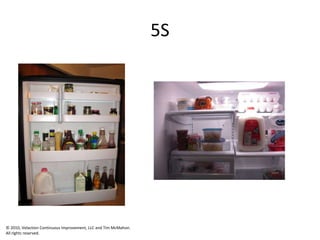

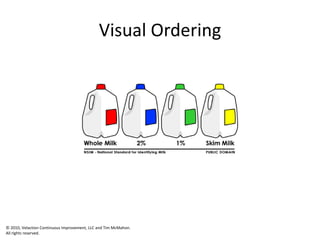

The document is a presentation titled 'Learning Lean from Home' by Jeff Hajek and Tim McMahon, focusing on lean principles and practices. It includes information on 5S methodology, kanban systems, and an upcoming show on lean applications in automobiles. The presentation can be modified and distributed within an organization but not externally.