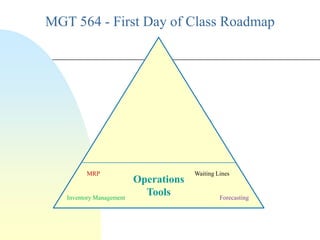

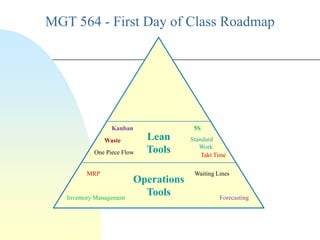

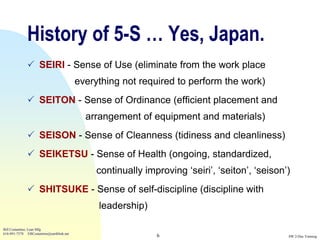

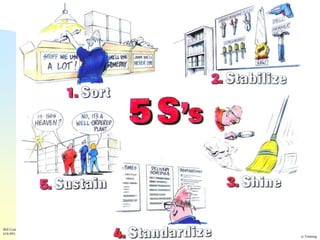

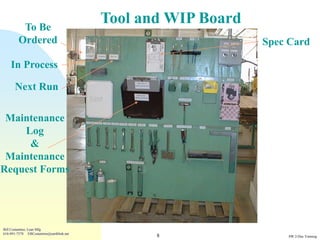

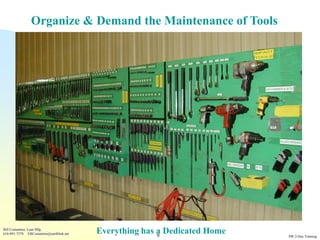

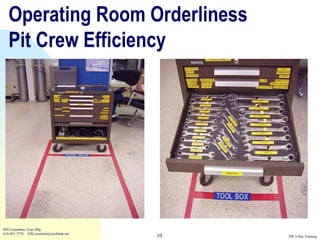

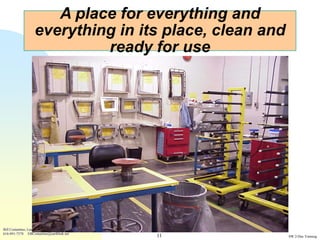

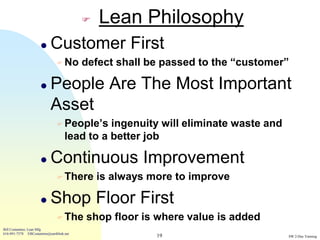

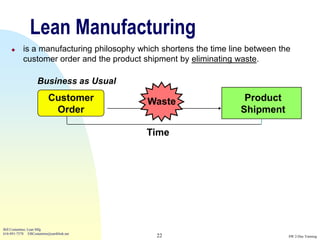

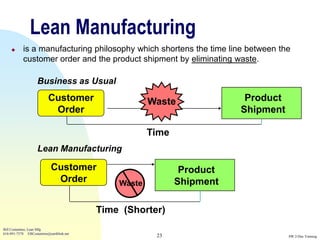

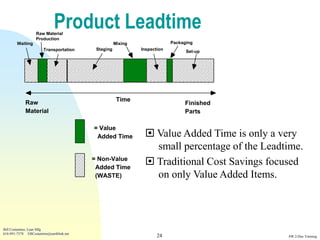

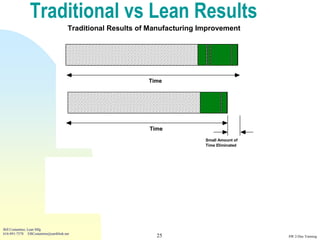

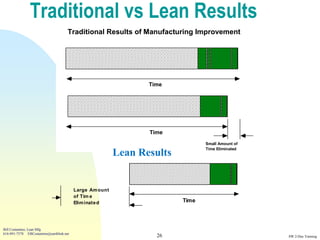

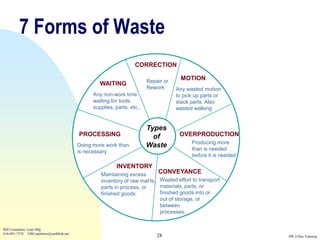

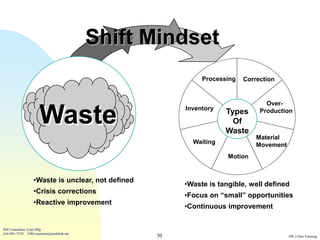

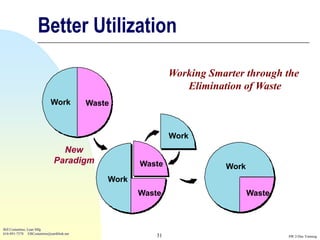

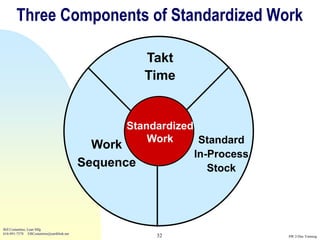

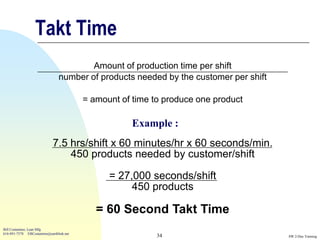

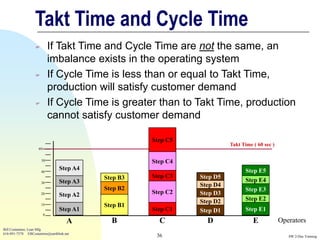

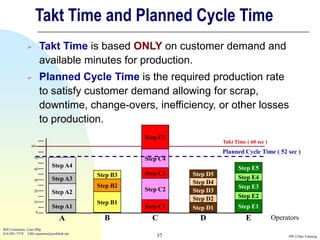

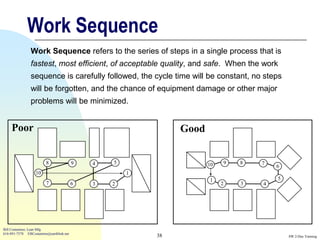

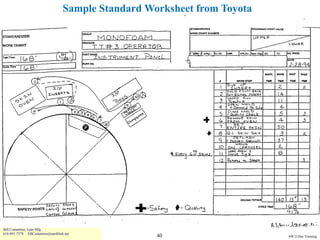

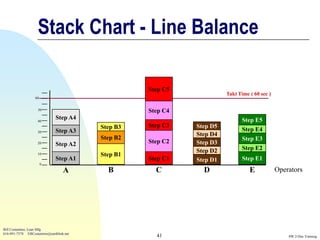

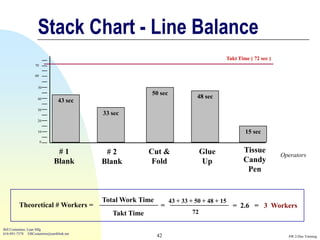

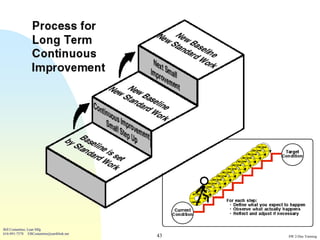

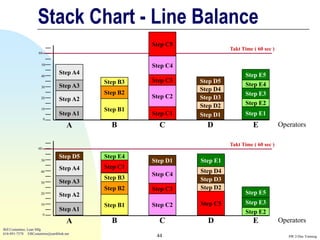

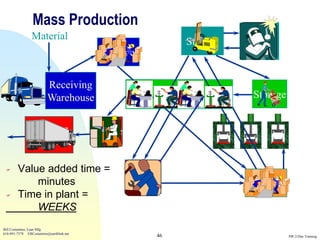

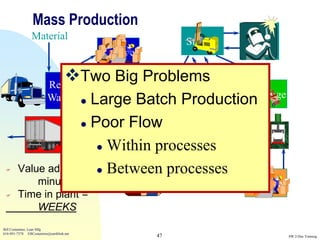

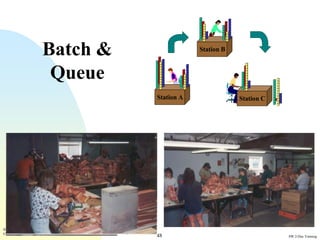

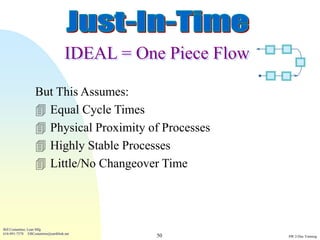

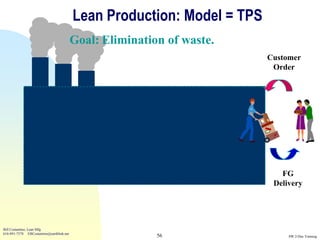

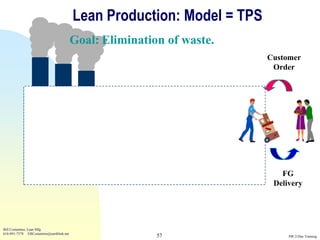

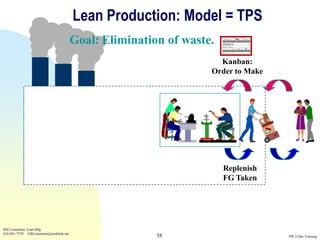

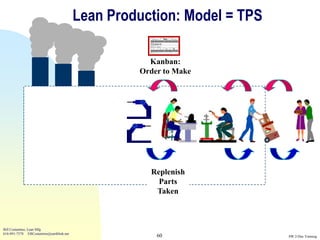

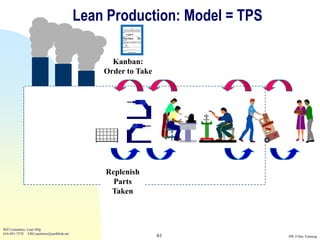

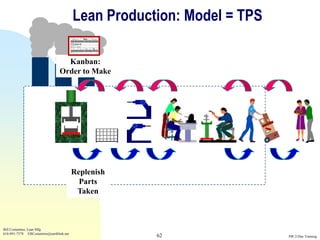

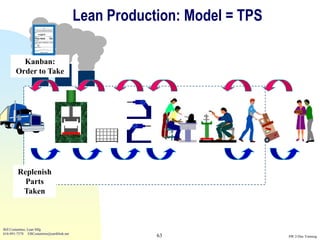

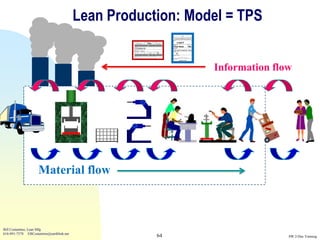

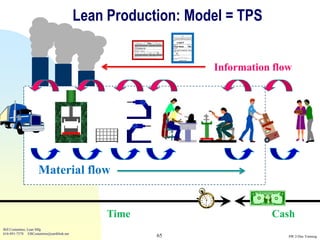

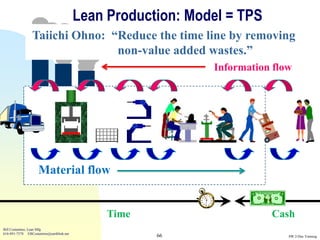

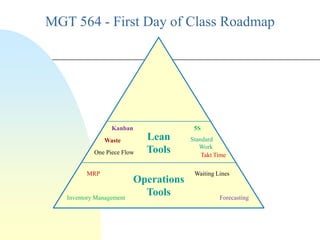

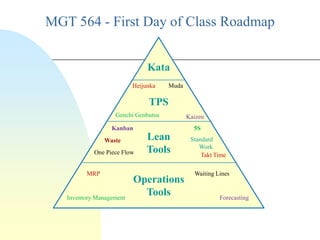

The document discusses the Toyota Production System and various lean manufacturing tools aimed at improving operational efficiency by eliminating waste. It outlines key concepts such as 5S (sort, set in order, shine, standardize, sustain), takt time, standardized work, and visual controls to enhance production flow and reduce lead times. The ultimate goal highlighted is to deliver customer value while minimizing resource use and maximizing productivity.