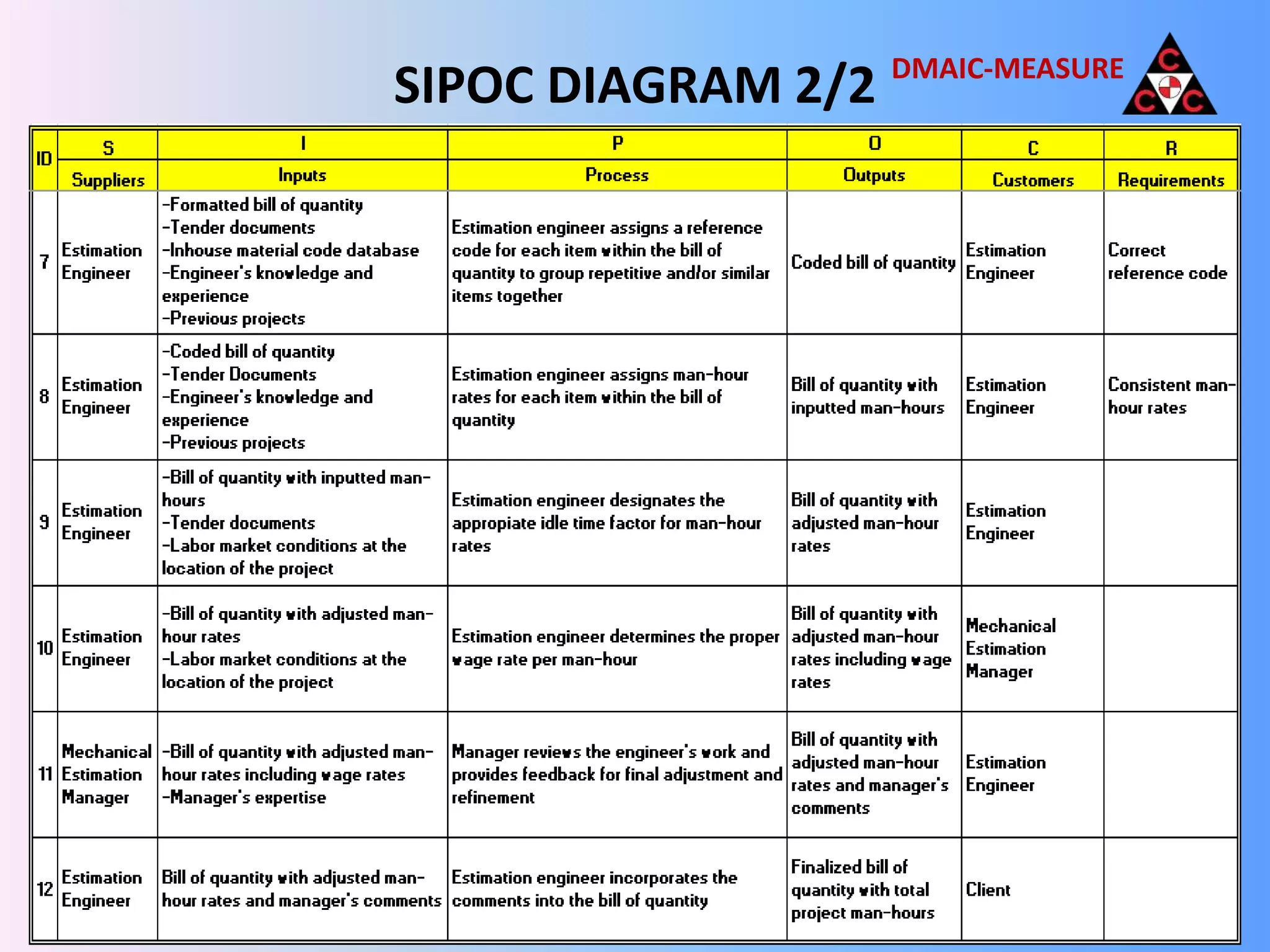

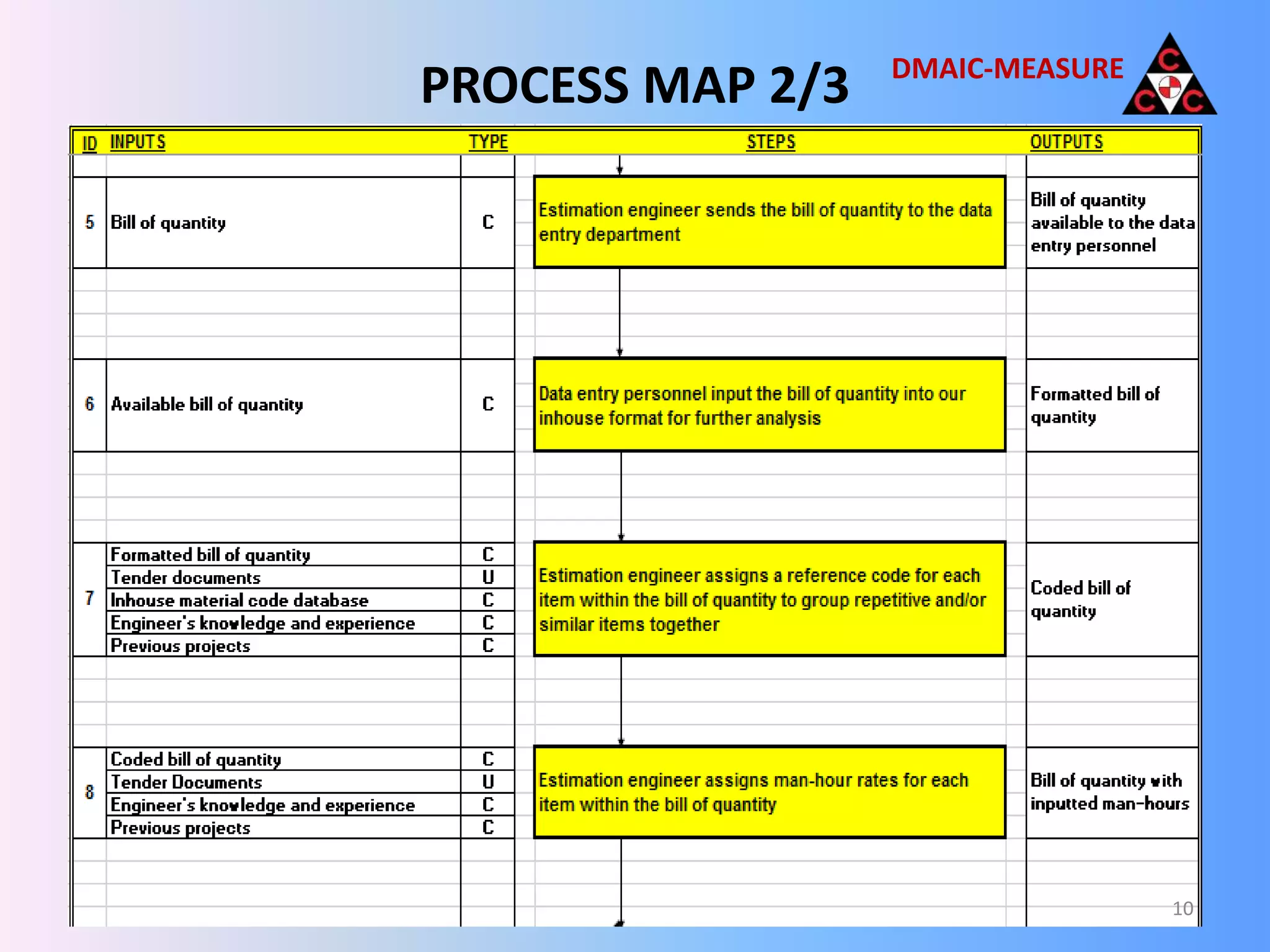

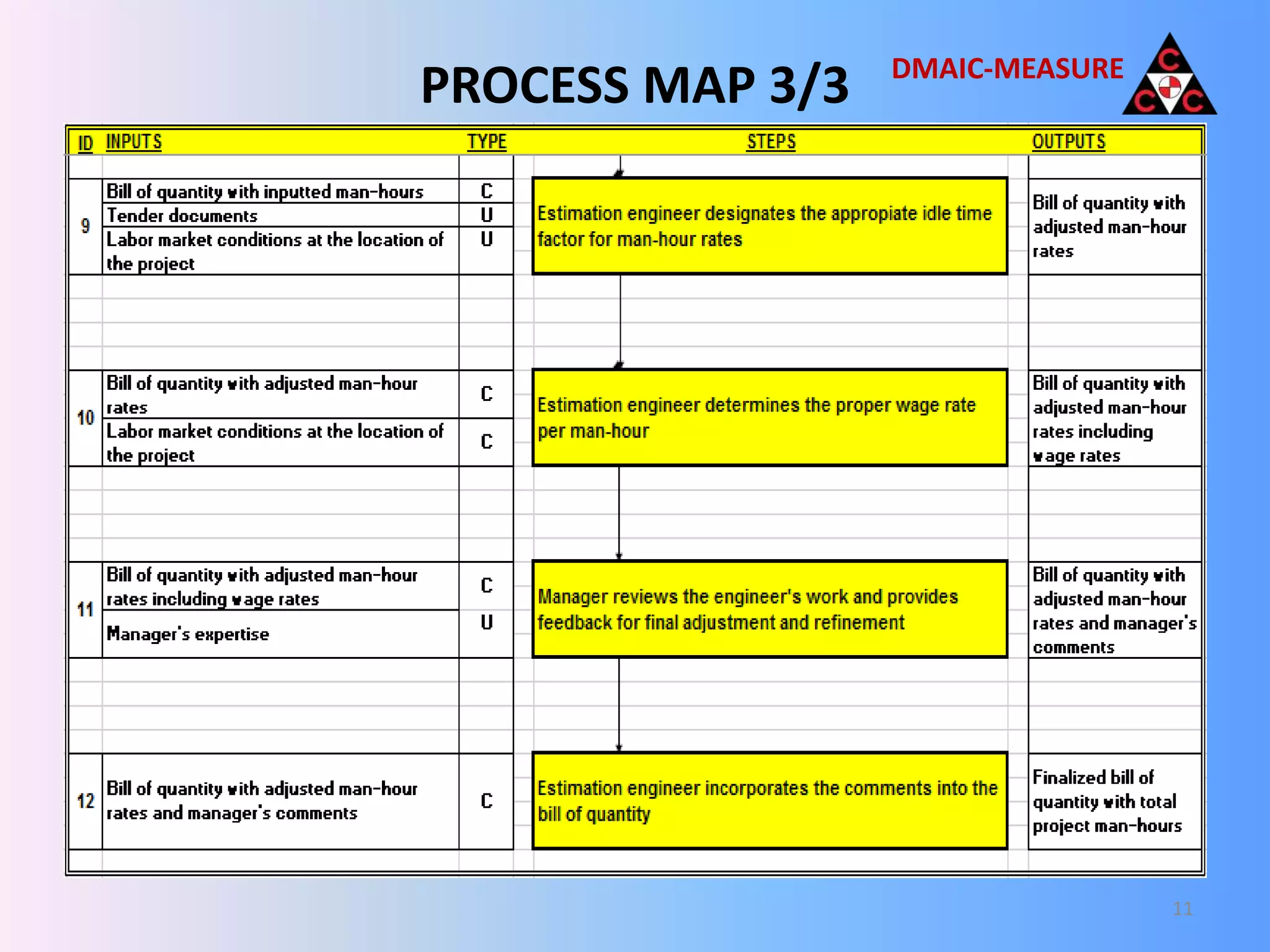

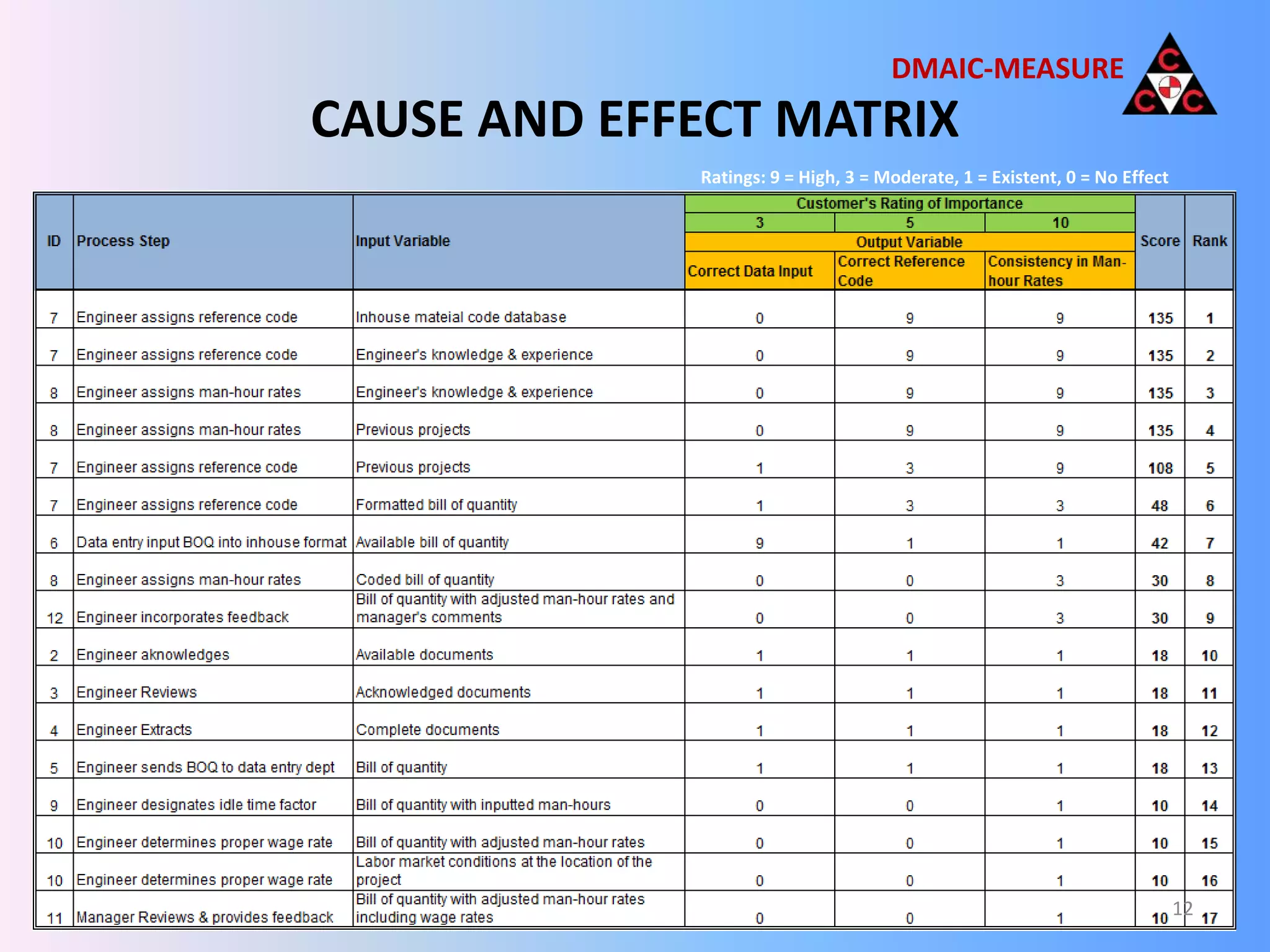

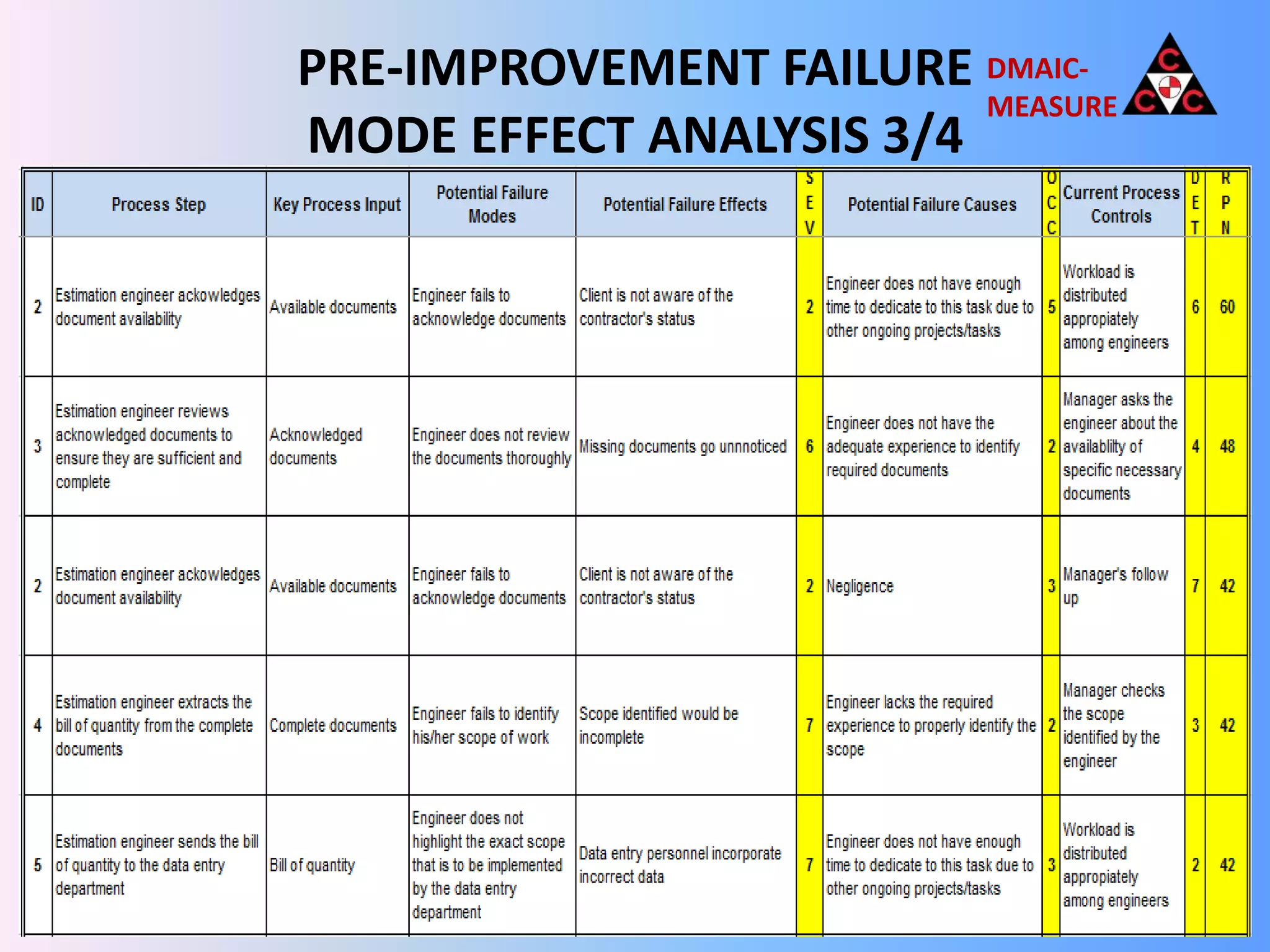

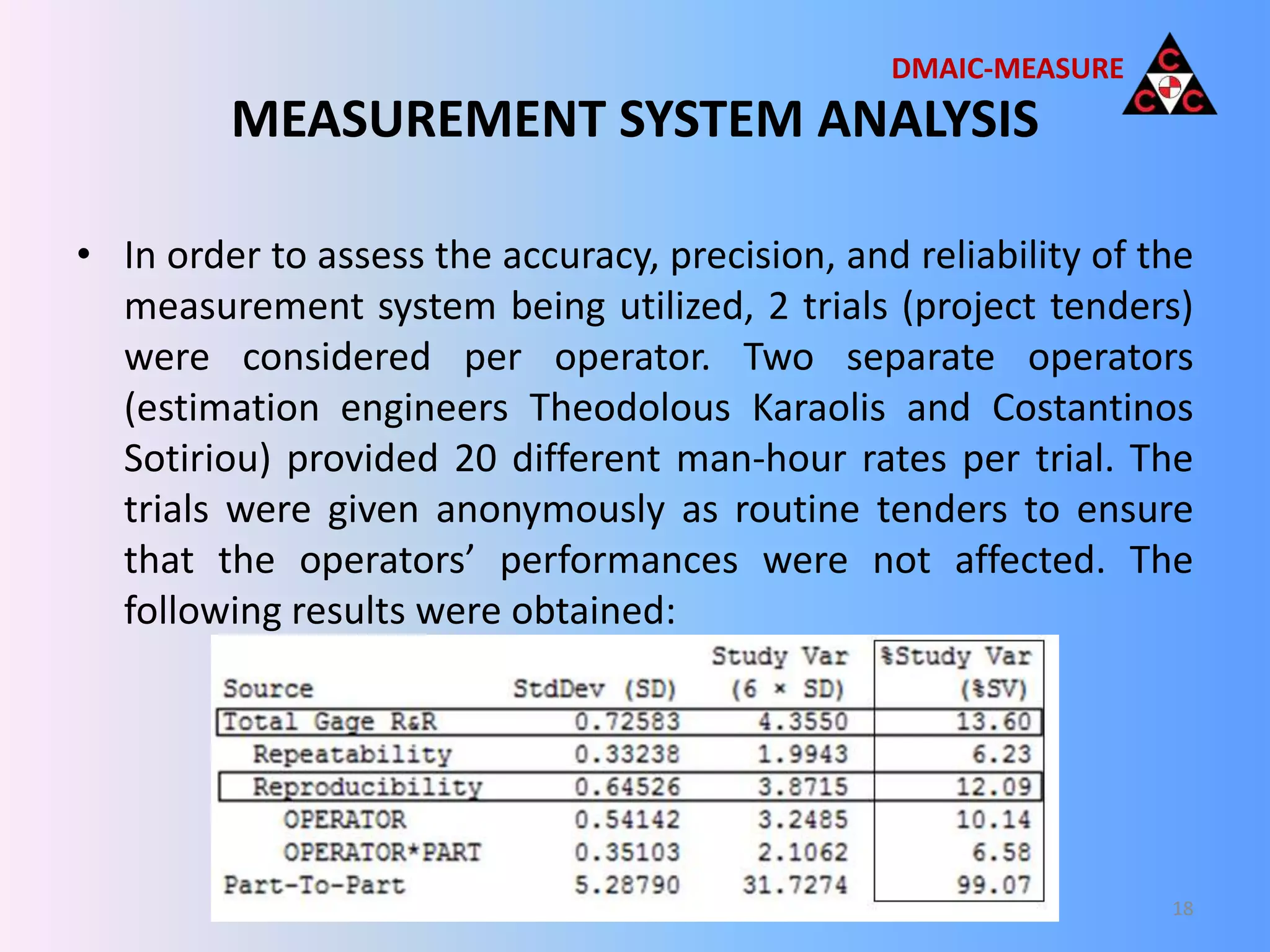

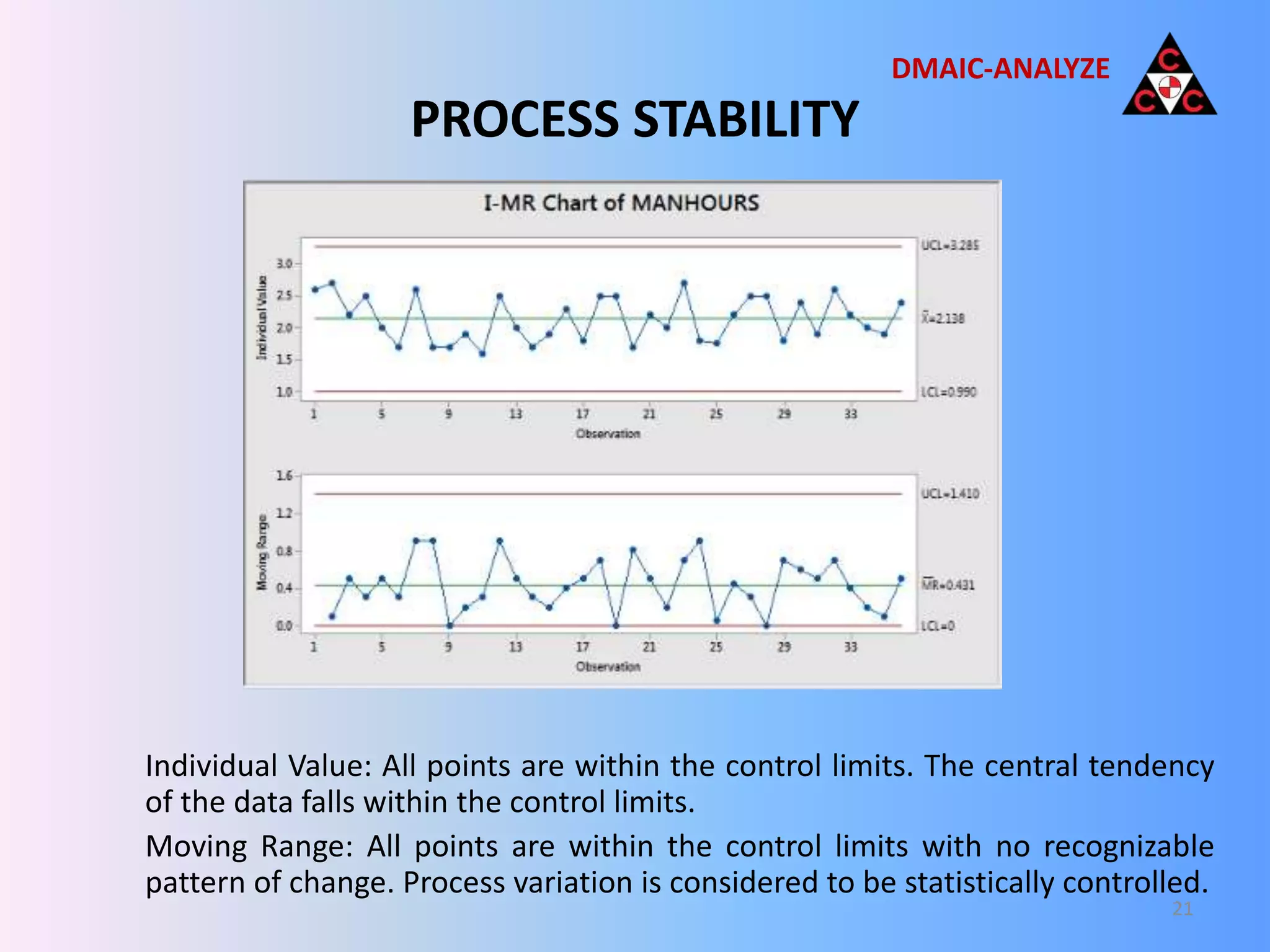

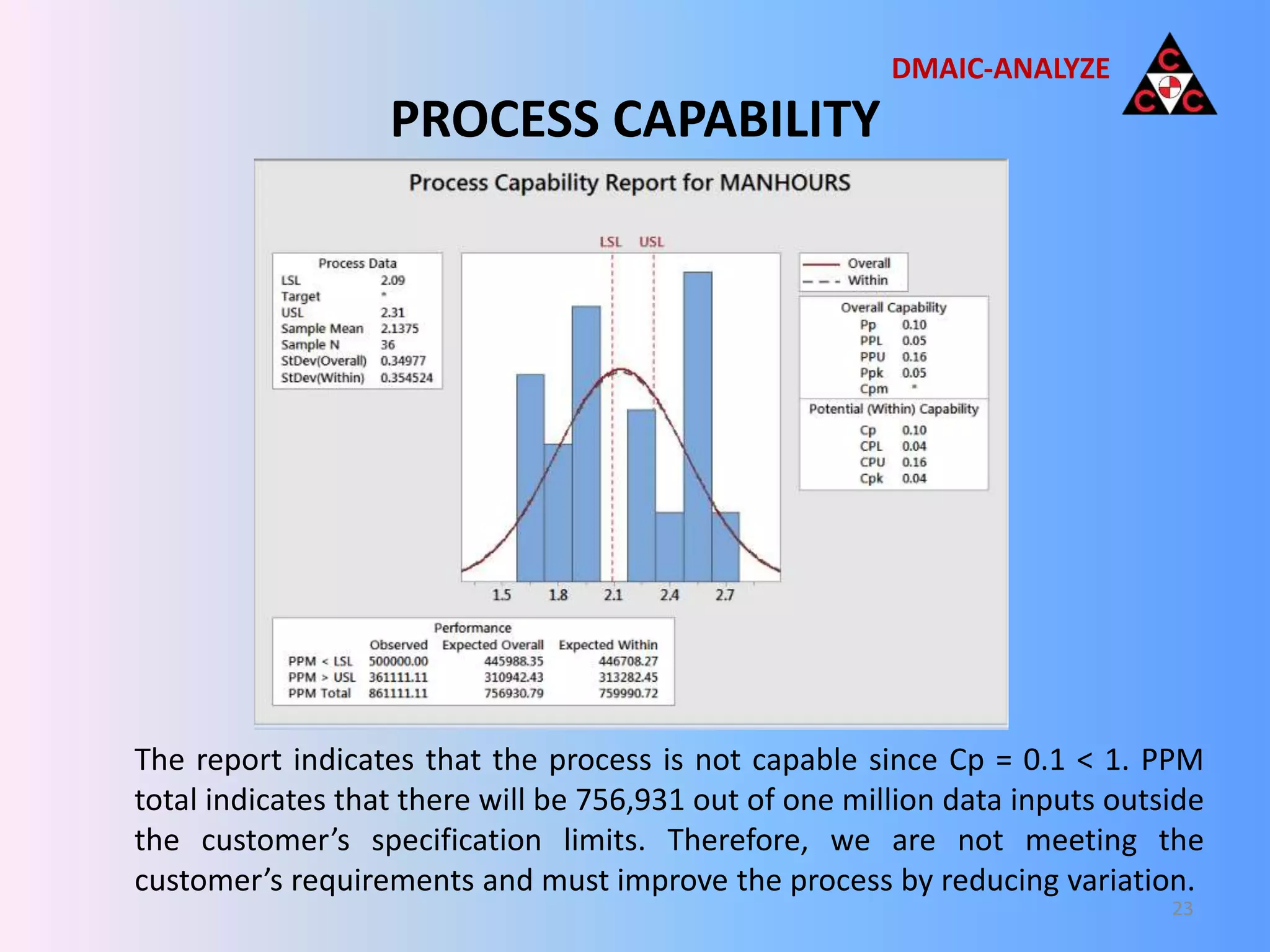

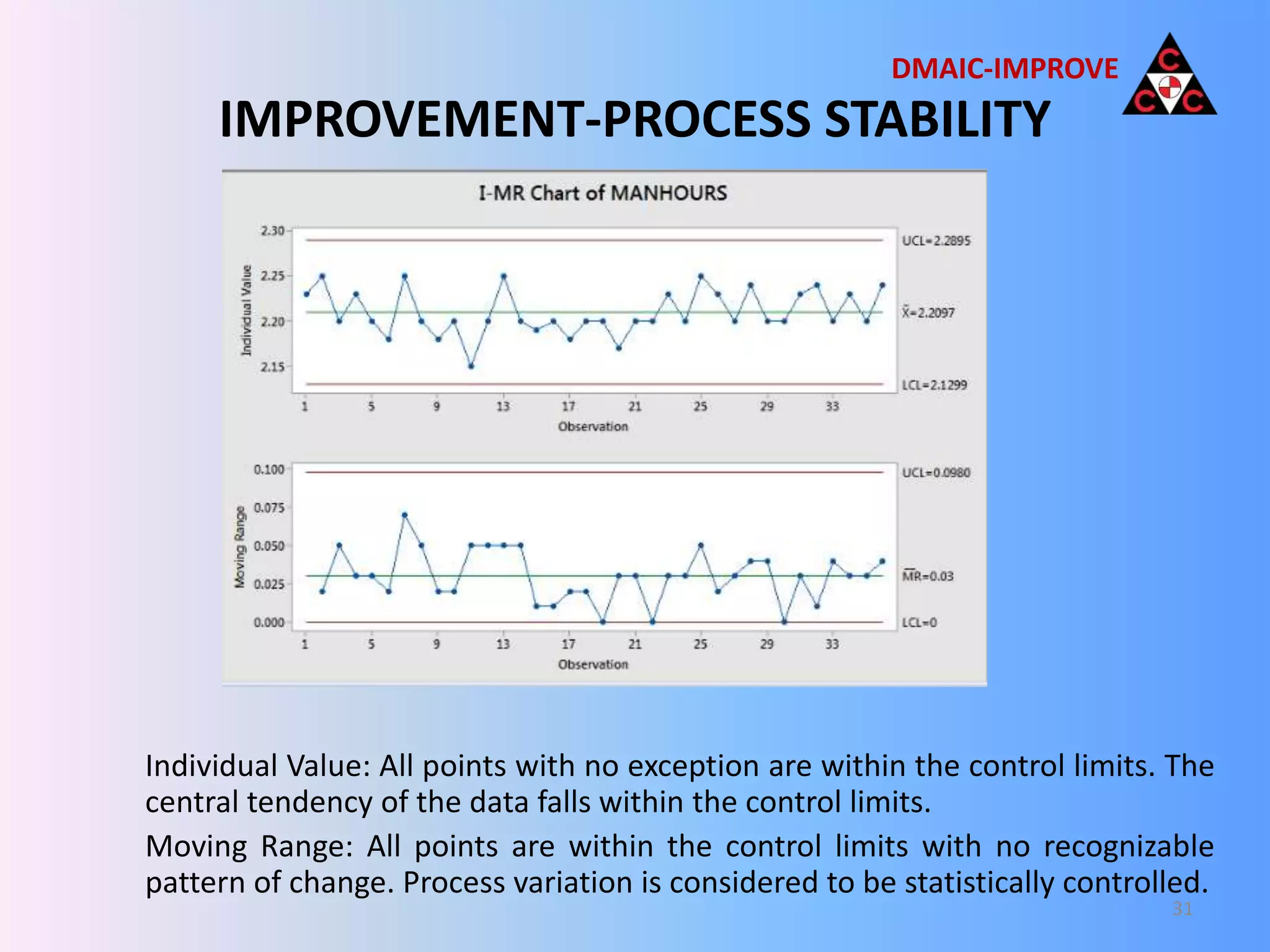

This document outlines a Lean Six Sigma project to reduce variation in man-hour rates for tenders submitted by Consolidated Contractors Company's electromechanical estimation department. The project utilized Six Sigma tools like SIPOC, process mapping, FMEA, and process capability analysis to analyze current performance and identify sources of variation. Improvements like establishing a shared man-hour rate database reduced variation and improved consistency and cost-effectiveness. Standardizing processes and continuously updating the database will sustain gains.