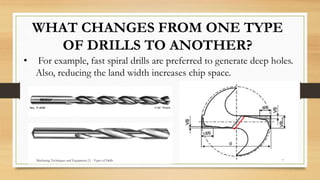

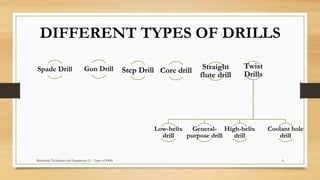

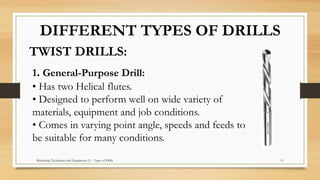

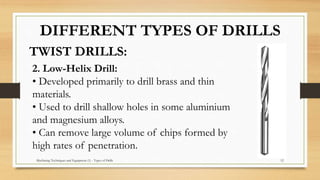

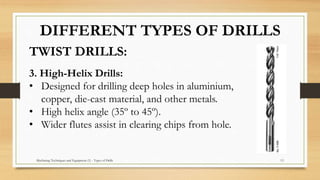

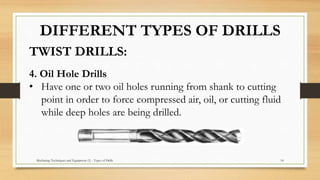

This document discusses different types of drills used in machining. It begins by defining a drill as a double-edged cutting tool used to produce circular holes. Different types of drills are needed depending on the material and purpose of the hole. Characteristics like material, flute length, diameter, and point angle vary between drill types. Common drill types discussed include twist drills, step drills, spade drills, core drills, gun drills, and straight-flute drills. Within twist drills, types like general-purpose drills, low-helix drills, high-helix drills, and oil hole drills are introduced.