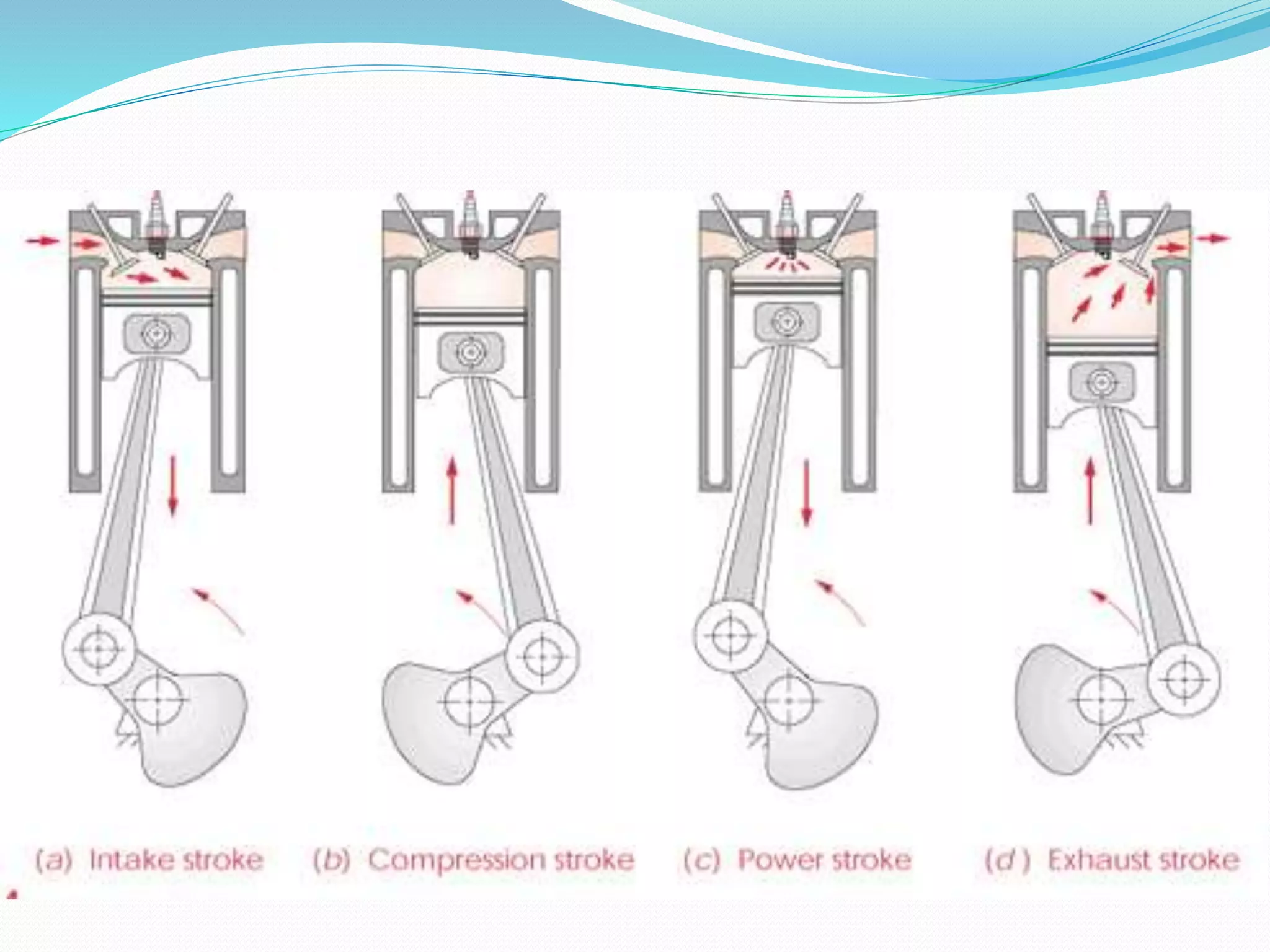

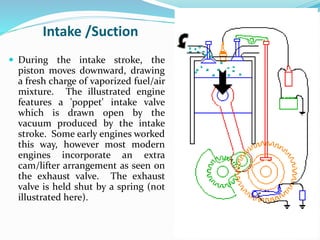

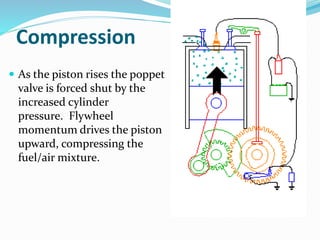

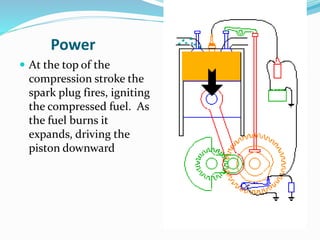

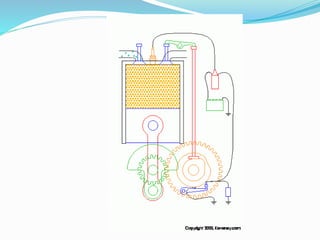

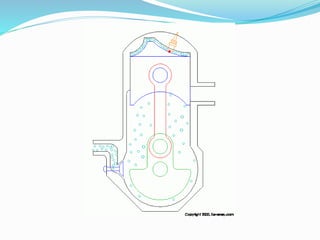

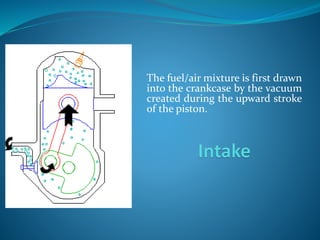

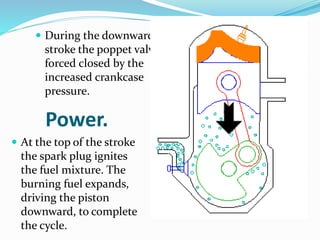

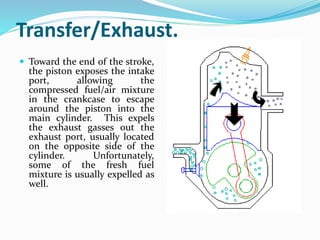

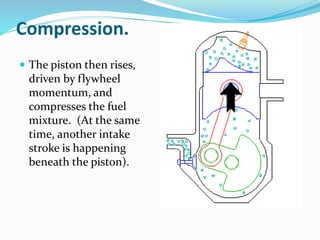

The document describes the four stages of the combustion cycle in a 4-stroke engine: intake, compression, power, and exhaust. During intake, the piston moves down and draws in the fuel-air mixture through the open intake valve. In compression, the valve closes and the piston compresses the mixture. At top-dead-center in power, the spark plug ignites the compressed mixture, pushing the piston down. During exhaust, the exhaust valve opens and the piston pushes out the exhaust gases.