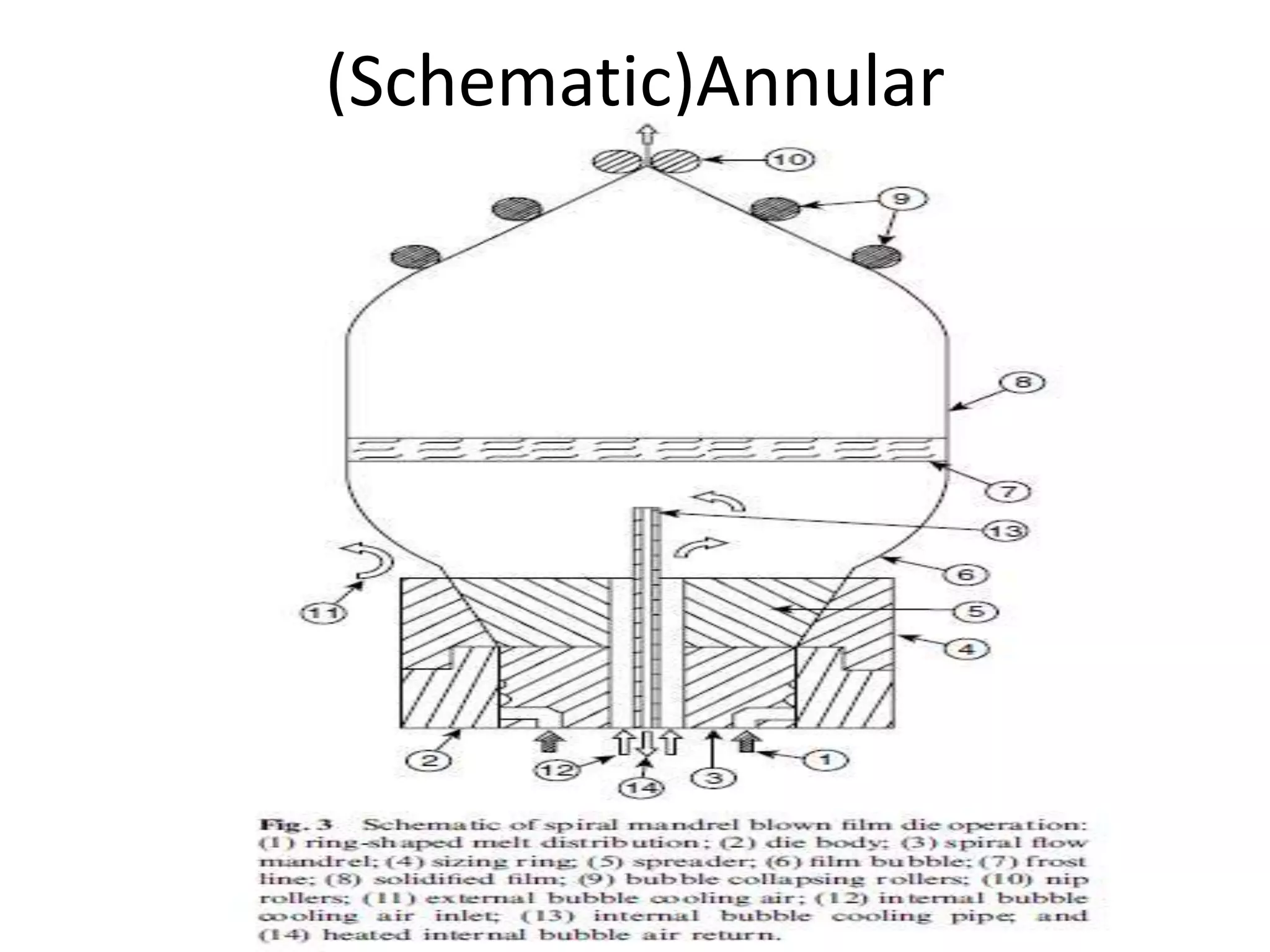

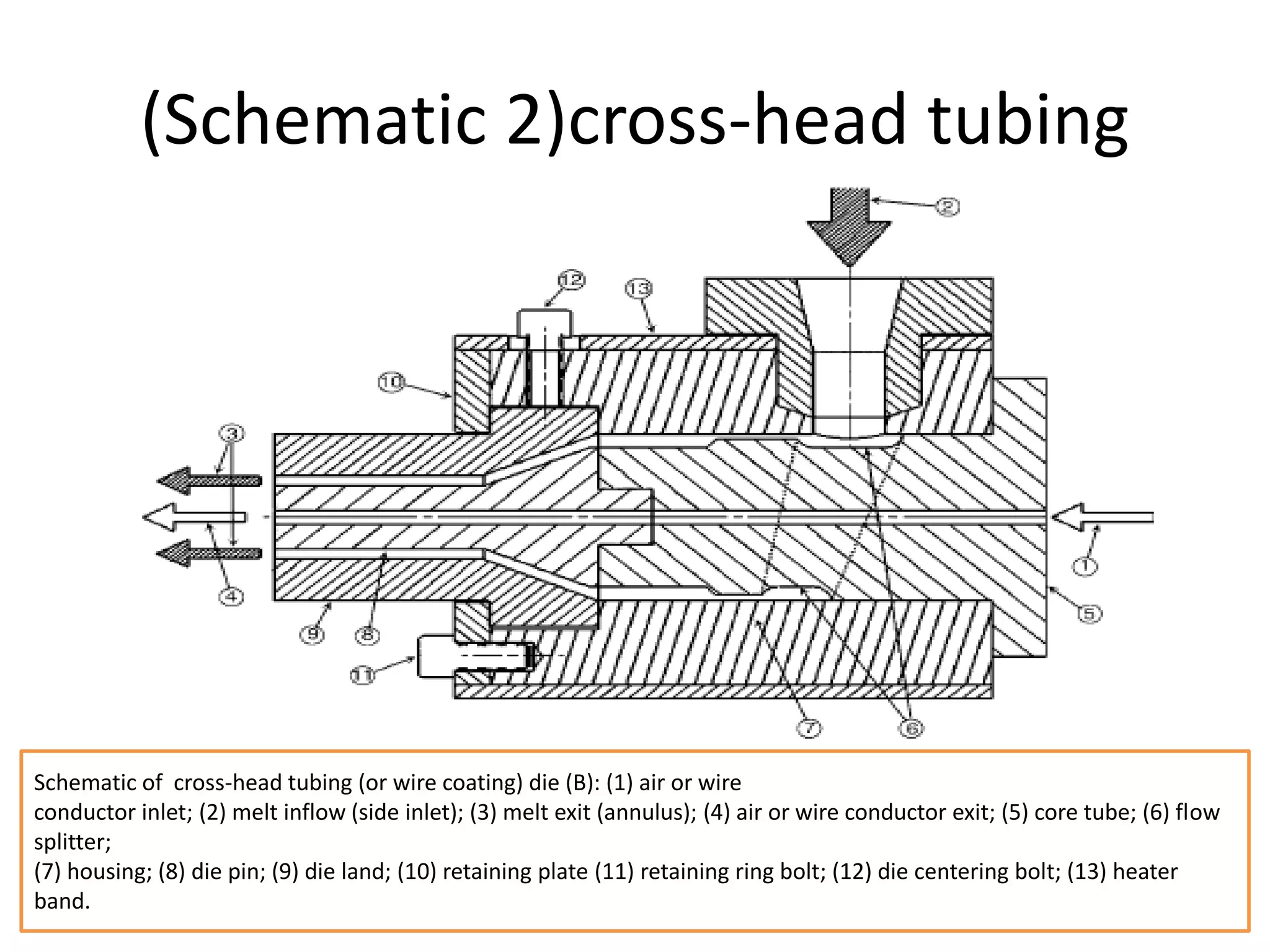

The document discusses the design principles and classifications of extrusion dies, which are essential for producing various products such as sheets, films, pipes, and profiles. It highlights the differences between types of dies, such as inline and cross-head dies, as well as the benefits of profile extrusion and co-extrusion dies. Key concepts include the impact of melt properties on die performance and the resultant product quality.