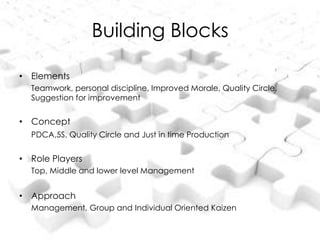

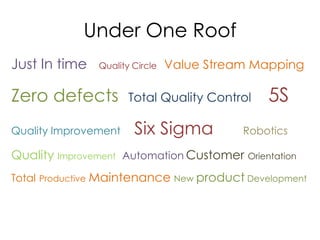

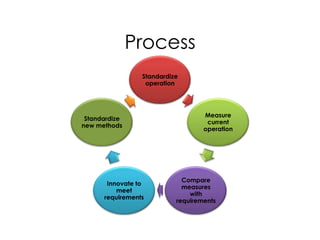

Kaizen is a Japanese philosophy of continuous improvement. [1] It was developed after World War II based on American management concepts and first applied by Toyota. [2] Kaizen focuses on eliminating waste through small, incremental changes using a plan-do-check-act cycle and techniques like 5S, quality circles, and just-in-time production. [3] The goals are to standardize operations, measure performance against requirements, and continuously innovate to improve quality, efficiency and morale. [3] Kaizen principles can be applied in any environment to drive measurable results through teamwork and an emphasis on eliminating outdated assumptions.