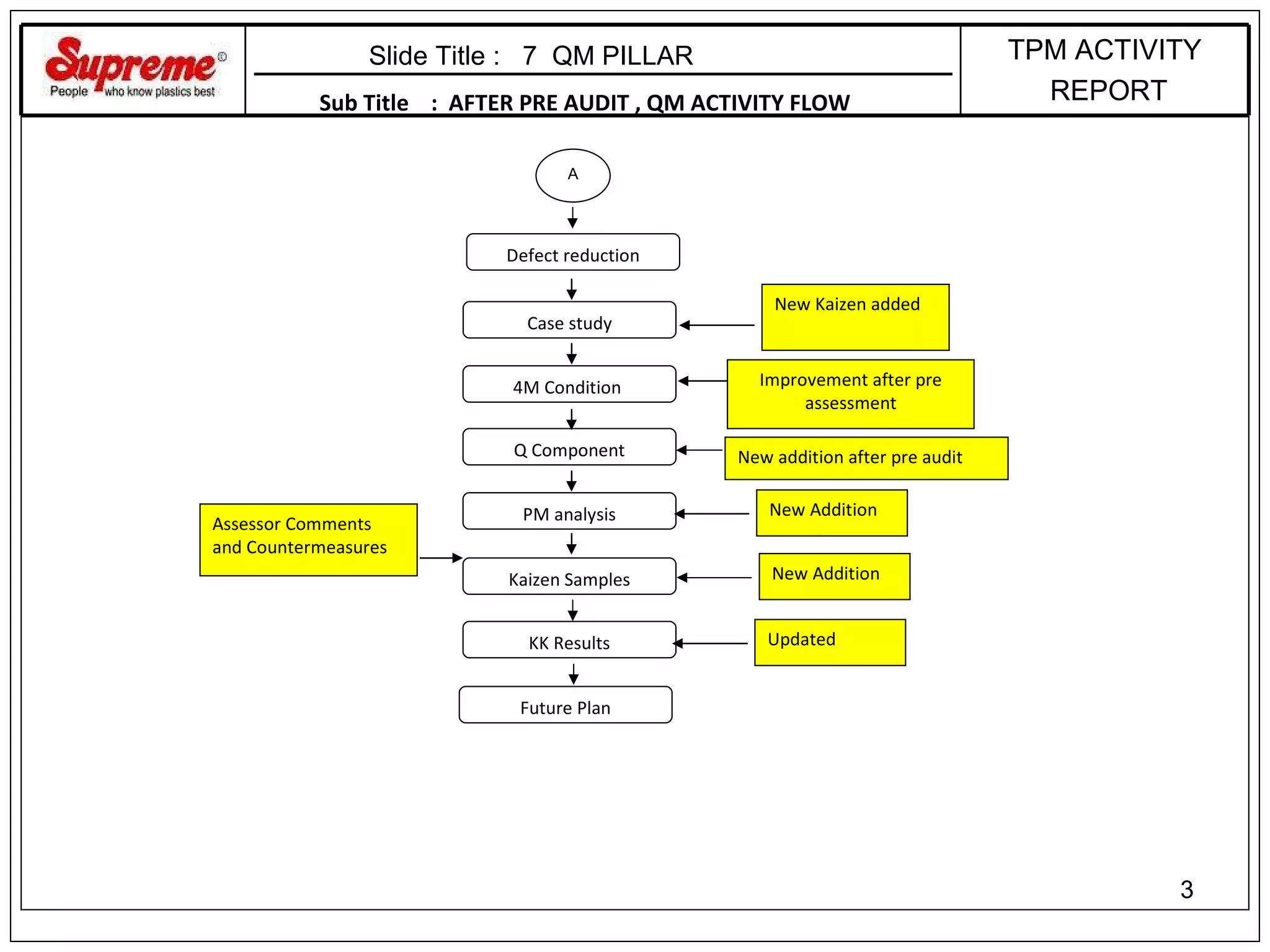

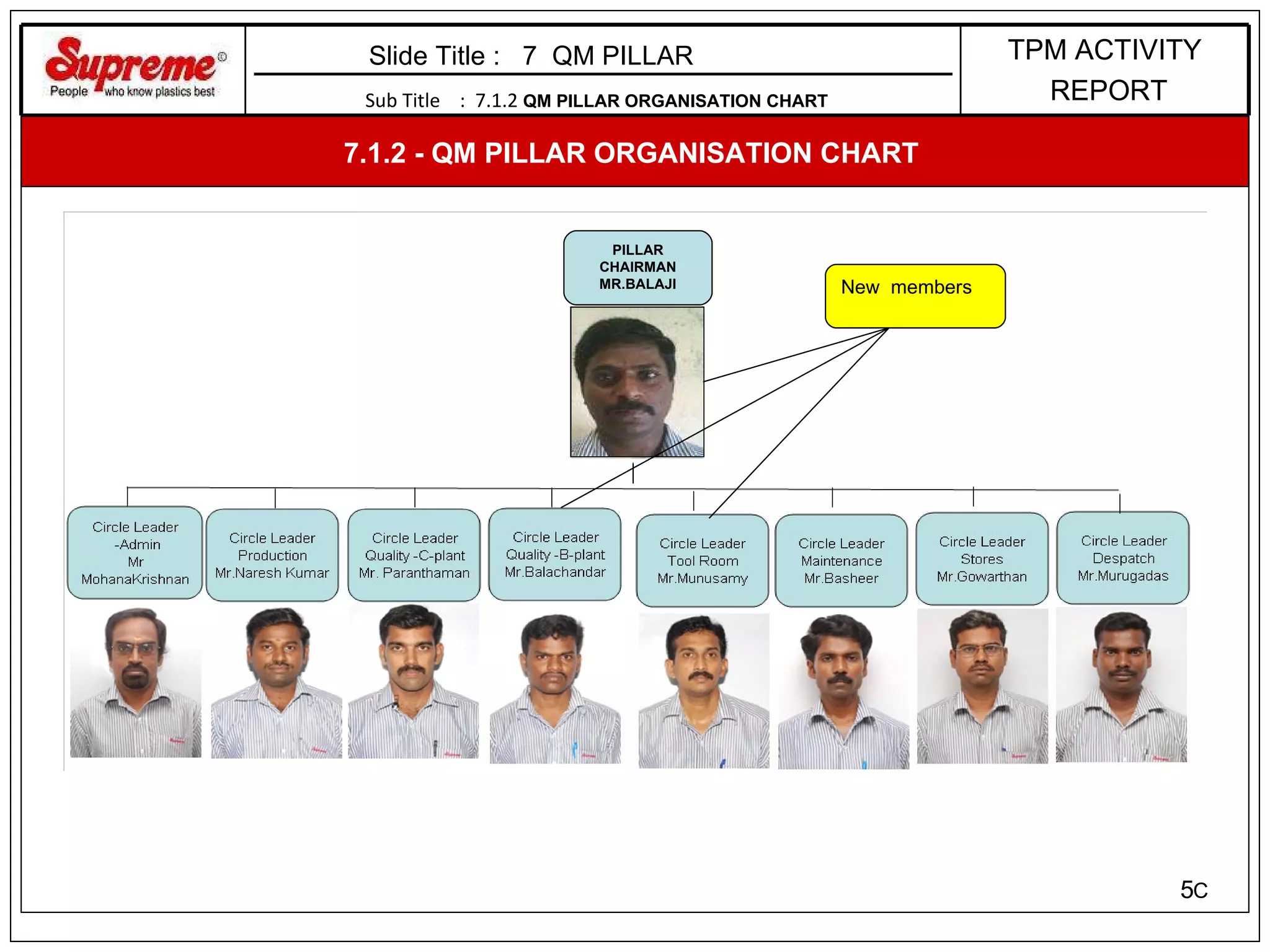

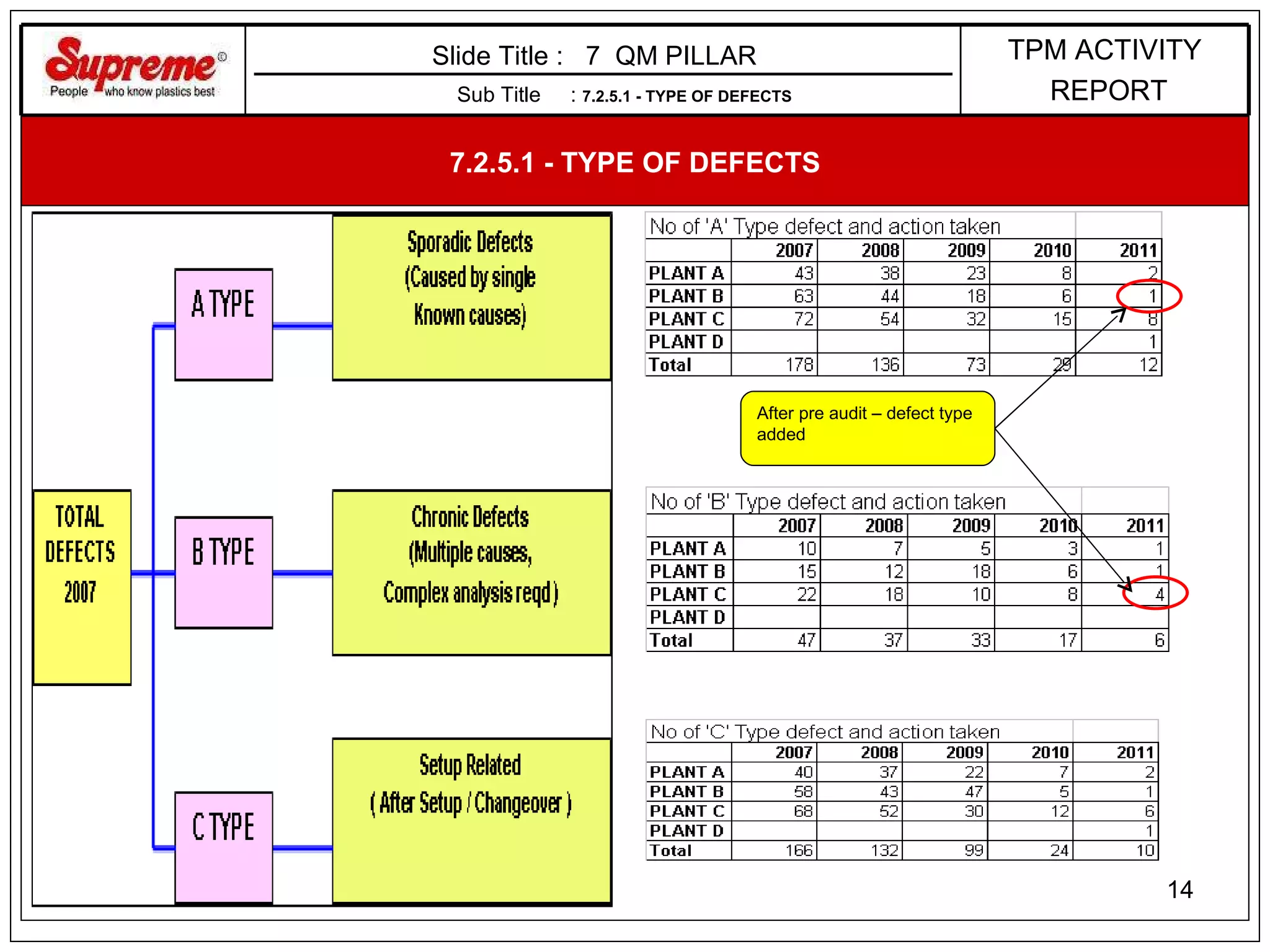

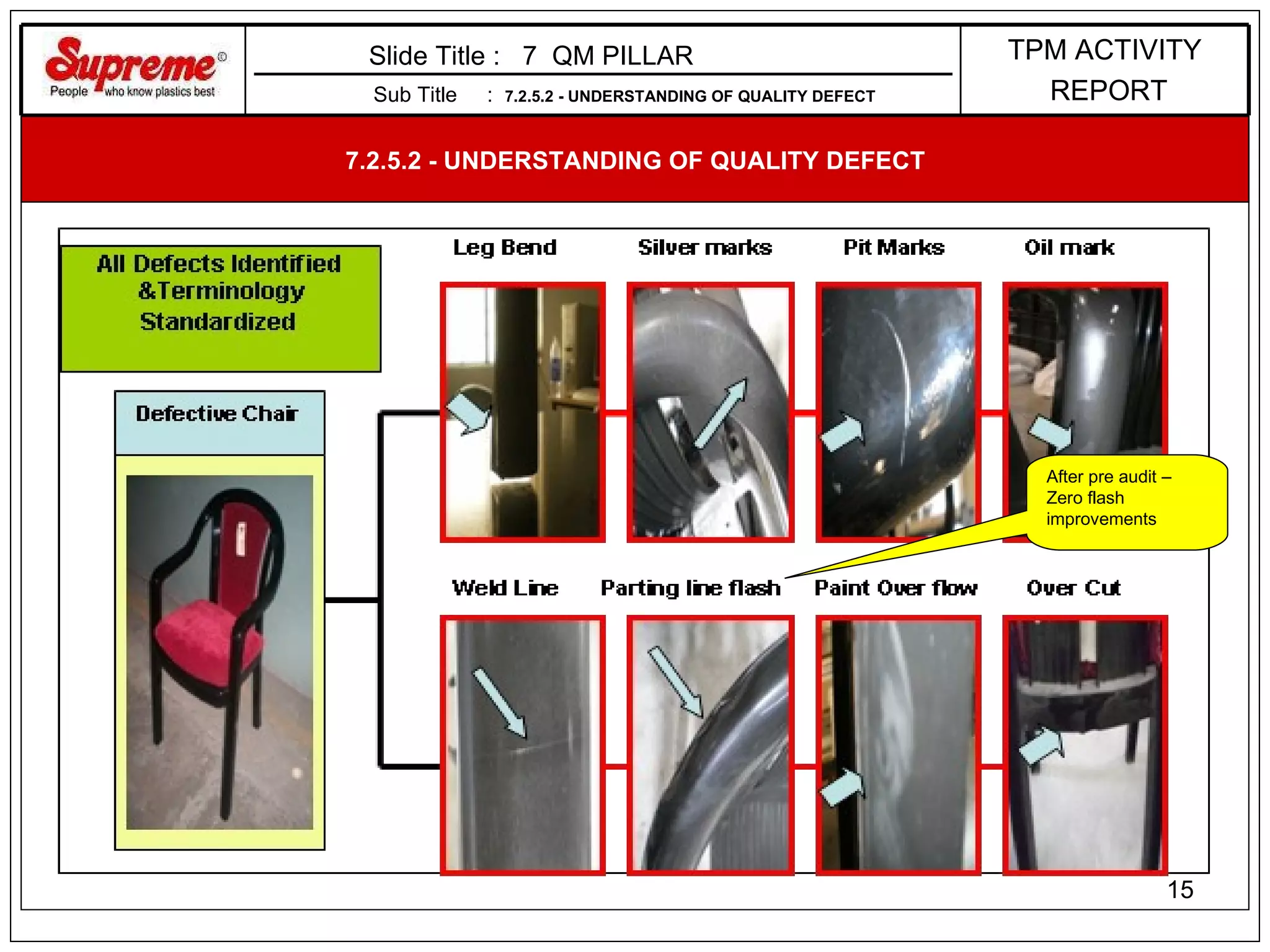

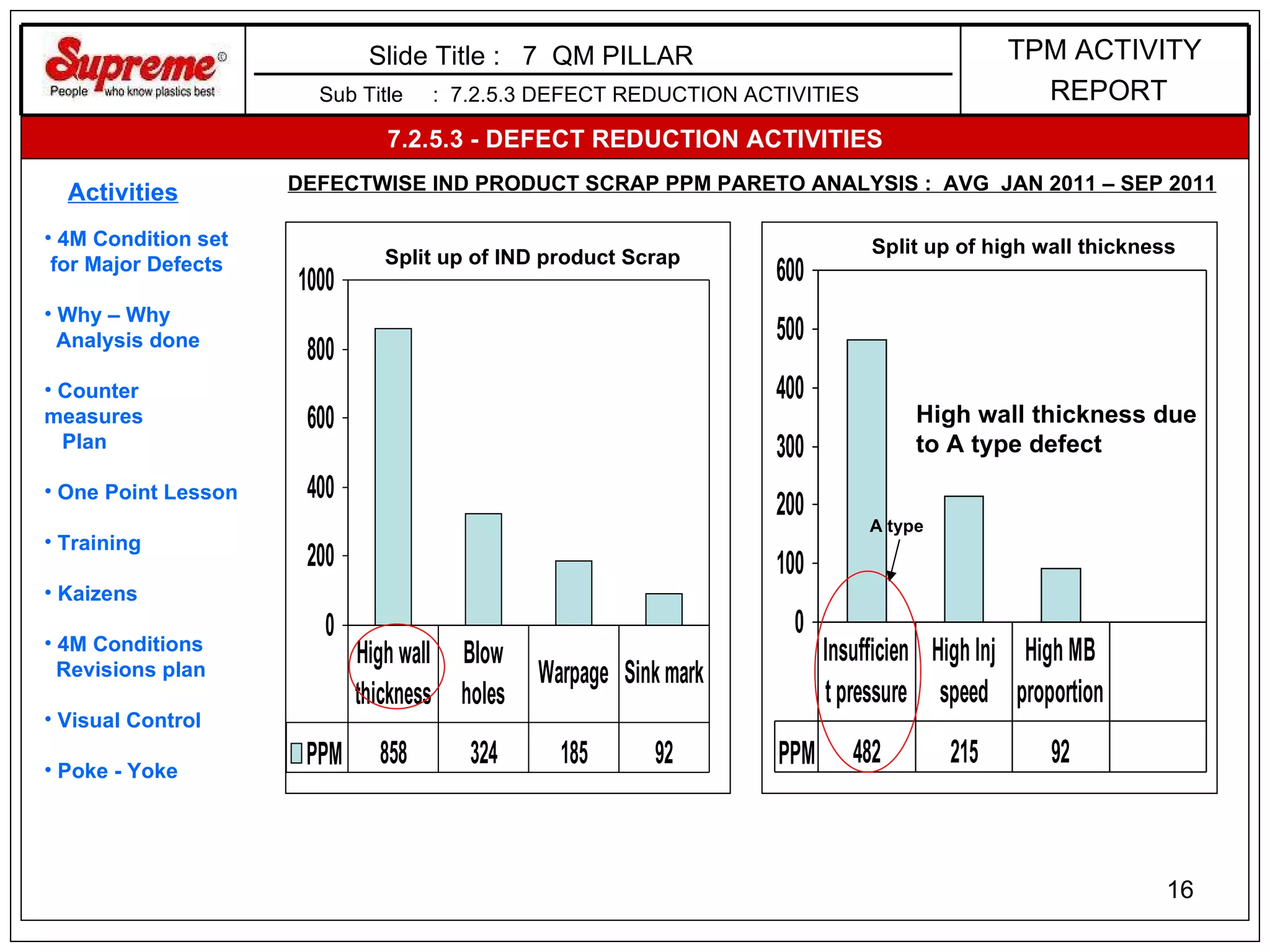

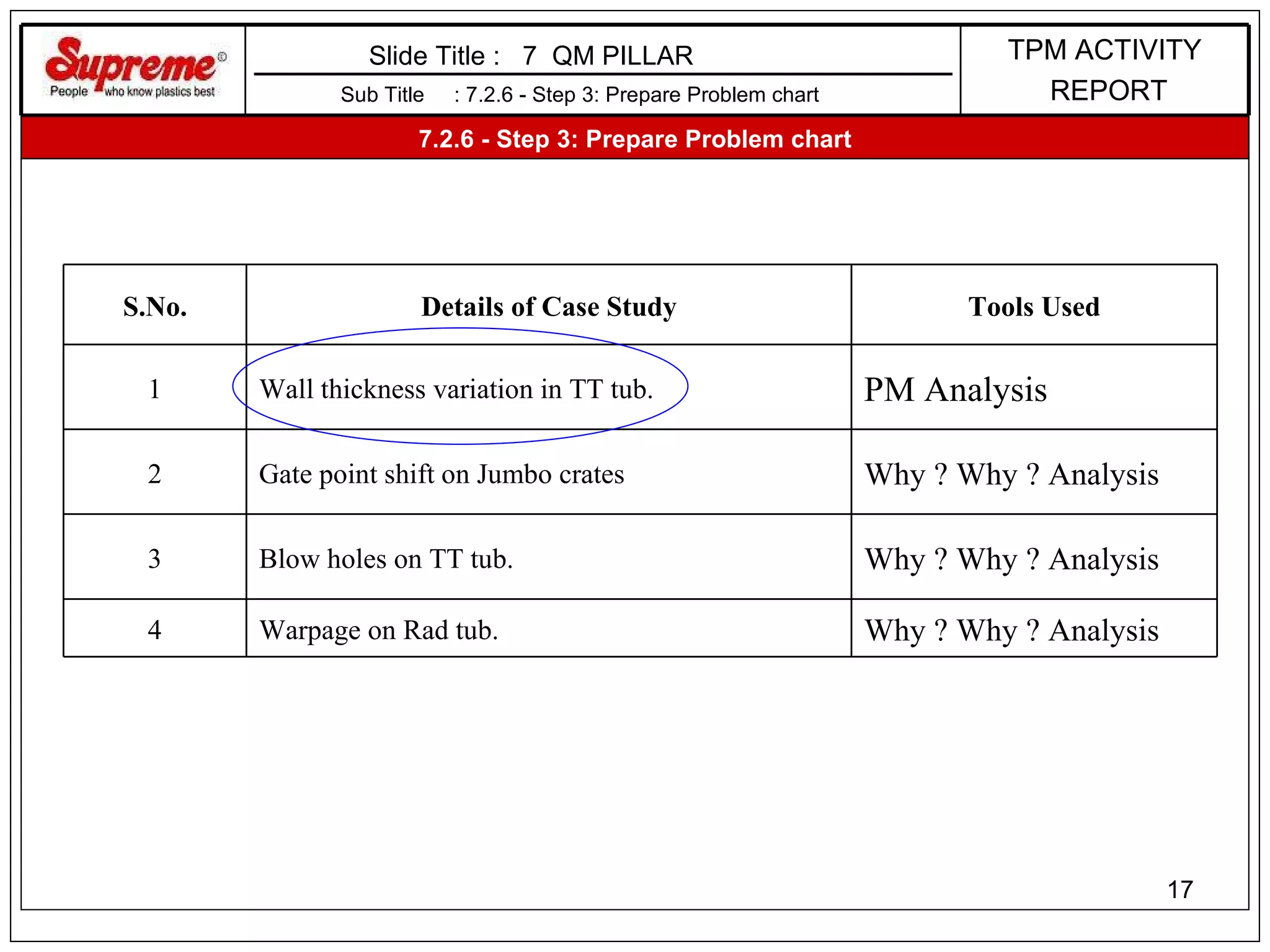

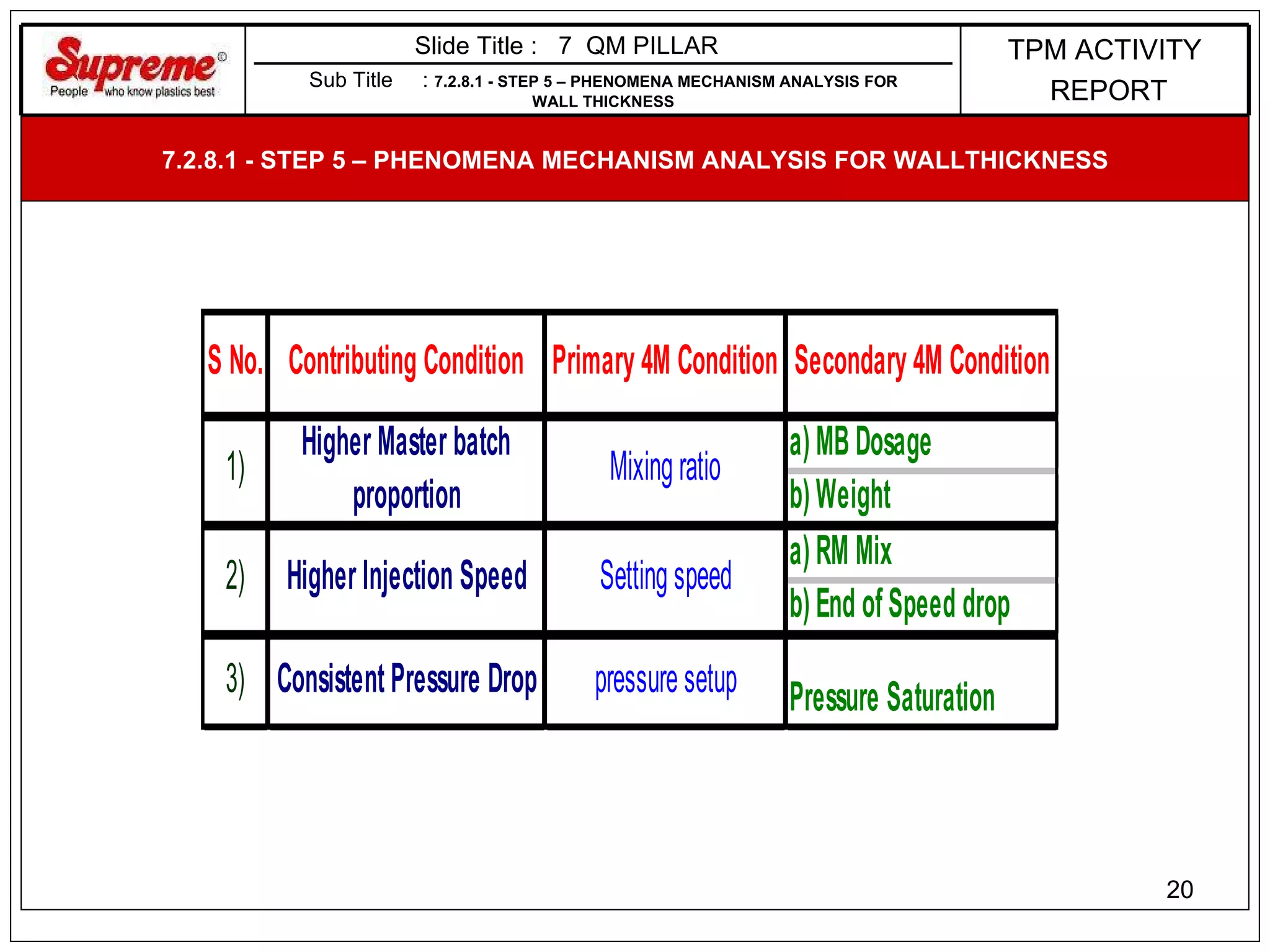

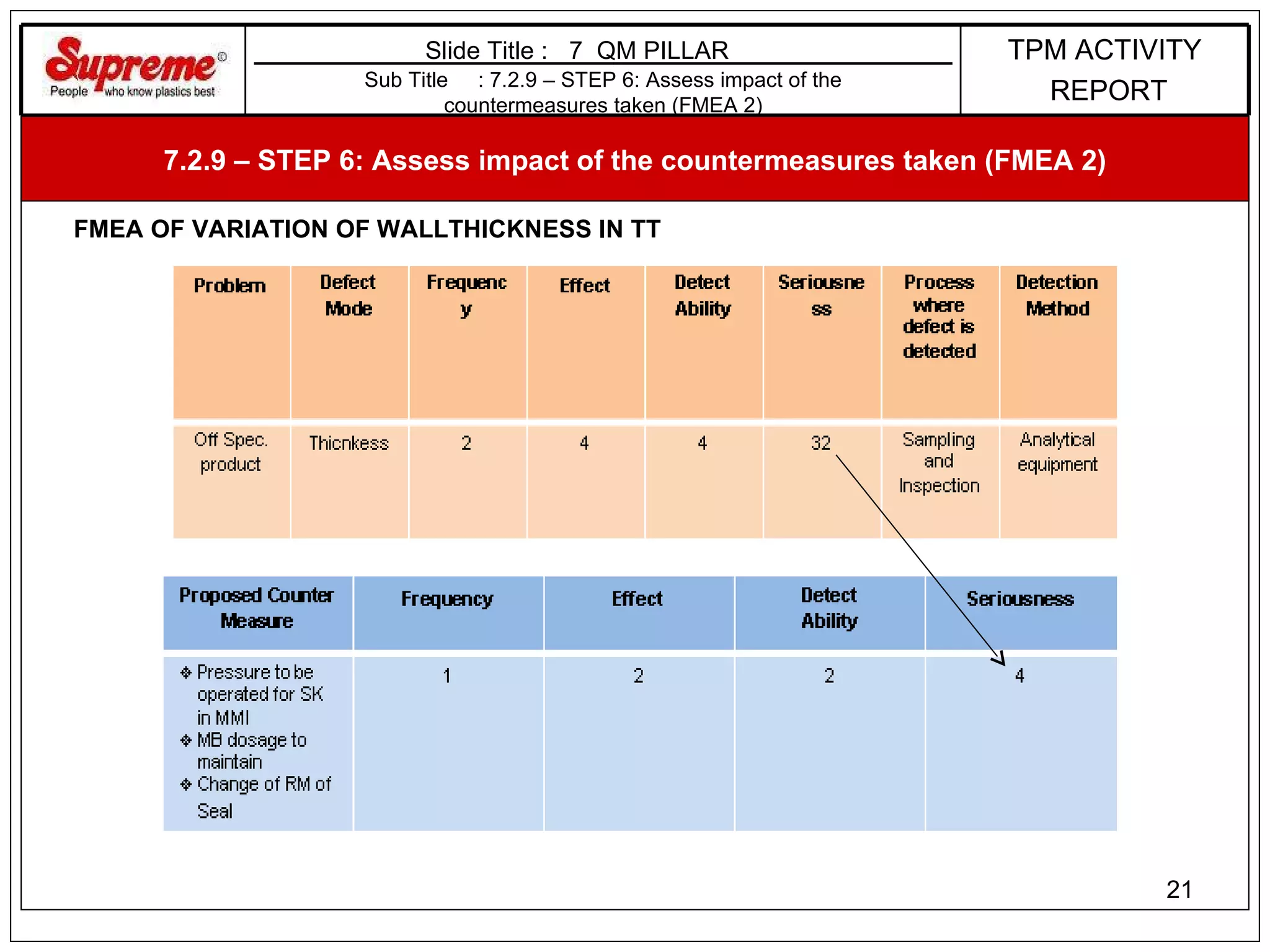

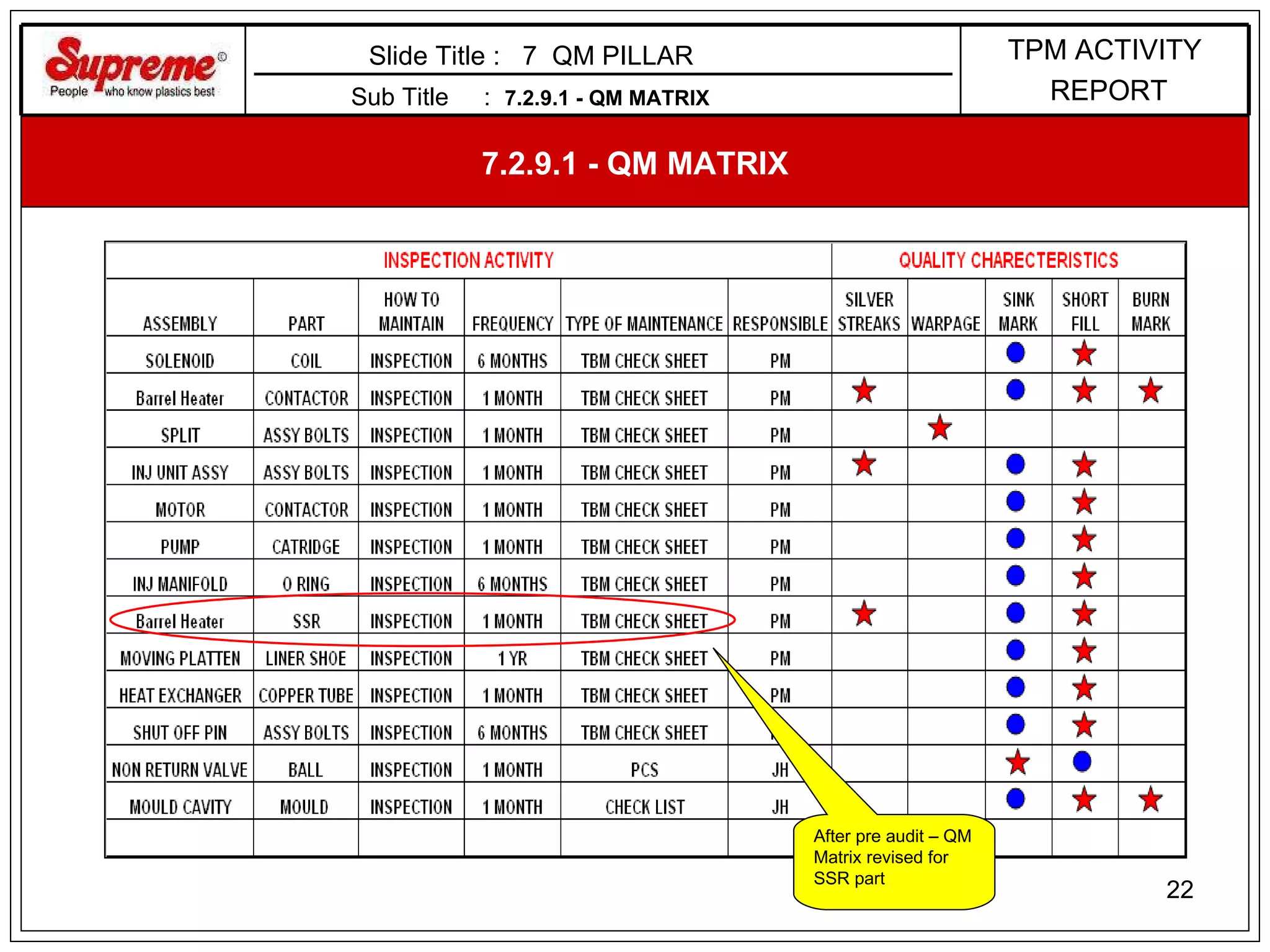

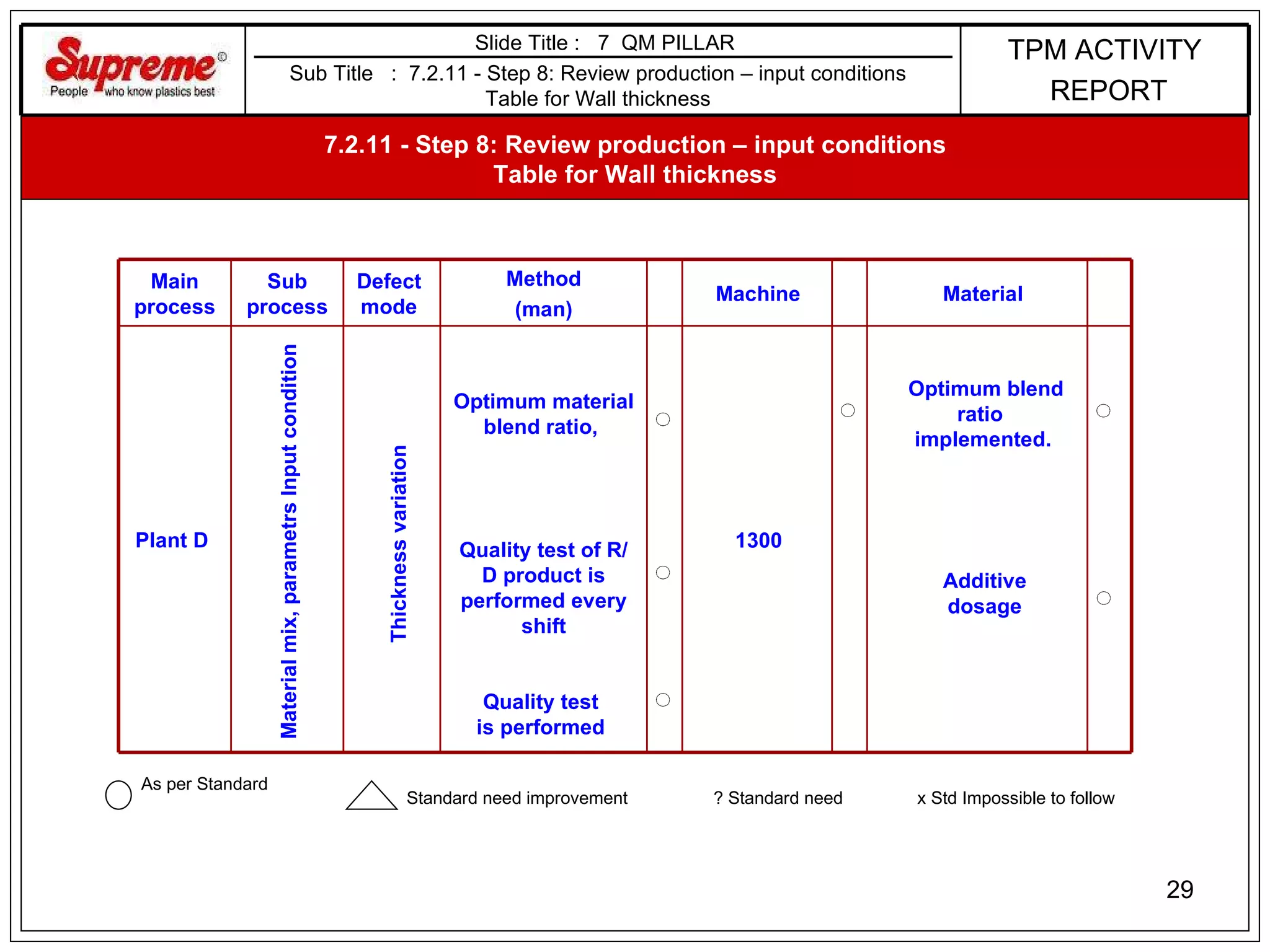

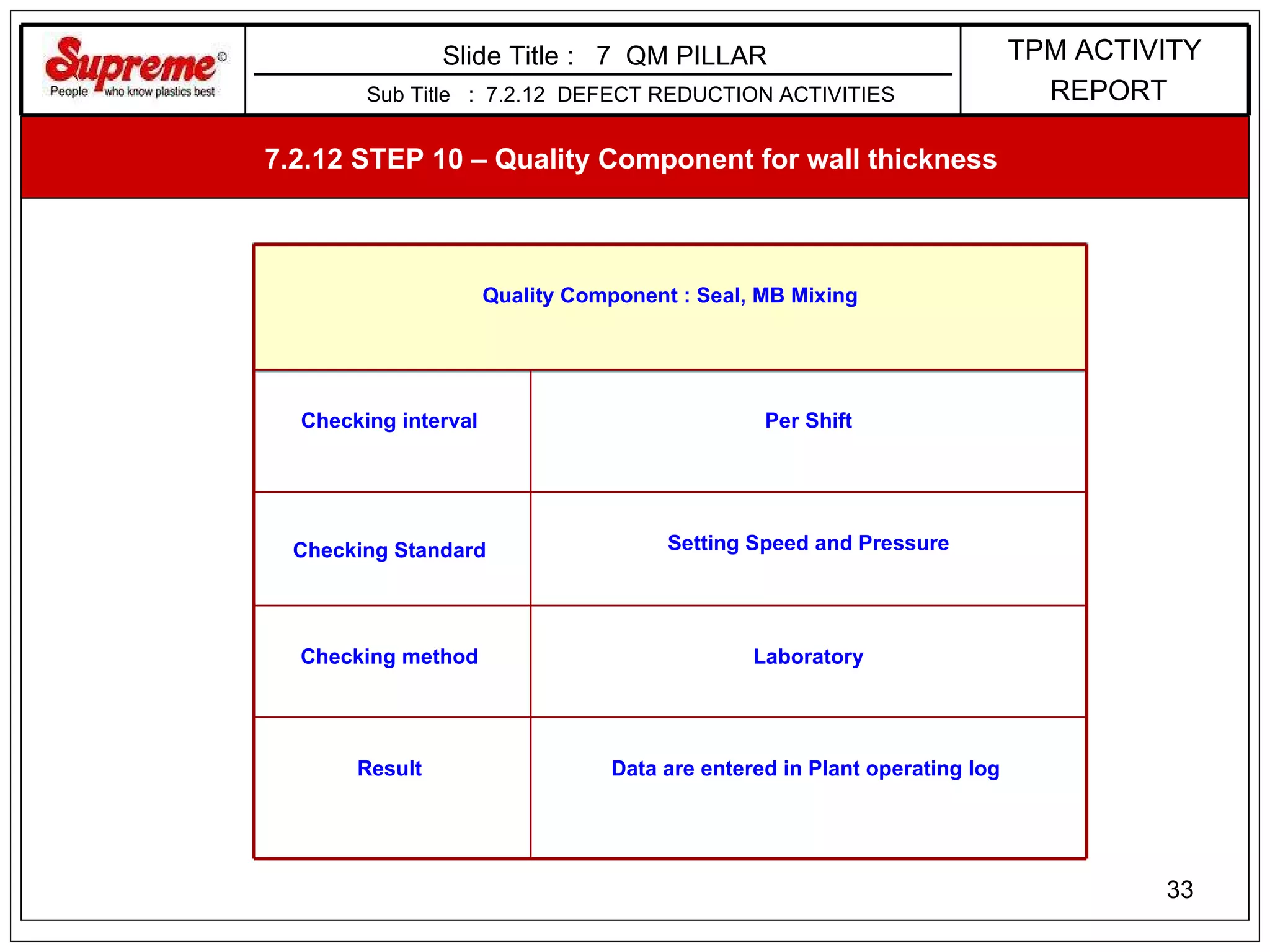

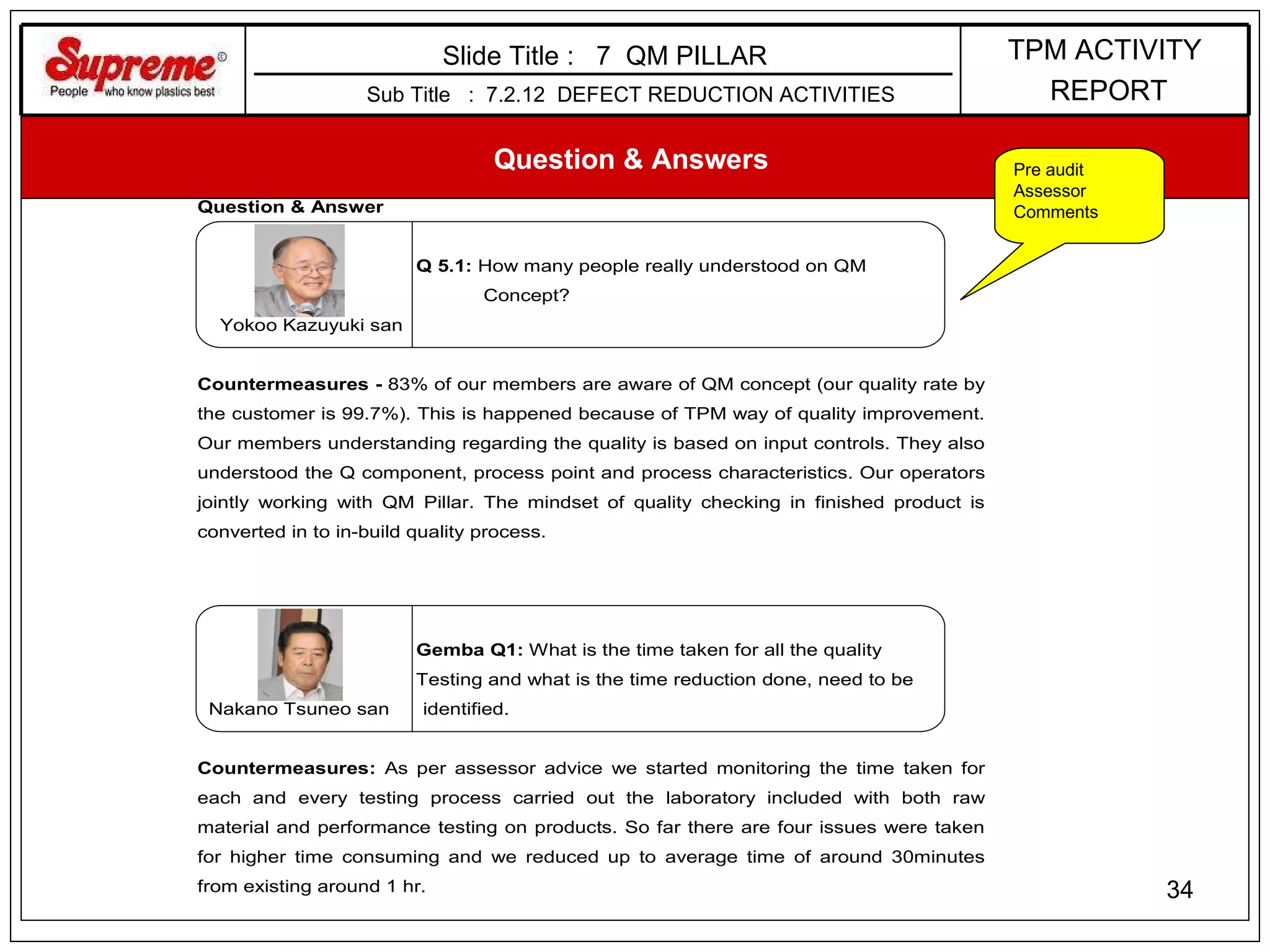

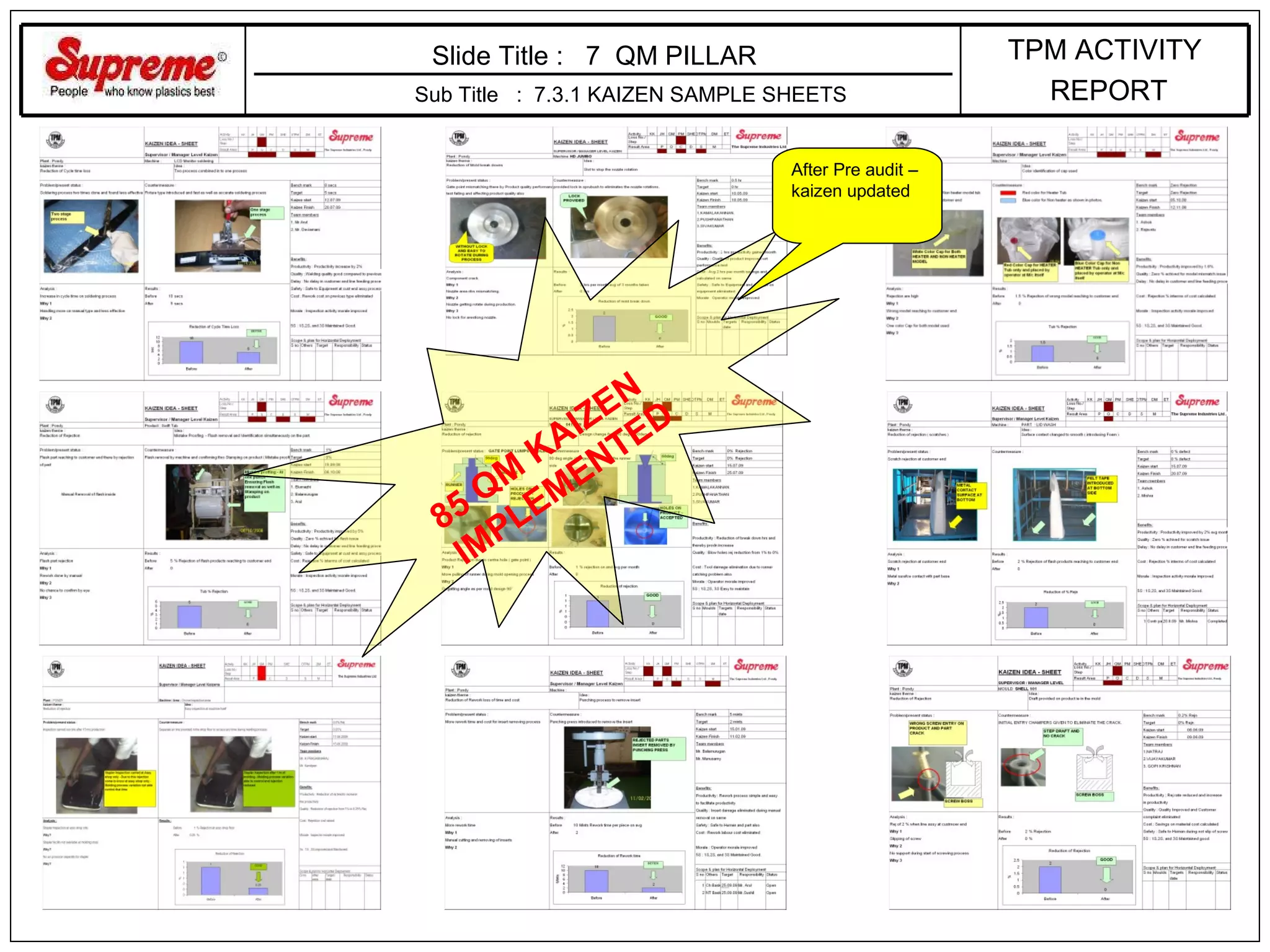

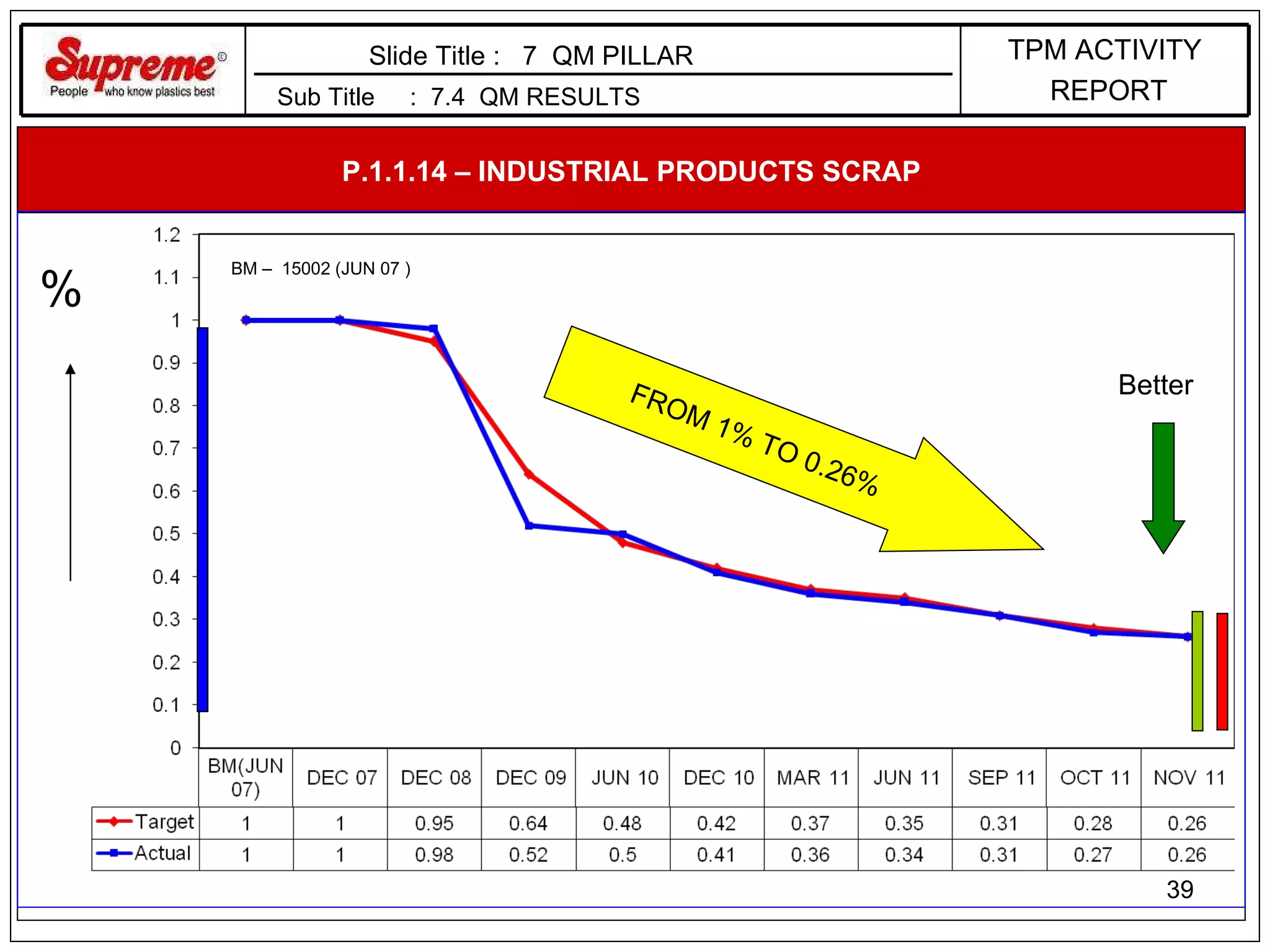

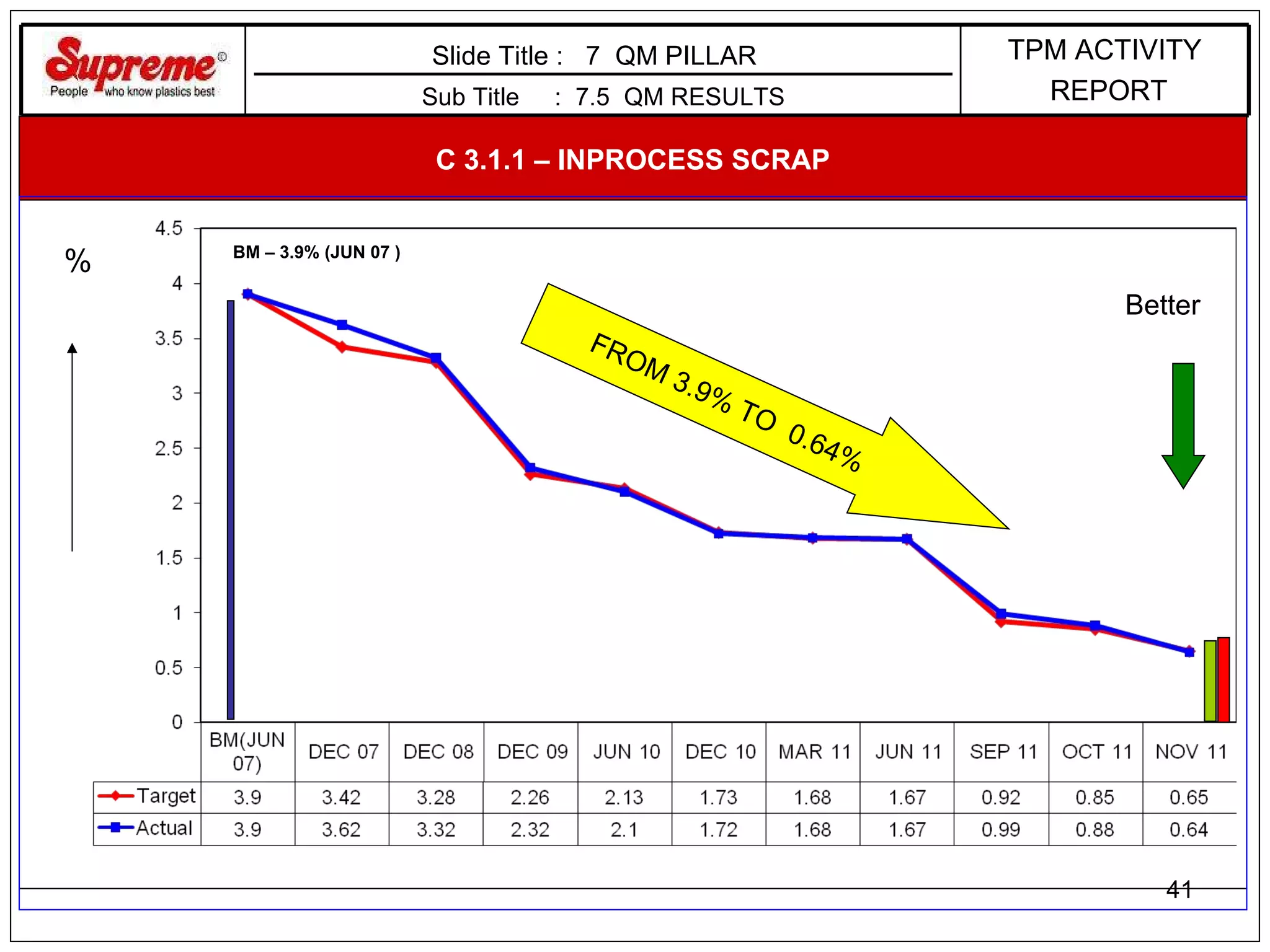

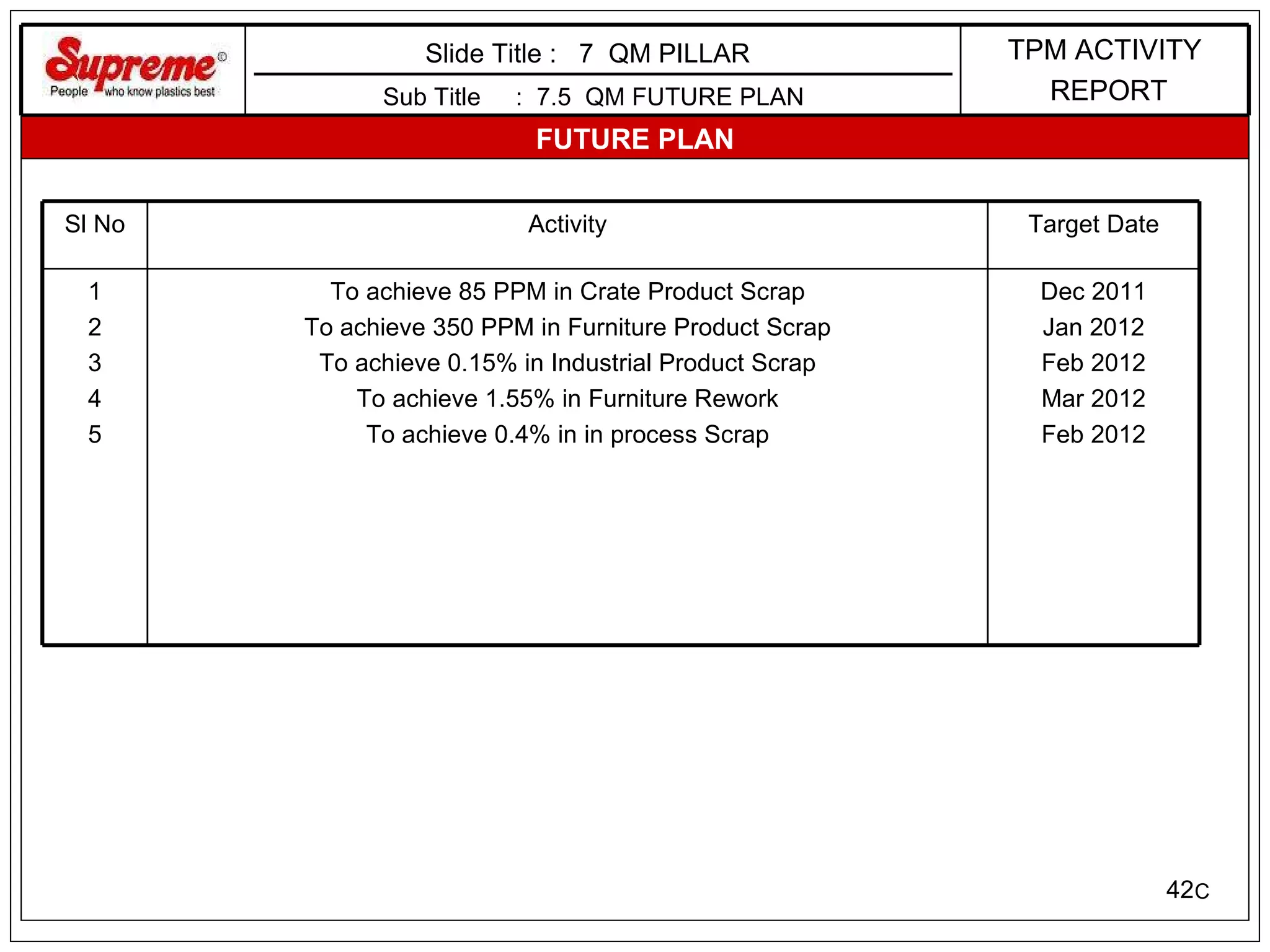

This document summarizes the quality management pillar activities at a company. It discusses the vision, goals, organization structure and targets of the quality management pillar. It then describes the quality management approach, including identifying defects, conducting analysis to determine root causes, and implementing improvements. Metrics such as KPIs and defects are analyzed over time. Future plans include continuing to refine processes and reduce defects.