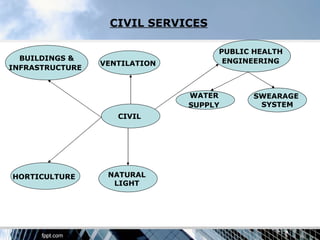

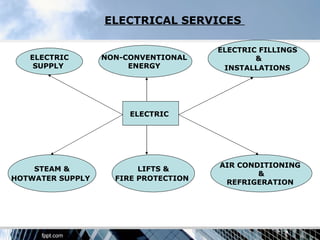

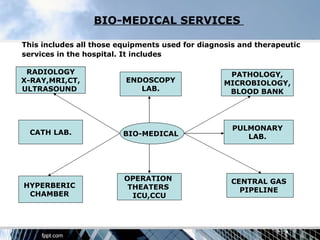

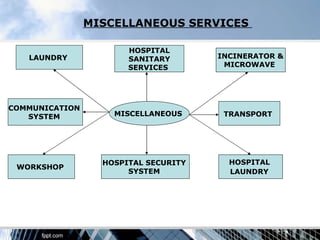

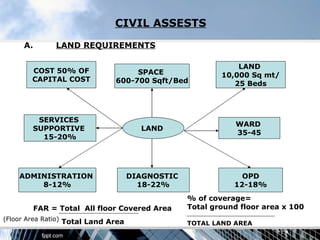

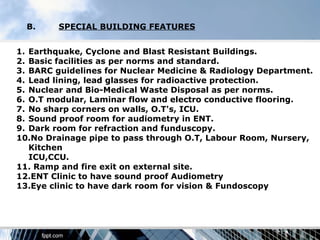

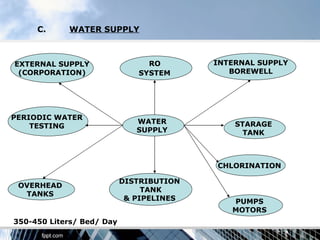

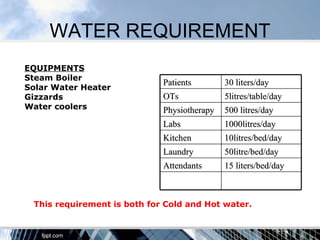

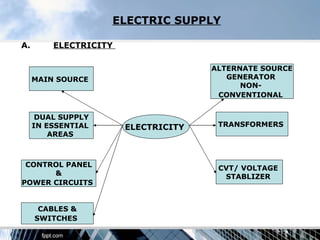

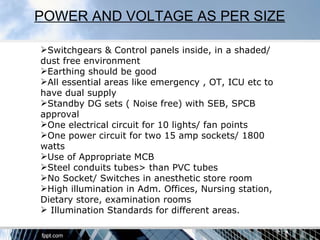

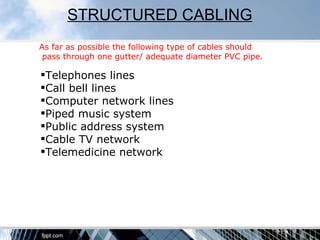

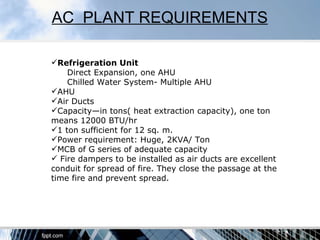

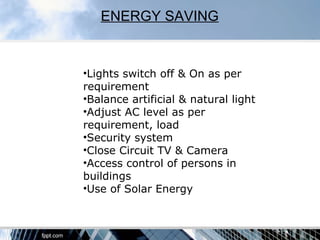

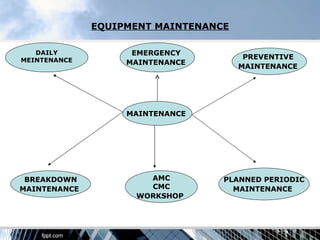

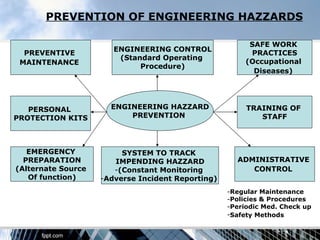

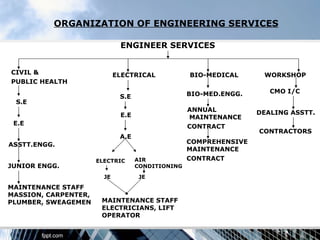

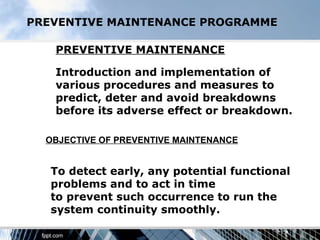

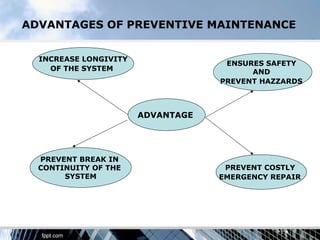

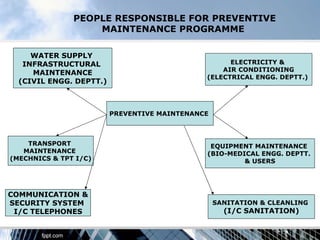

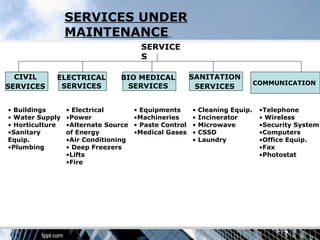

The document provides an overview of the engineering services required for a hospital. It discusses the various civil, electrical, biomedical, and other support services needed. The engineering services can be broadly classified into civil services, electrical services, biomedical services, and other miscellaneous services. It emphasizes the importance of preventive maintenance to ensure the smooth functioning of the hospital. It also outlines the organization of the engineering department and responsibilities of staff to effectively manage the various engineering services.