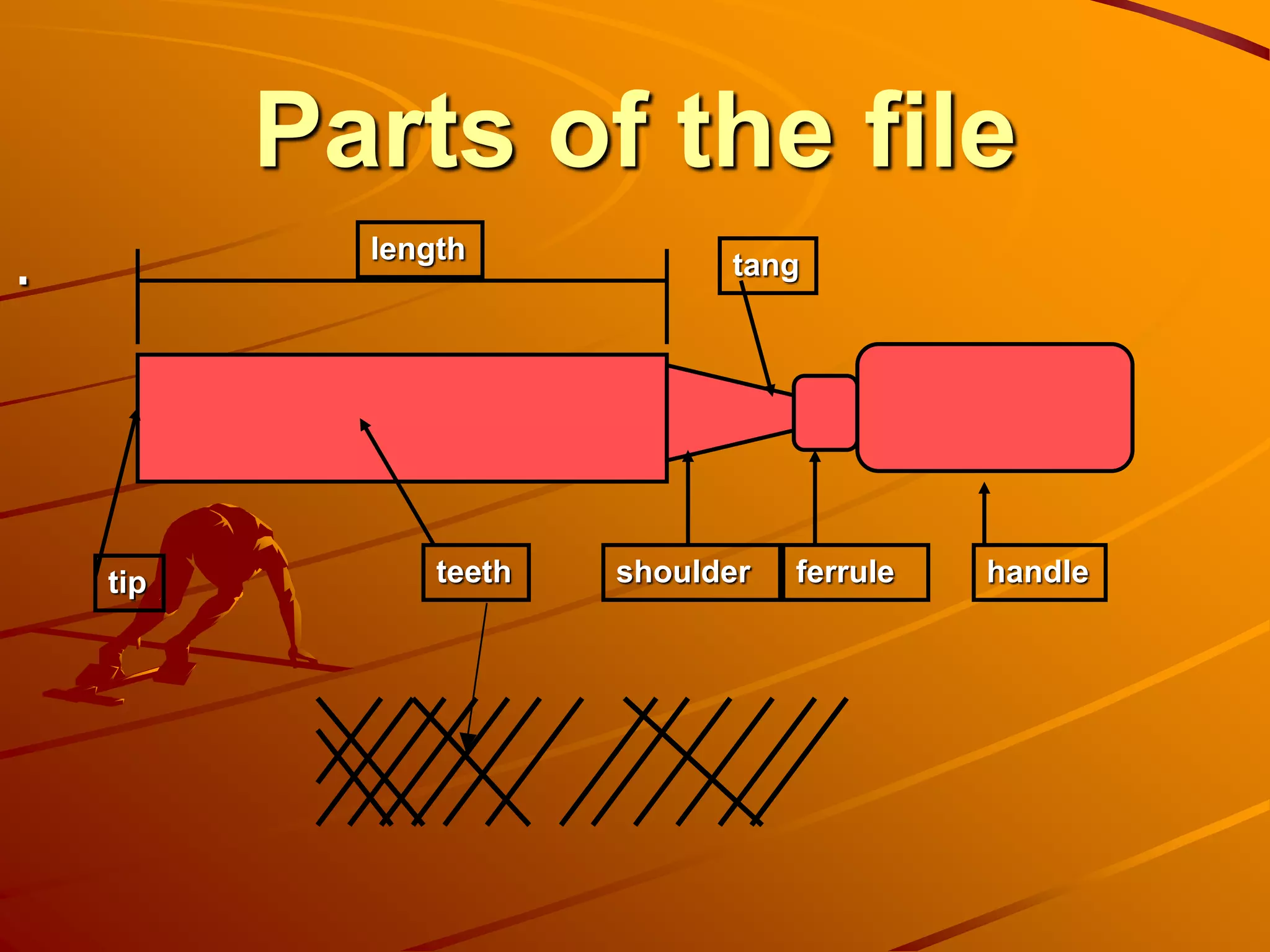

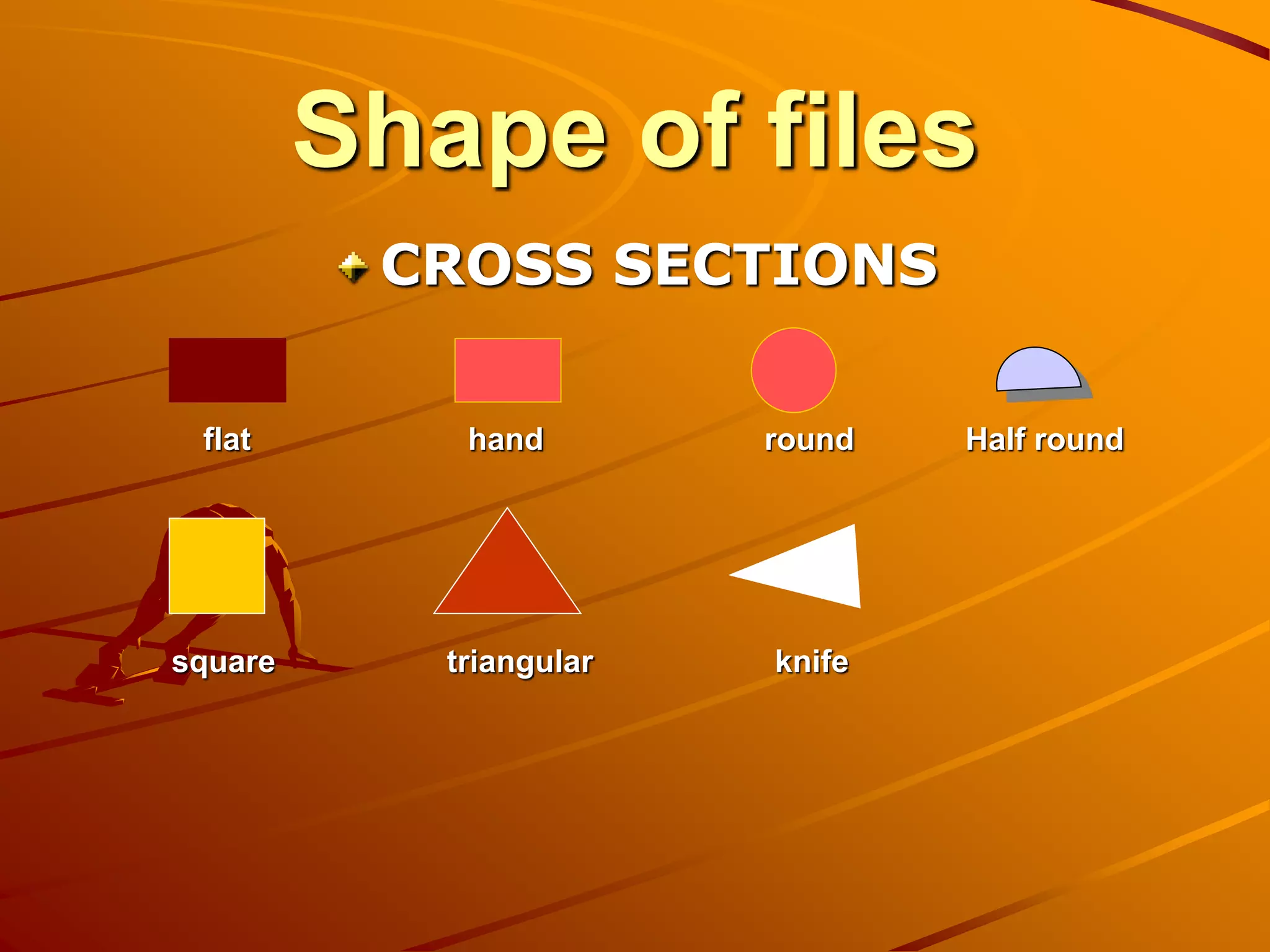

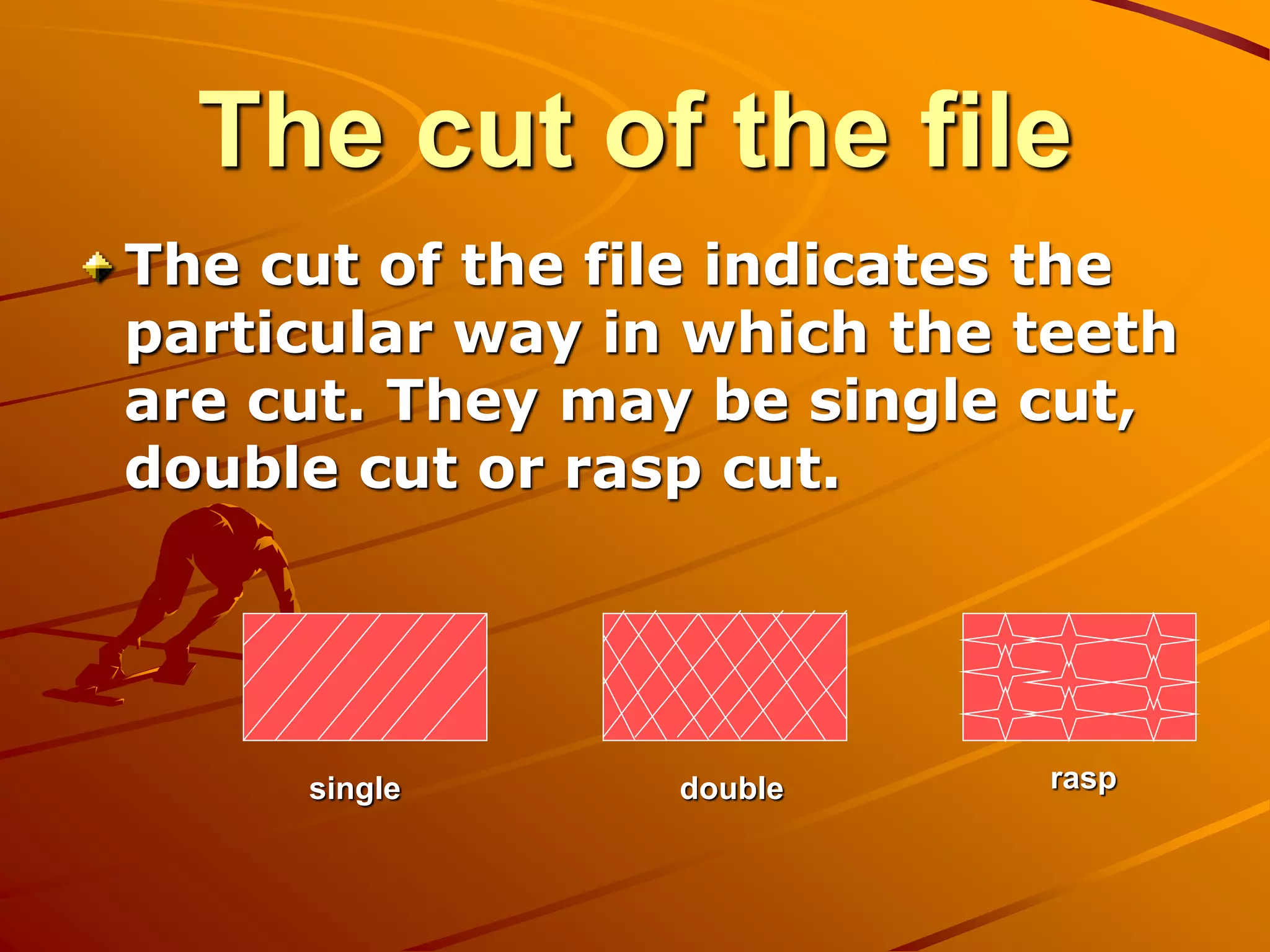

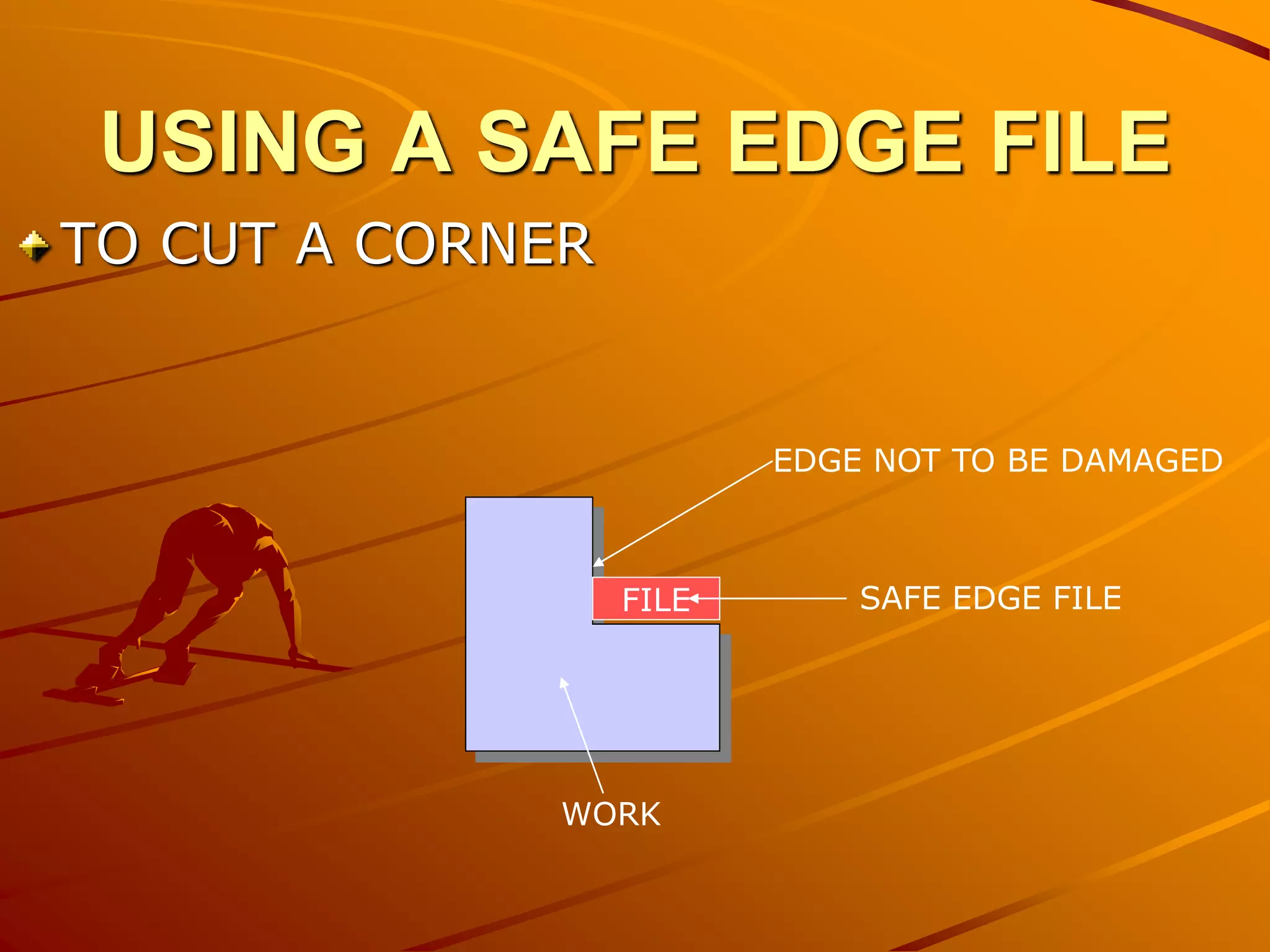

This document provides a lesson on files used in mechanical engineering. It defines files and their parts, different shapes of files, types of files including hand and flat files, methods of filing like cross, draw and profile filing, filing terms including cut and grade, and care of files. The objectives are to be able to identify parts of files, shapes, filing methods, terms, and use files properly to shape metal.