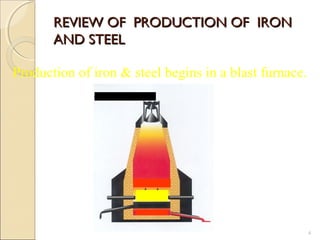

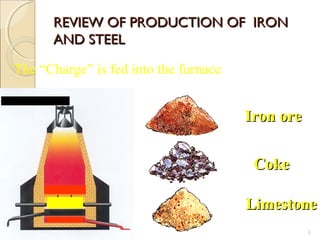

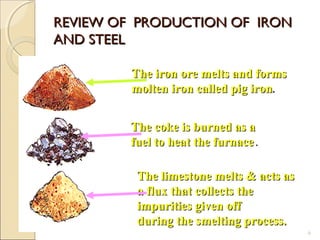

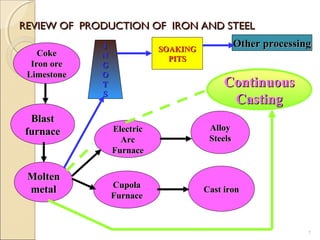

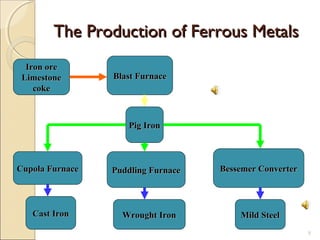

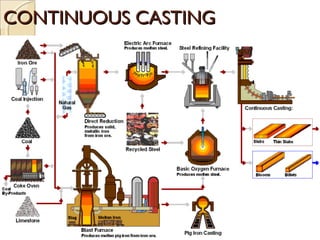

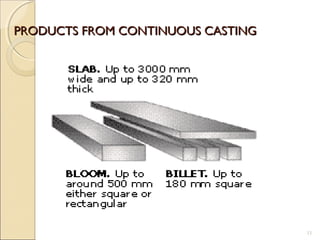

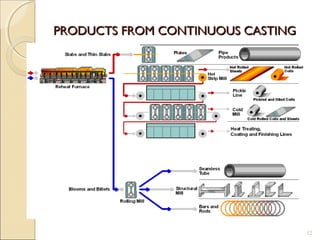

The document discusses the production of ferrous metals like iron and steel. It begins with an overview of the three main ingredients - iron ore, coke, and limestone - that are fed into a blast furnace to produce molten iron or pig iron. The pig iron can then undergo further processing through cupola furnaces or Bessemer converters to produce cast iron or steel. Continuous casting is also discussed, which involves pouring the molten metal directly into molds to produce shapes like blooms, slabs, and billets.