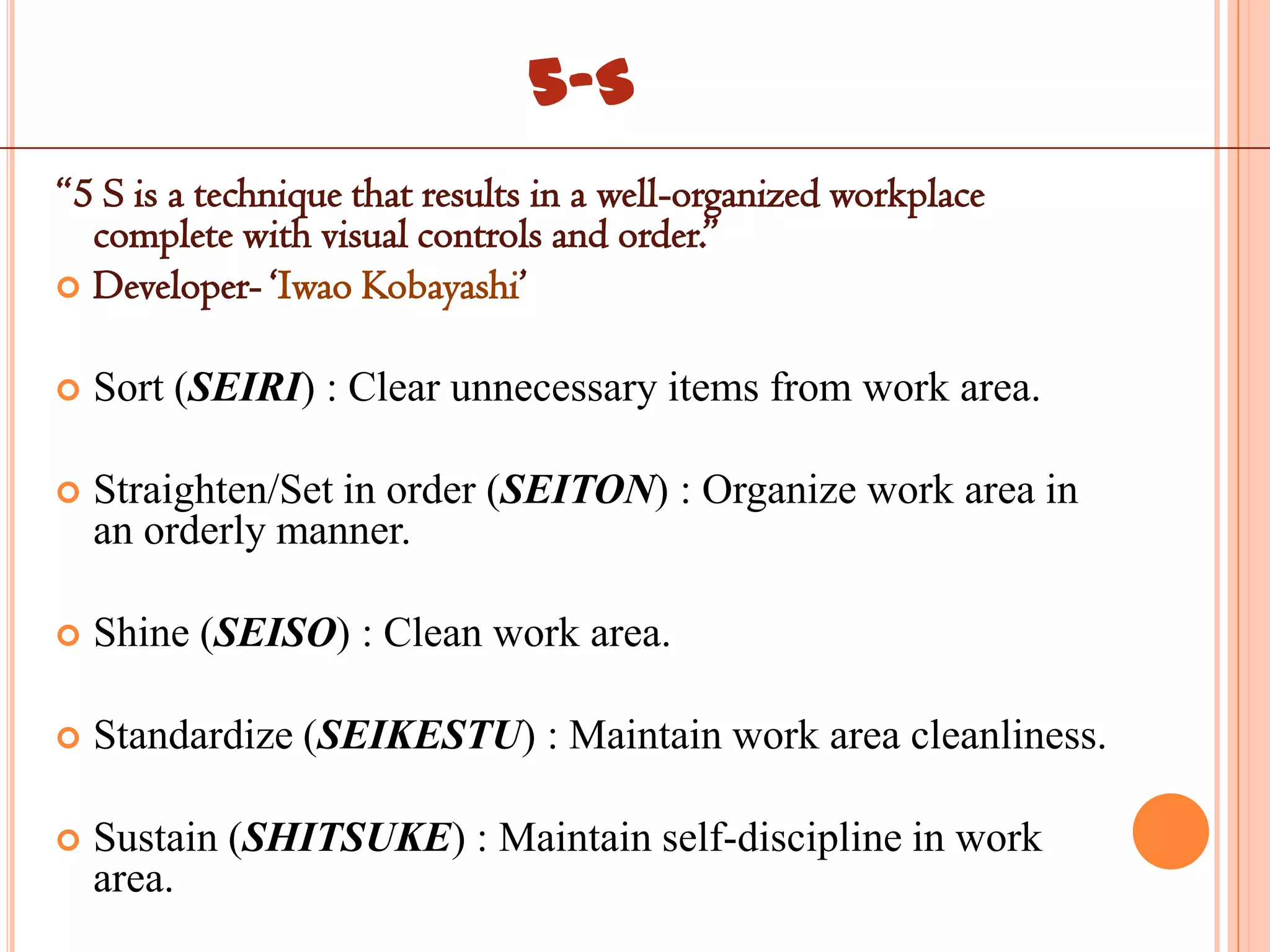

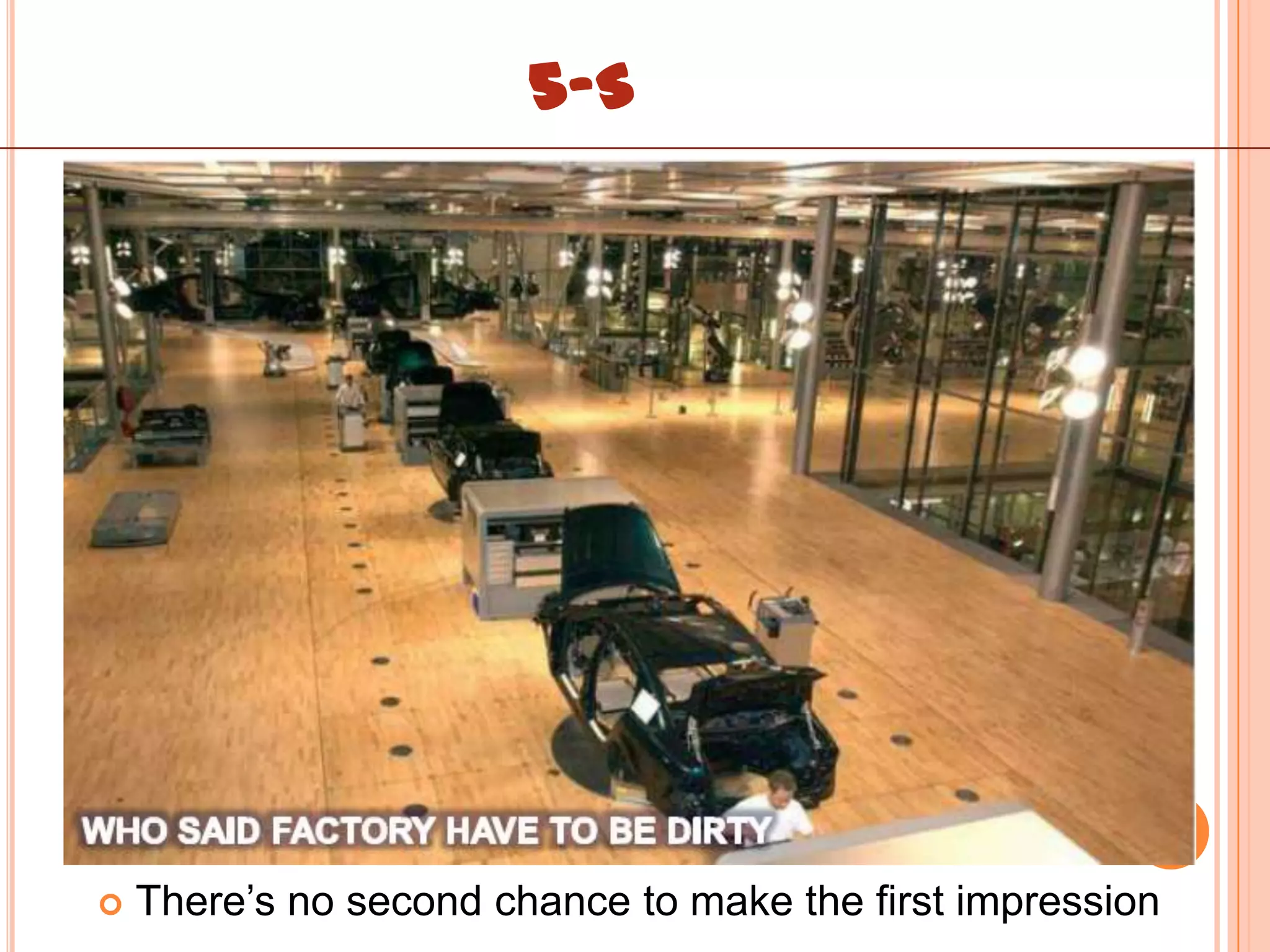

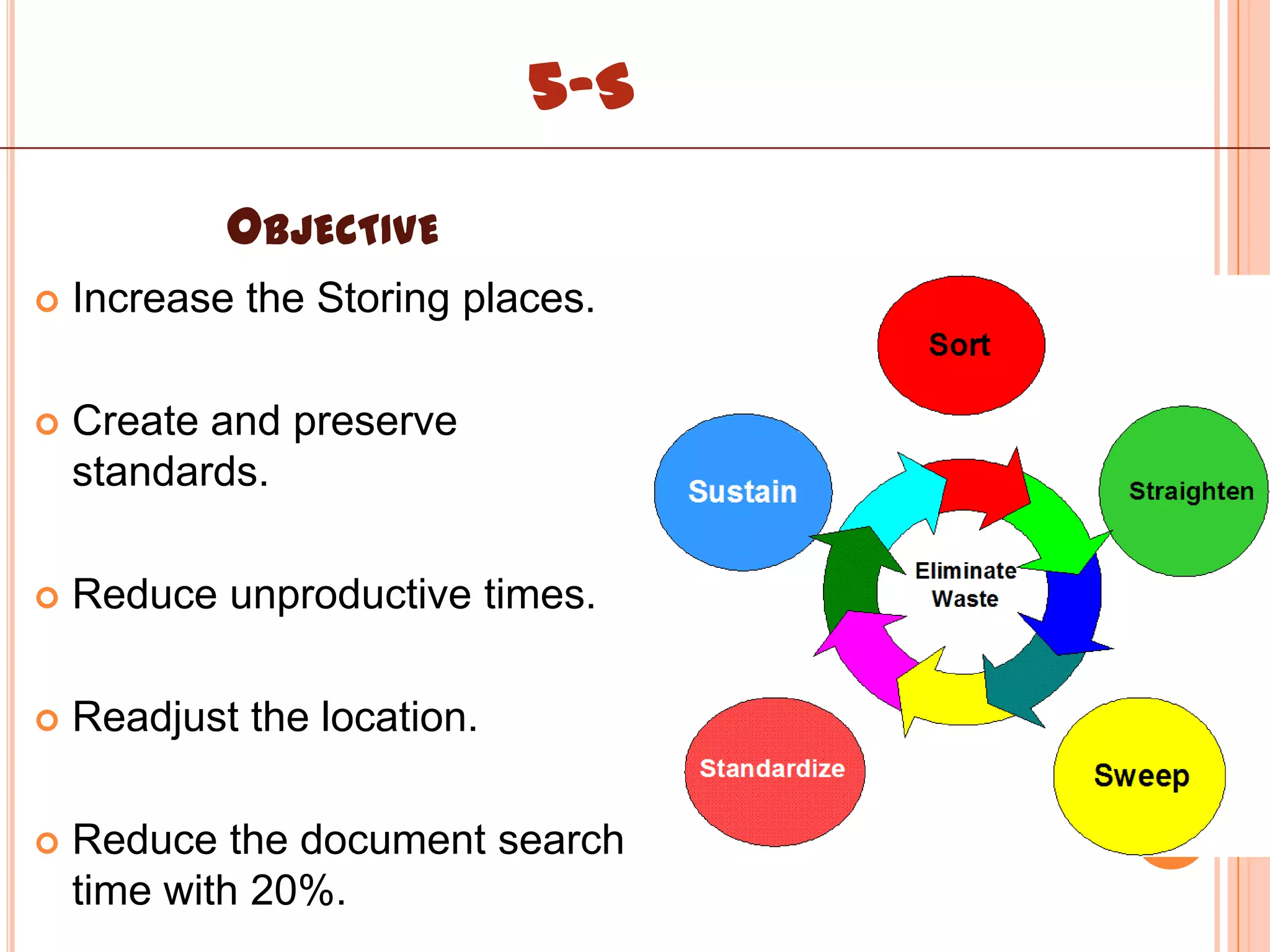

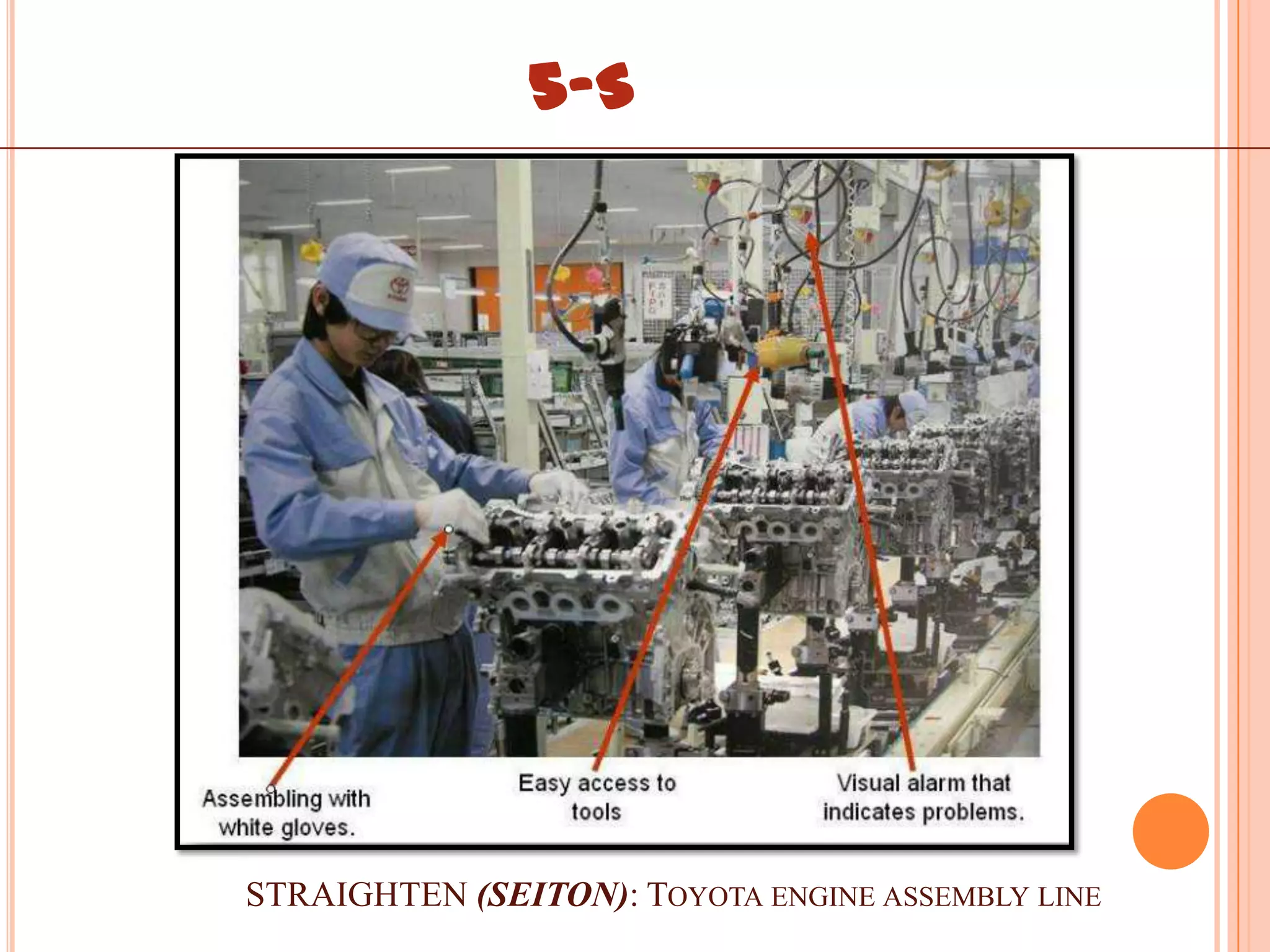

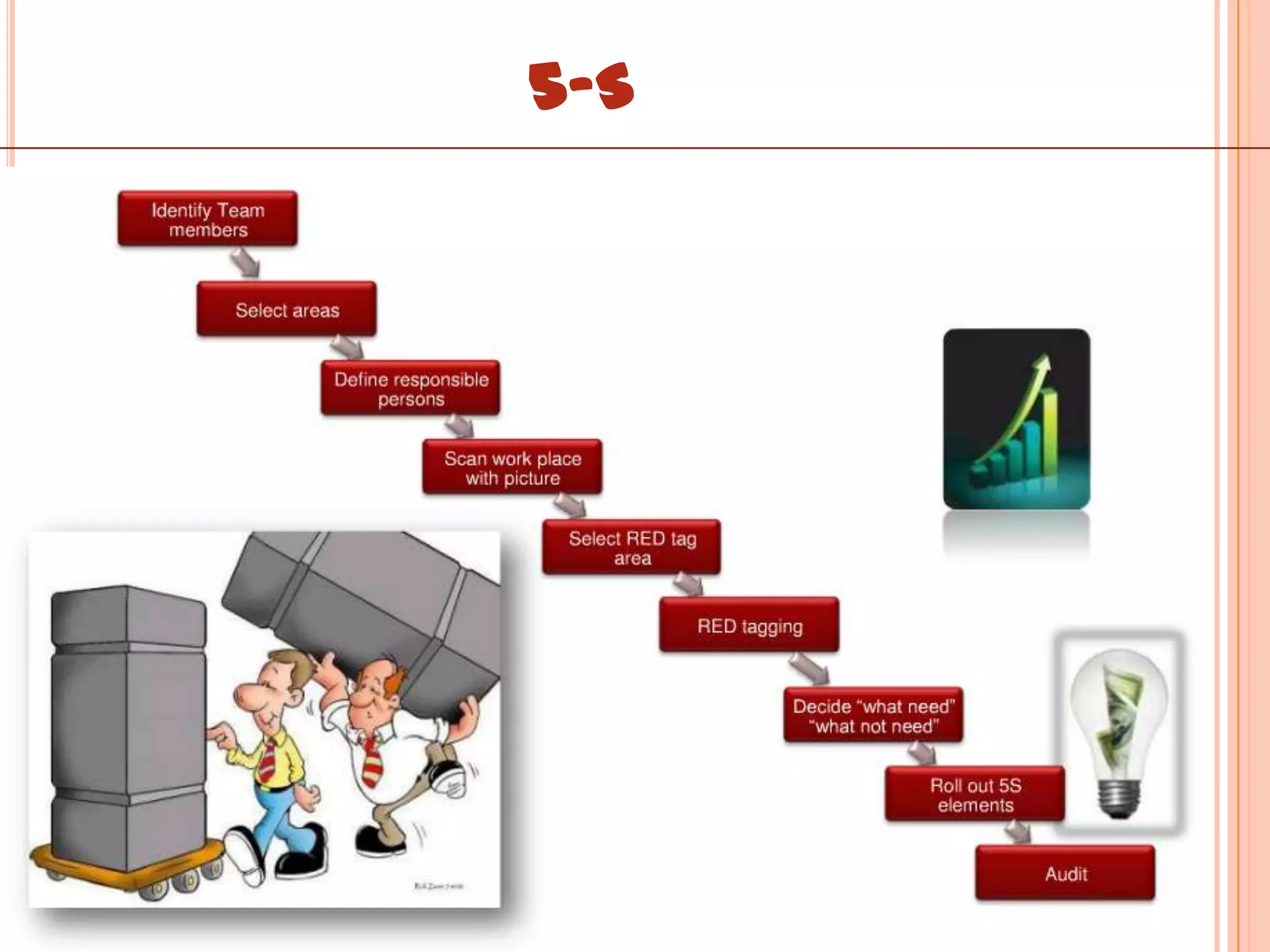

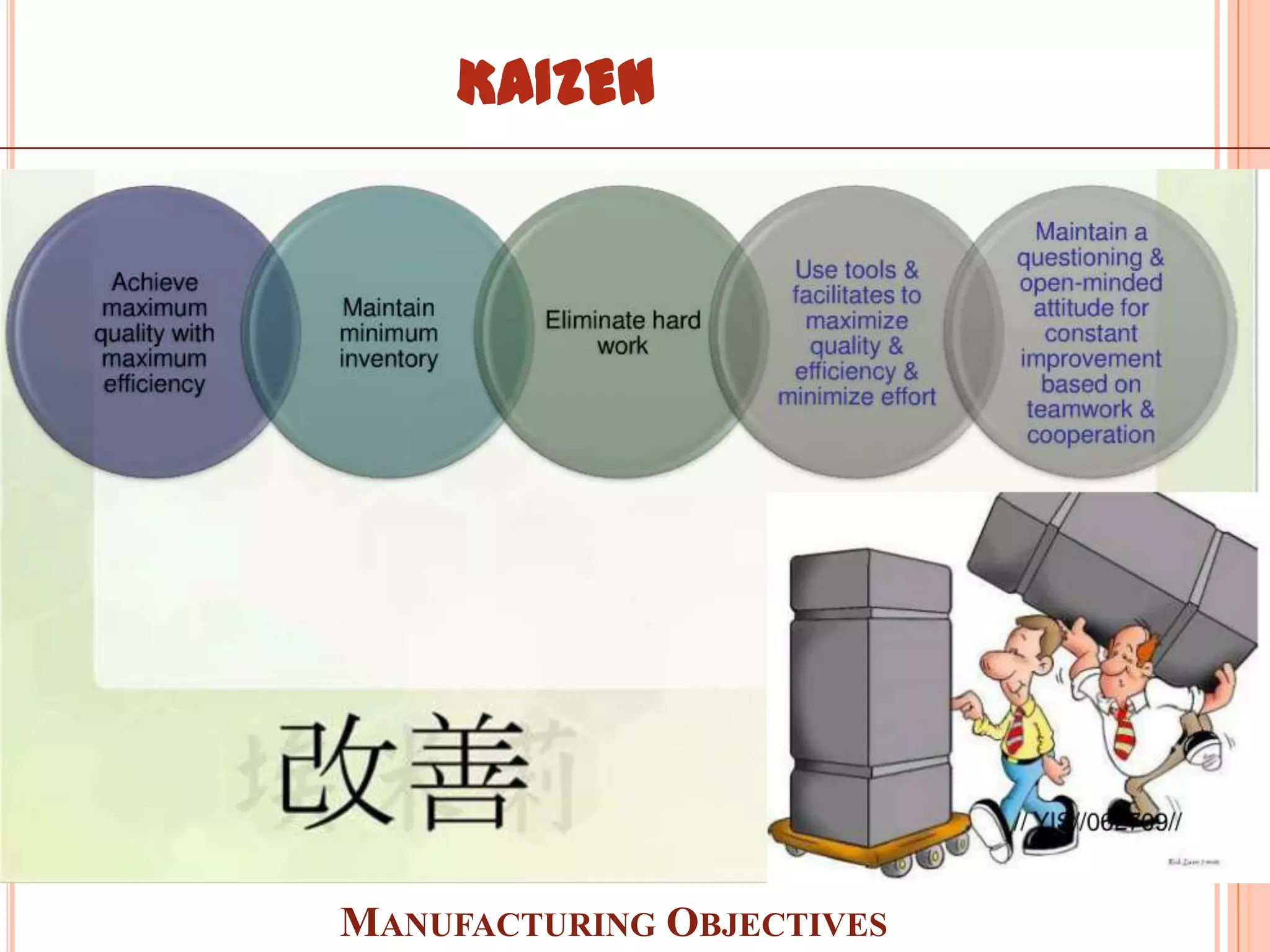

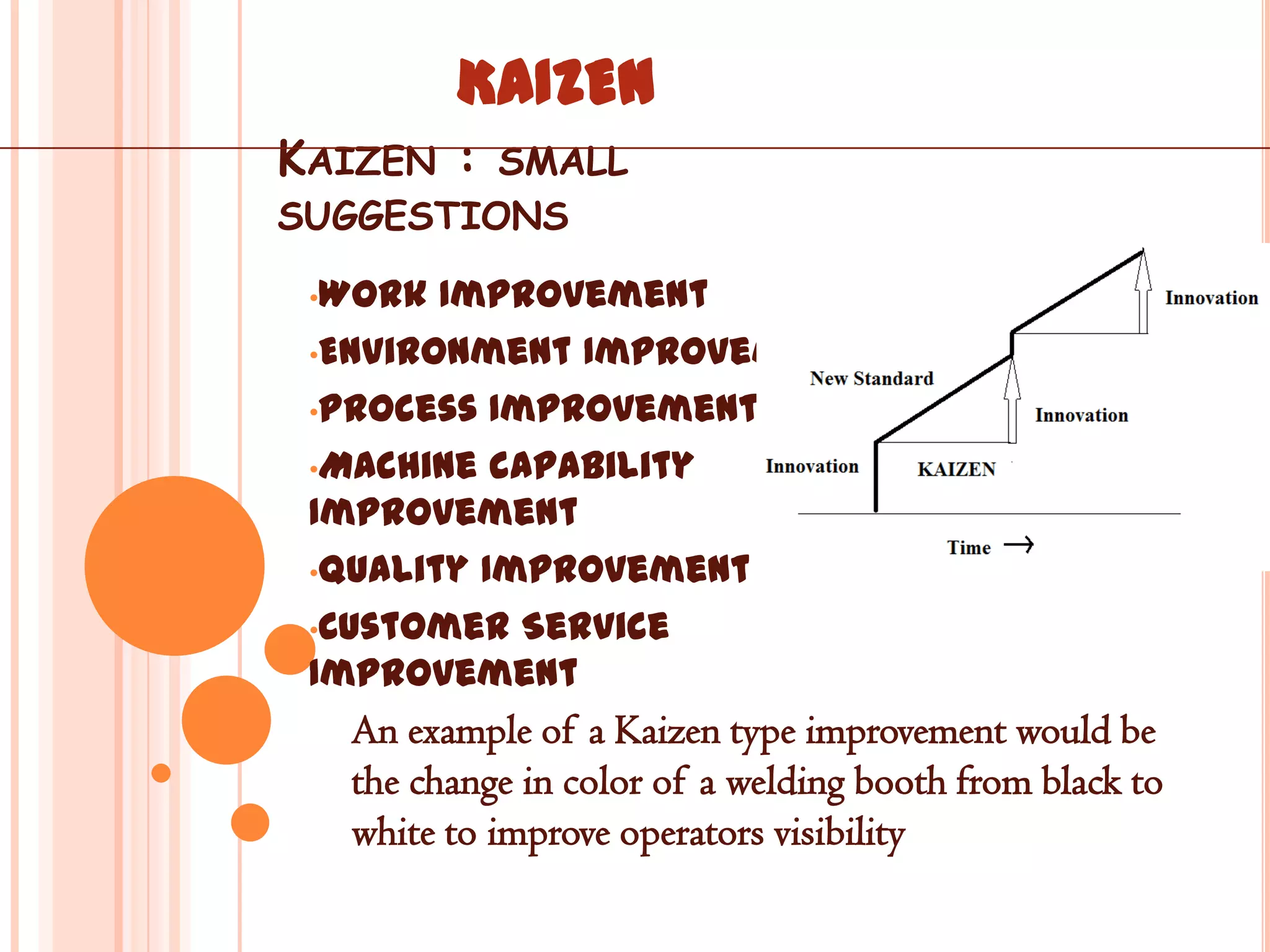

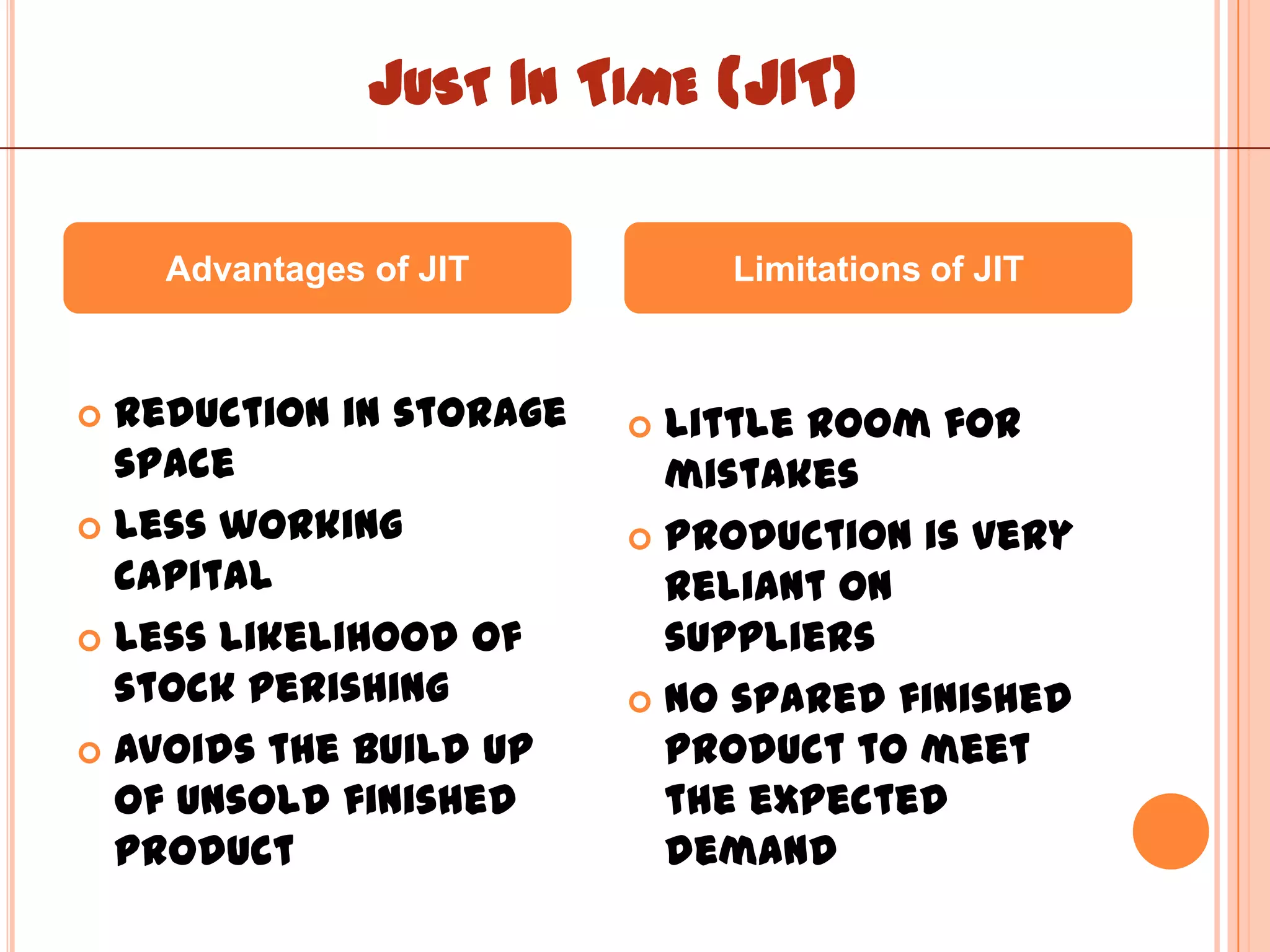

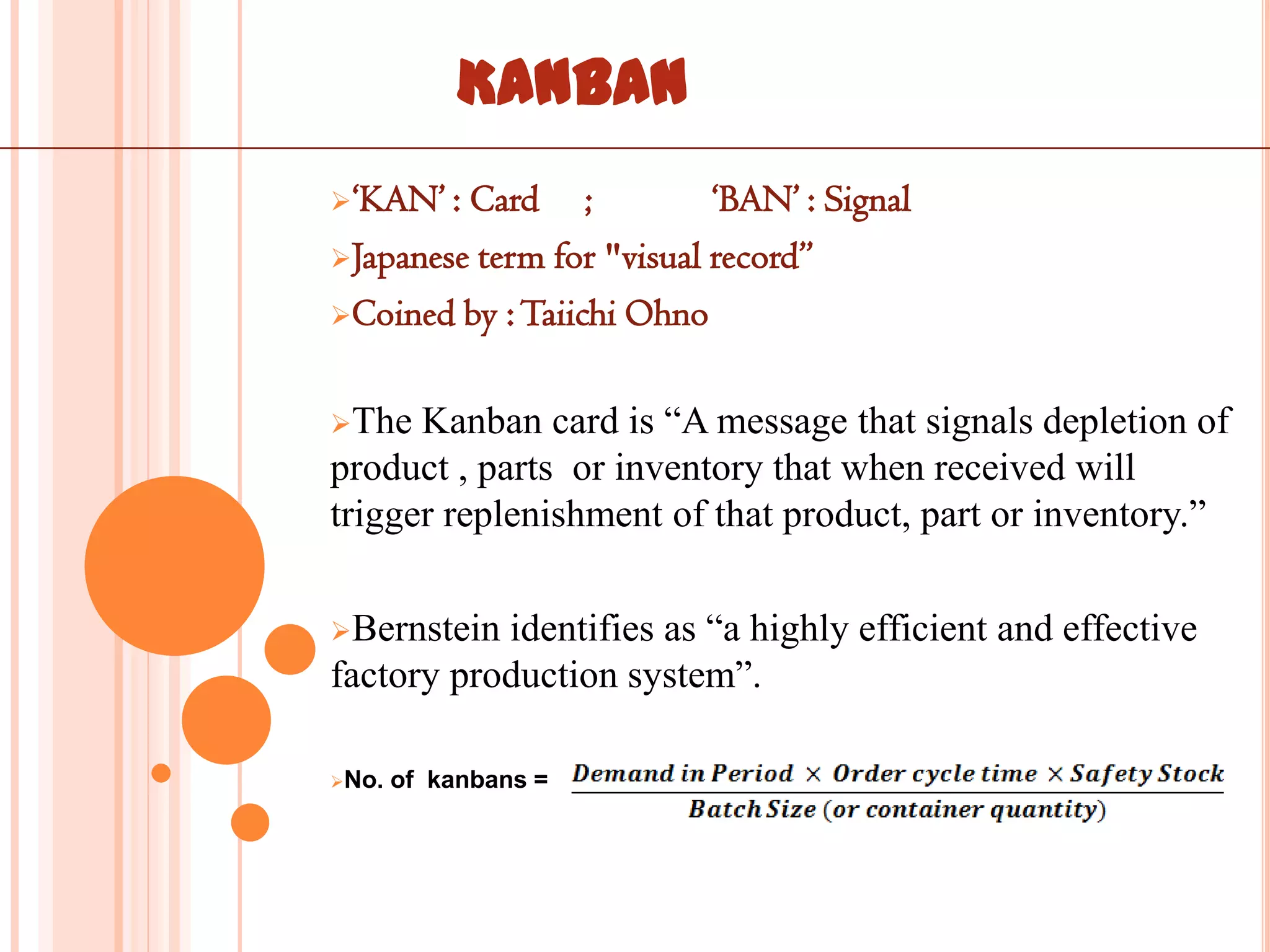

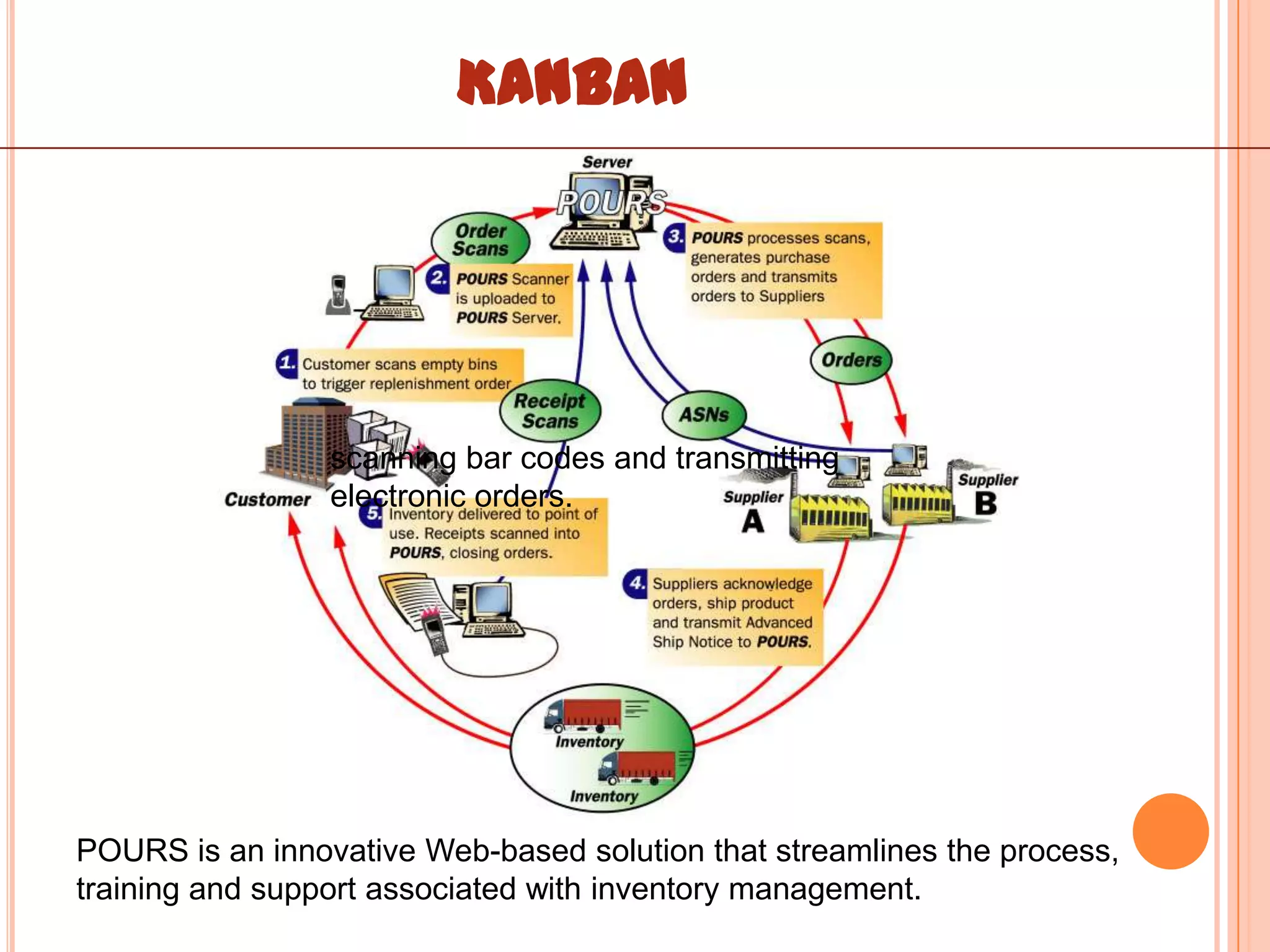

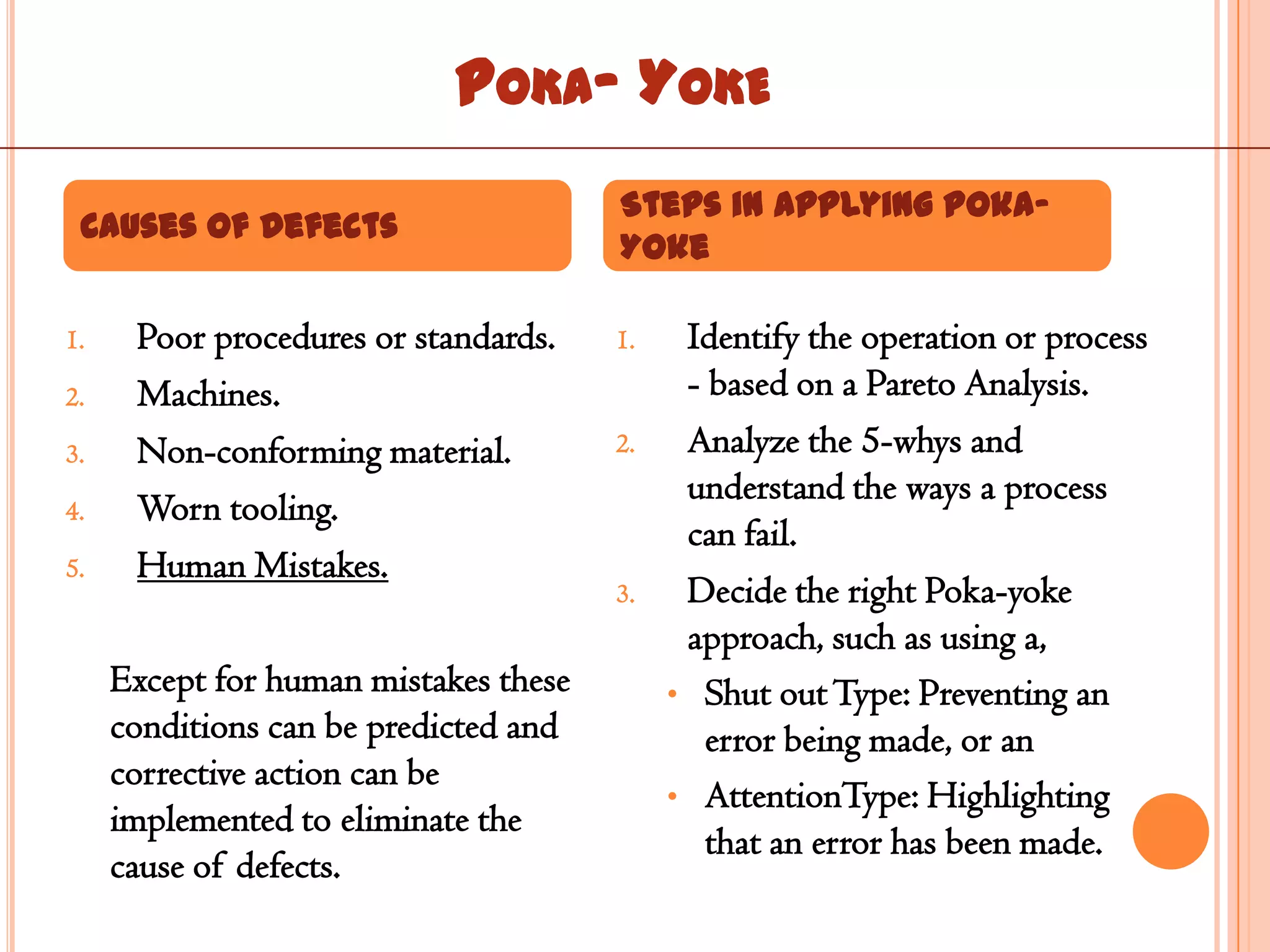

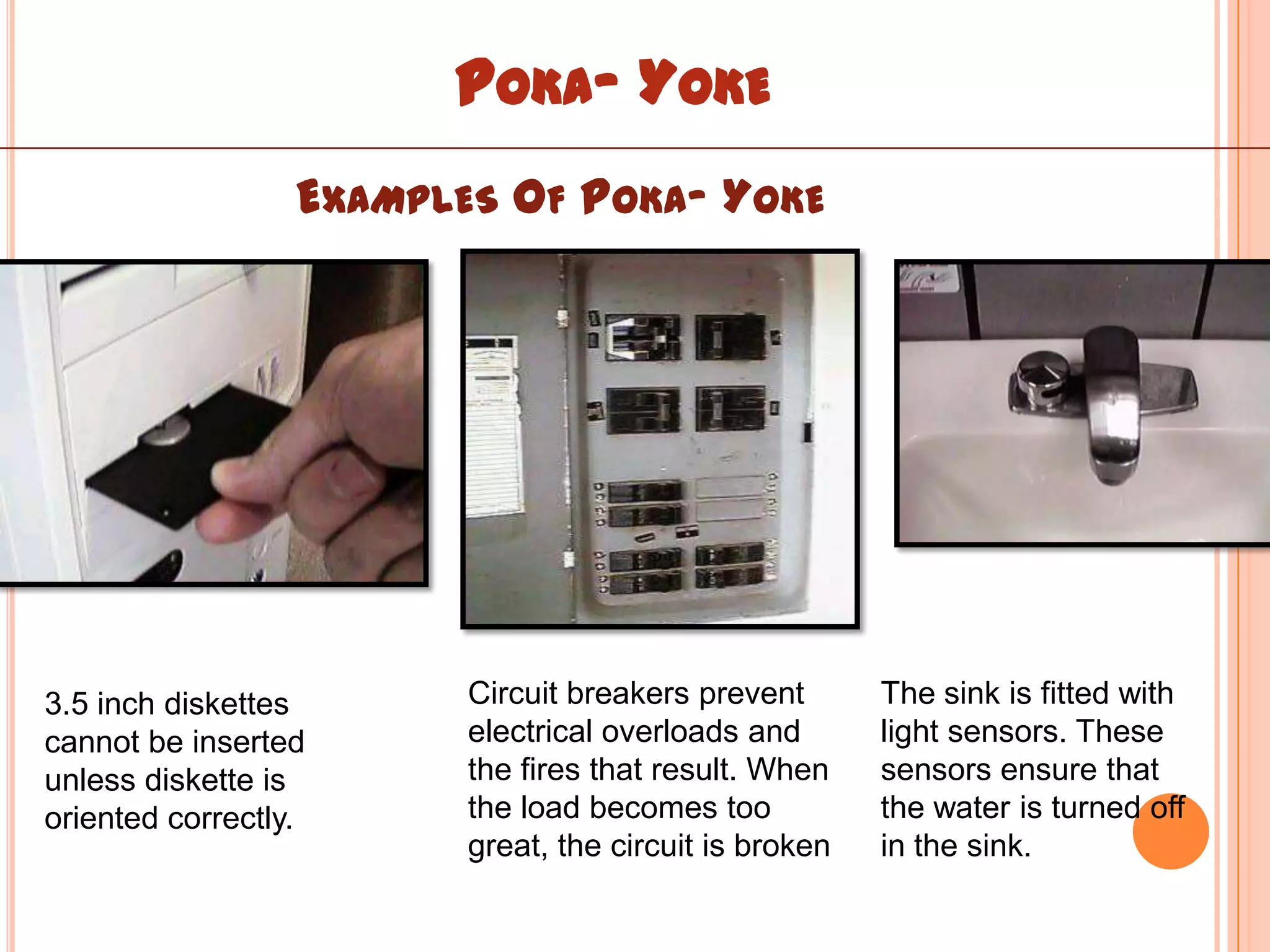

The document provides an overview of quality management techniques including Total Quality Management (TQM), 5S, Kaizen, Just-in-Time (JIT), Kanban, and Poka-Yoke. It defines each technique and discusses their objectives, key aspects, benefits, and examples. TQM focuses on customer satisfaction through a philosophy of continuous improvement involving all departments. 5S creates organization and standardization in the workplace. Kaizen emphasizes continuous small improvements through teamwork. JIT and Kanban together form a pull-based production system to reduce waste. Poka-Yoke aims to prevent mistakes through automatic error-proofing mechanisms.