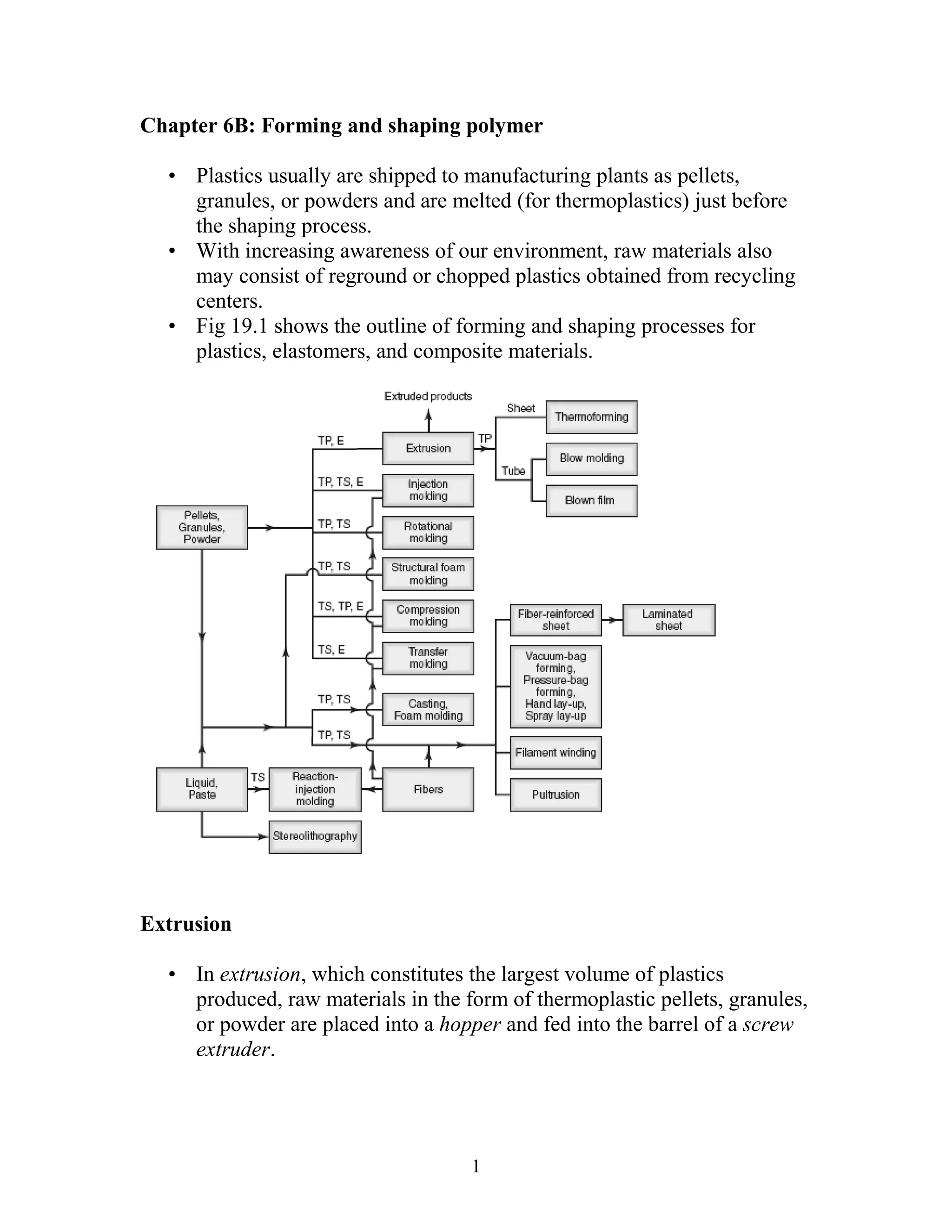

The document summarizes several common polymer forming and shaping processes:

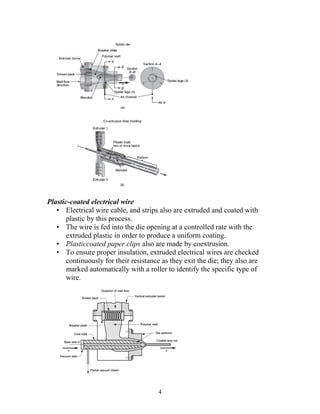

1. Extrusion is the largest production method where raw materials are melted and forced through a die to make shapes. Screw extruders are commonly used.

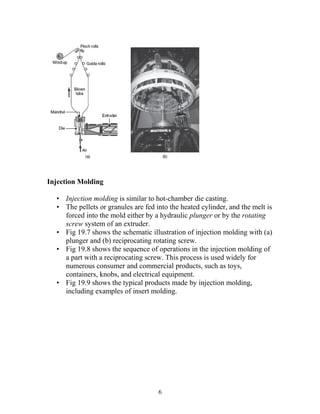

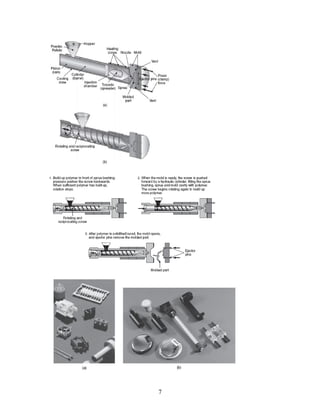

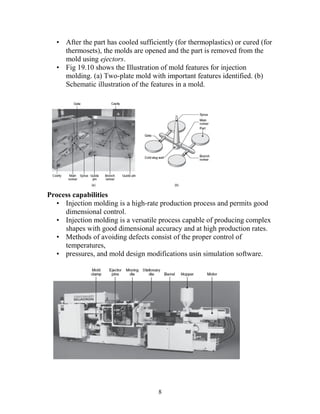

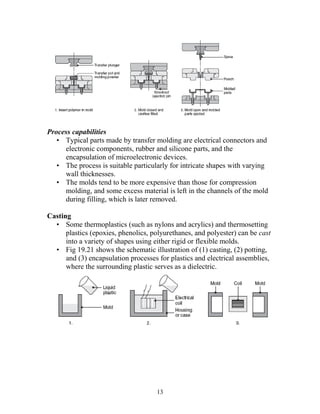

2. Injection molding forces melted polymer into a mold cavity using a hydraulic plunger or screw. It can make complex parts at high volumes.

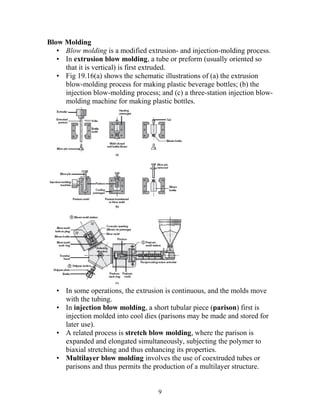

3. Blow molding uses extruded tubes or injection molded parisons that are expanded using air pressure inside closed molds to form hollow shapes like bottles.

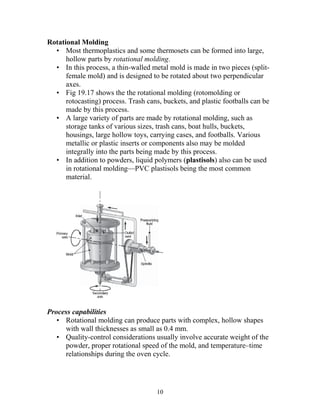

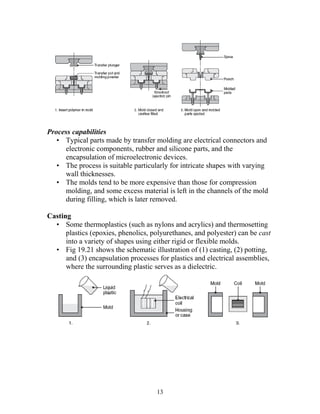

4. Other processes discussed include rotational molding, thermoforming, and compression molding which use heat and pressure to form polymer parts in molds.