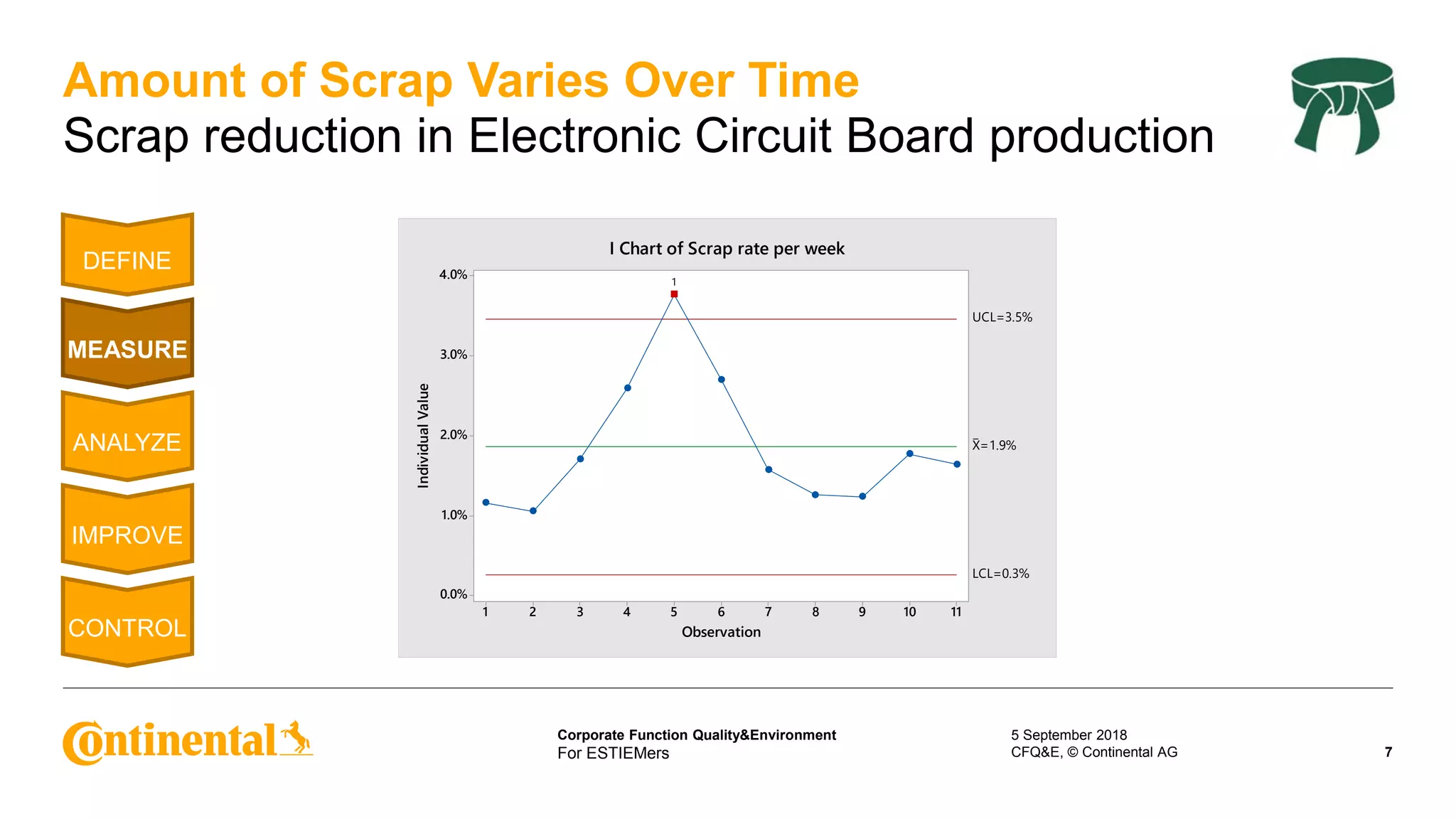

The document presents a Lean Six Sigma project aimed at reducing scrap in electronic circuit board production at Continental Corporation. The project, led by Lassi Uusitalo, identified root causes of defects leading to customer returns and implemented a structured DMAIC approach. Key findings included various mechanical damages during the production process, with a specific focus on connector-related issues and the need for recalibration of equipment to enhance production quality.