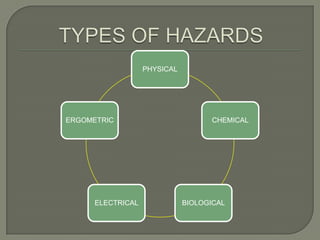

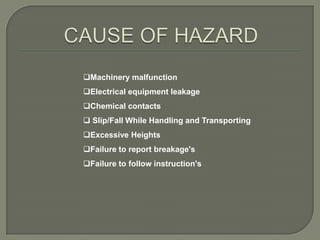

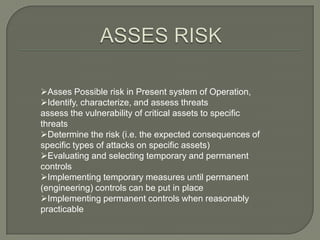

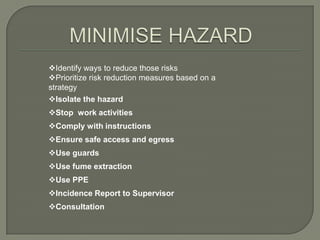

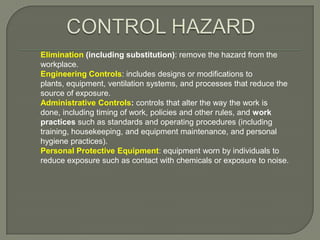

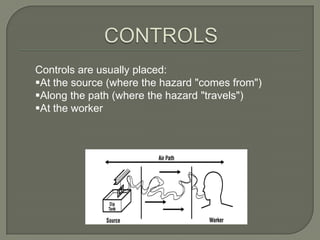

This document discusses hazard identification and risk assessment. It defines hazards as anything with potential to cause harm. A risk assessment considers likelihood and severity of hazards to determine necessary precautions. Common hazards include chemical, biological, physical, ergonomic and electrical. Hazard engineering identifies and controls hazards using specialist skills. A control program protects workers from substance exposure through monitoring and procedures. Controls include elimination, engineering, administrative controls and personal protective equipment. Effective controls assess risks, identify hazards, monitor exposure, review controls and prevent/minimize hazards.