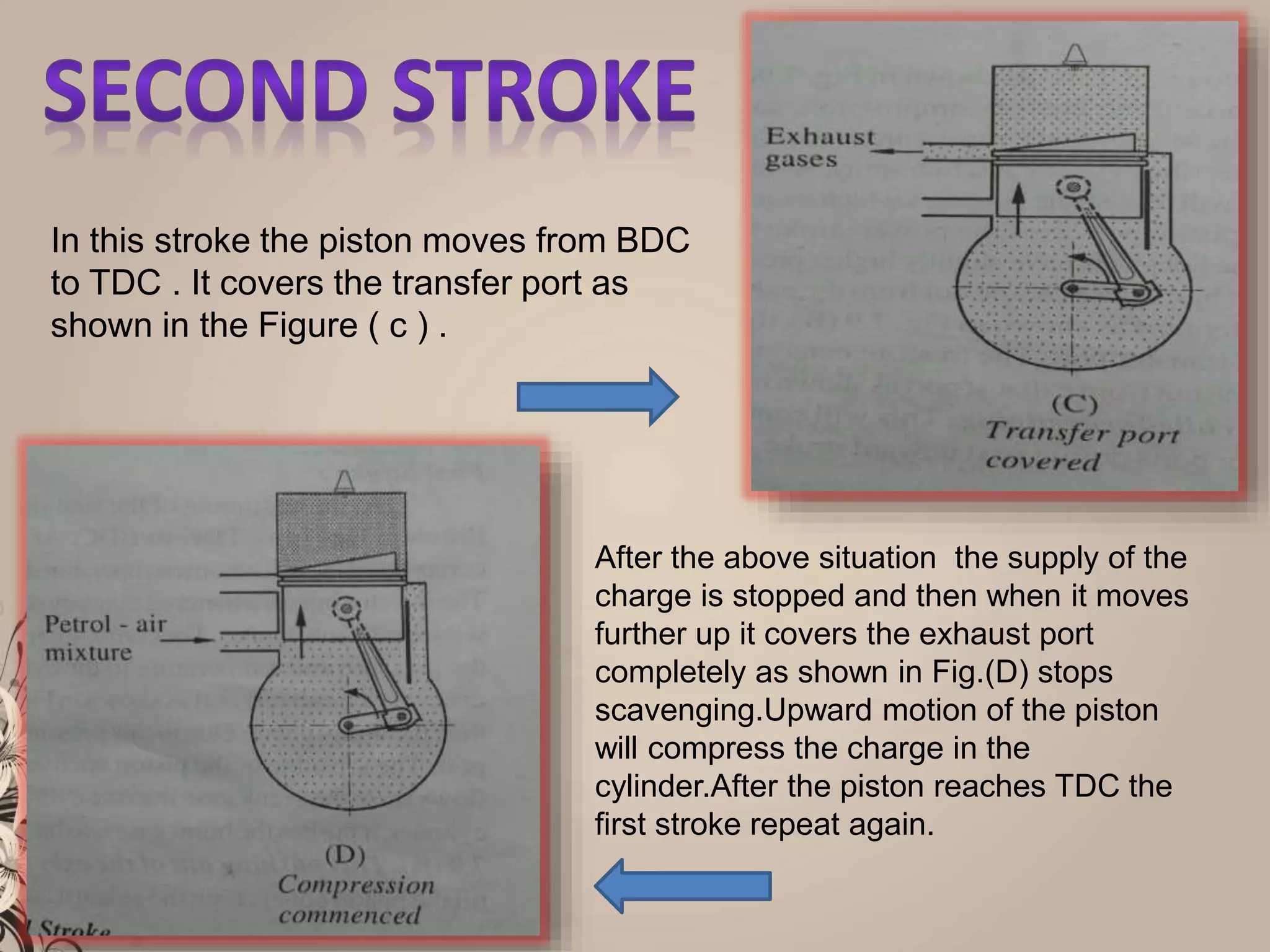

The document discusses the history and functioning of two-stroke petrol engines. It notes that the first two-stroke design was a 1878 diesel engine by Dugald Clark. It then explains the basic four steps of the two-stroke engine cycle: 1) intake of petrol-air mixture through the inlet port into the crankcase; 2) compression of the charge in the crankcase and transfer to the cylinder; 3) ignition and power stroke; 4) exhaust of burnt gases through the exhaust port. The cycle is completed within one revolution of the crankshaft.