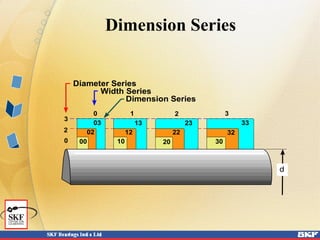

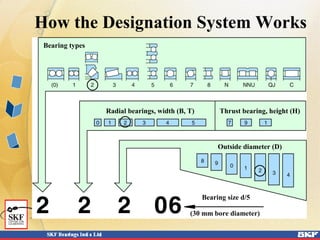

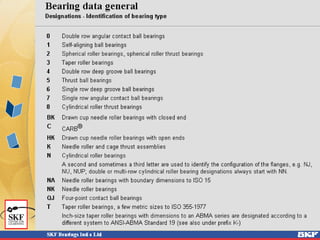

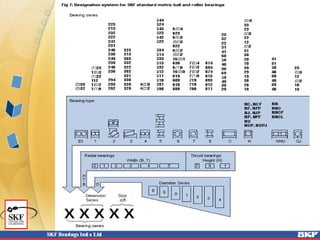

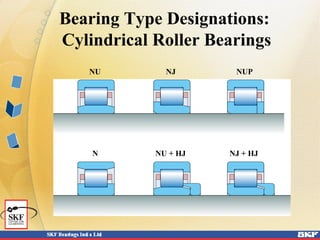

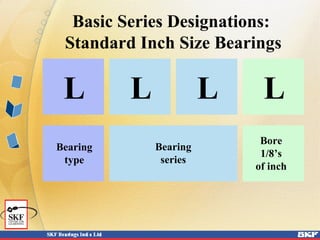

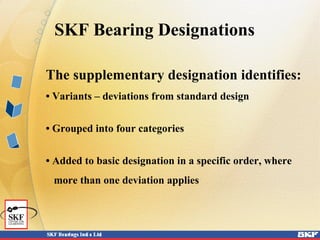

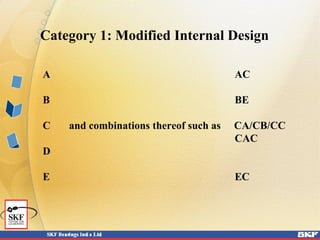

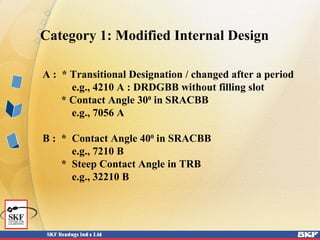

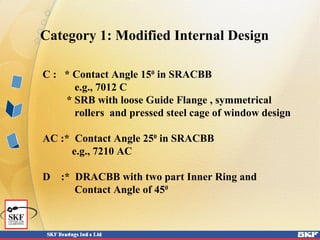

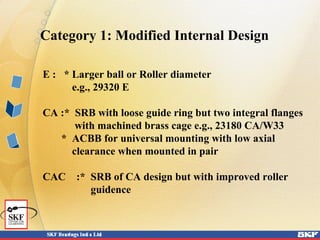

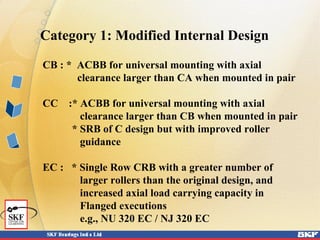

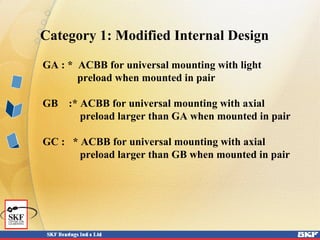

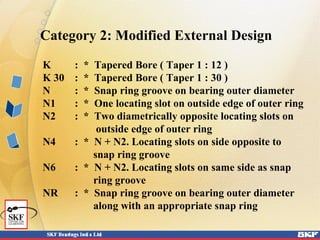

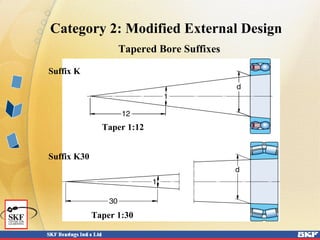

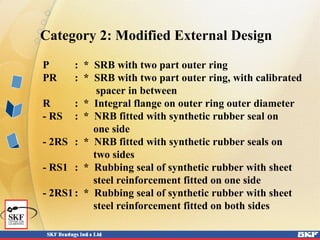

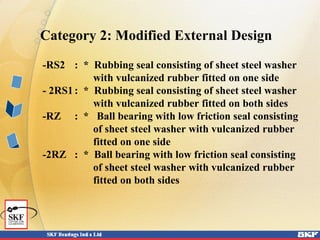

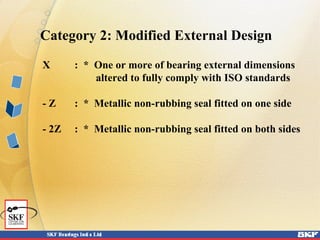

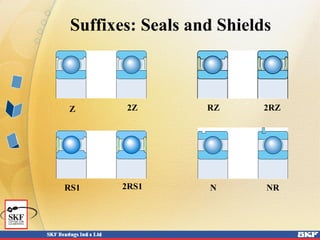

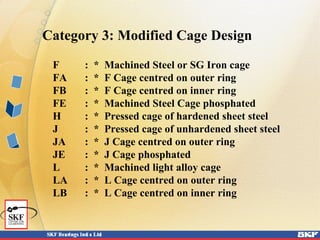

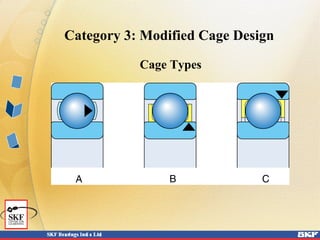

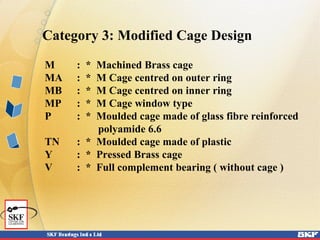

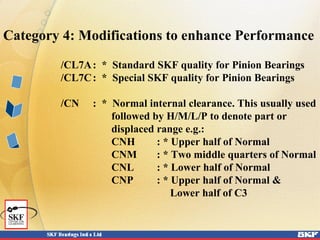

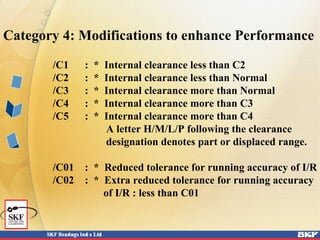

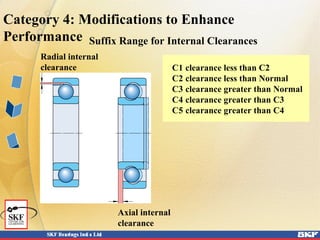

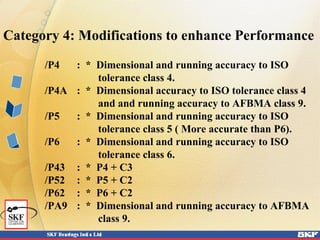

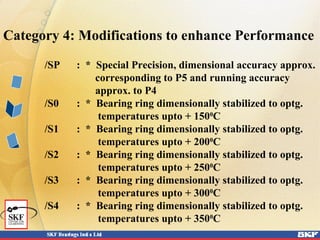

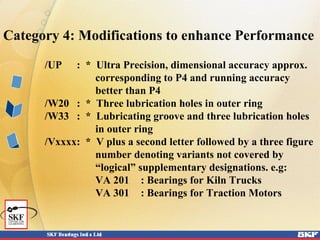

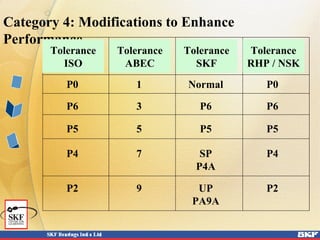

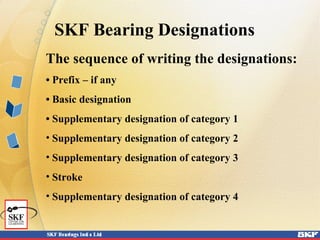

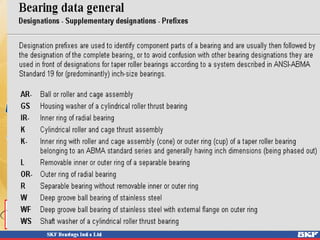

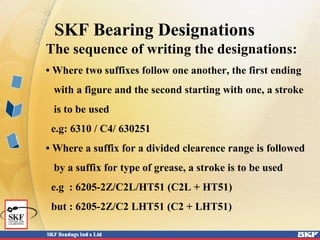

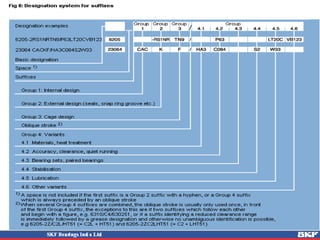

Bearing designations provide information about the bearing type, size, and any supplementary details. The basic designation indicates the product type, standard design, and size. Supplementary designations specify alternative designs, bearing components, and special types. Designations are broken into categories including internal design, external design, cage design, and performance enhancements. Together, the basic and supplementary designations precisely identify bearing characteristics.