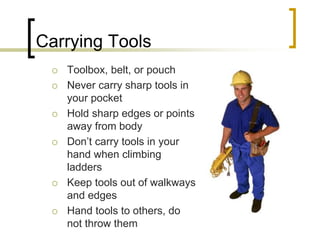

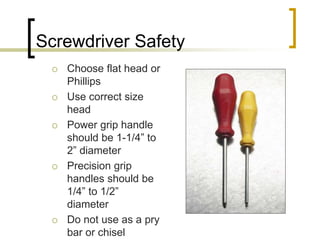

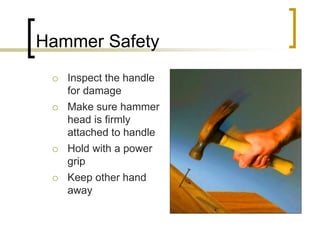

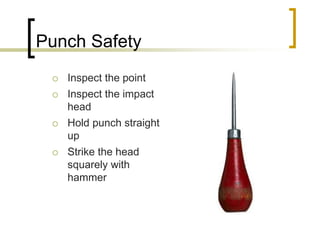

This document provides guidance on hand tool safety. It identifies common hand tools and their associated hazards, such as cuts, punctures, and flying debris. Proper precautions include selecting the right tool for the job, inspecting tools for damage, wearing personal protective equipment, and maintaining tools. Specific safety tips are provided for many types of hand tools, such as using screwdrivers and chisels correctly and not using pliers or wrenches as hammers. The key emphasis is on inspecting tools, using the appropriate tool, and taking precautions to avoid injuries.