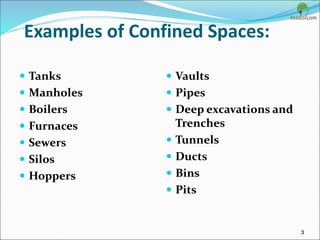

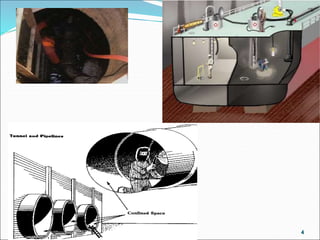

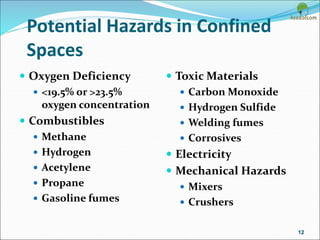

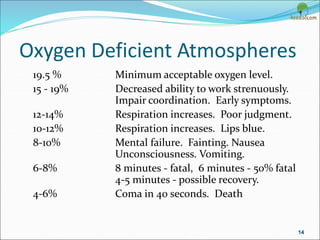

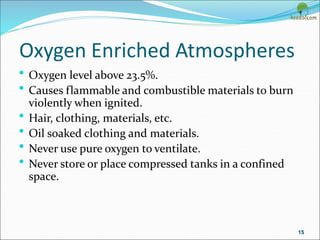

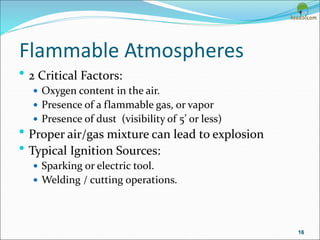

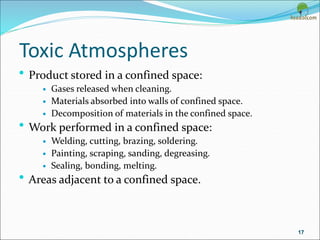

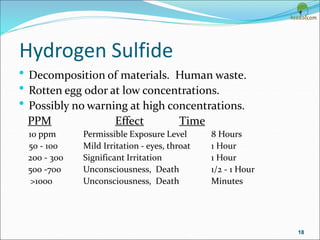

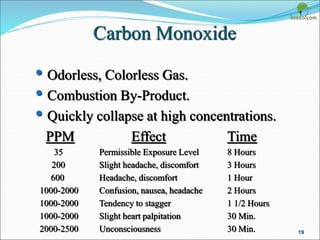

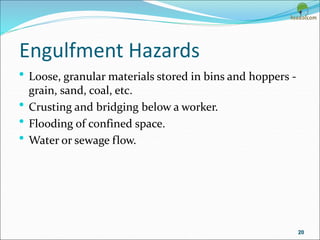

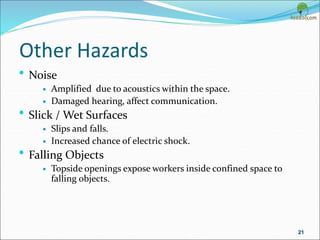

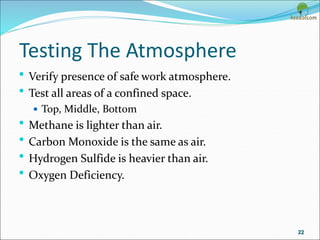

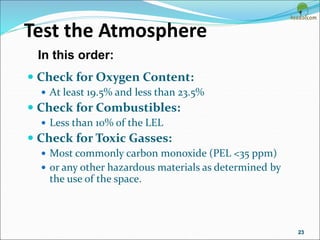

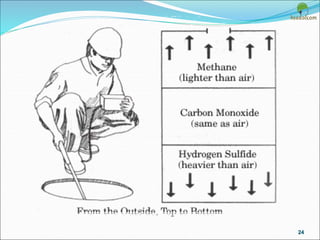

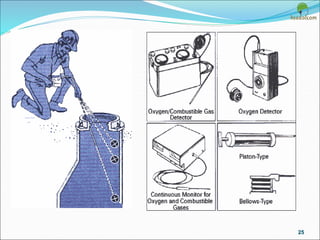

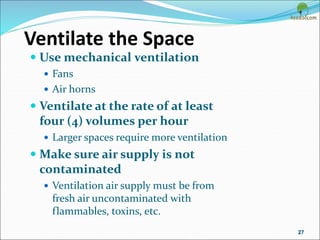

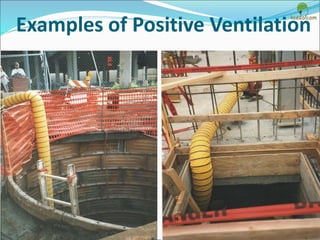

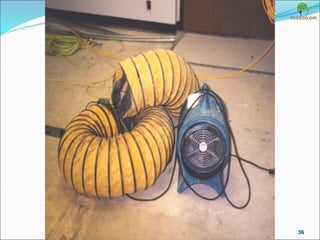

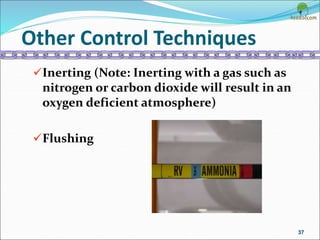

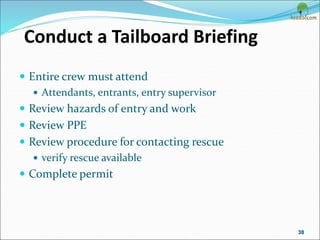

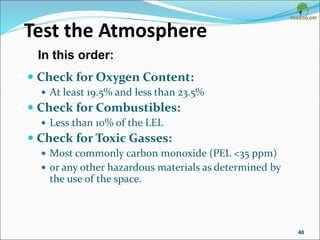

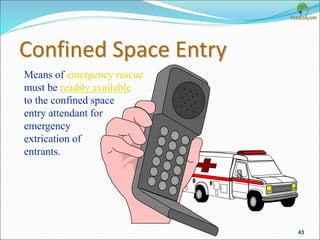

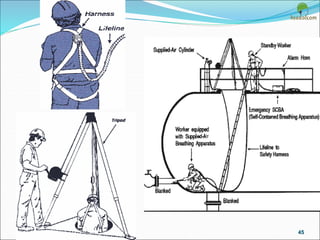

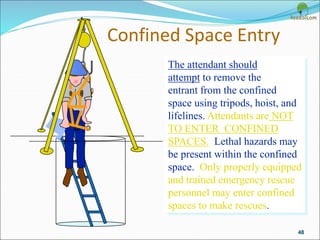

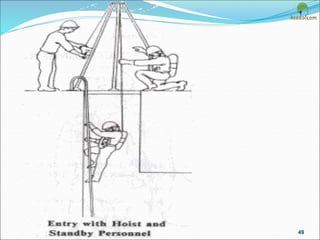

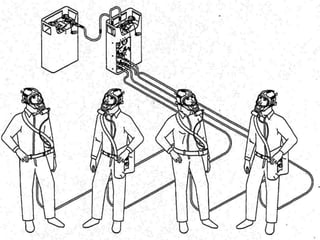

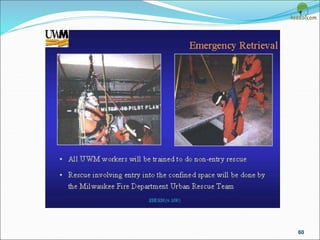

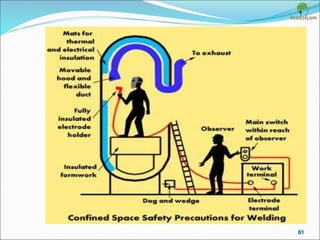

This document provides information on confined spaces and confined space entry requirements. It defines a confined space, lists examples of confined spaces, and identifies potential hazards such as oxygen deficiency, combustible gases, toxic atmospheres, and mechanical or electrical hazards. It outlines permit requirements for confined space entry including procedures for isolating, ventilating, conducting pre-entry briefings, completing permits, atmospheric testing, and duties of entrants and attendants. Rescue and emergency services are required and proper PPE and training must be provided.