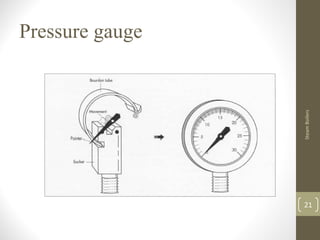

This document discusses different types of steam boilers. It begins by defining a steam boiler as a closed vessel made of steel that transfers heat from fuel combustion to water to generate steam. It then discusses various ways boilers can be classified, including by tube content, pressure, circulation type, use, axis position, and fuel type. Three specific boiler types are described in detail - the Cochran, Babcock & Wilcox, and Lancashire boilers. Key characteristics, construction details, working principles, and advantages/disadvantages are provided for each. Finally, common boiler mountings and accessories like pressure gauges, fusible plugs, and feed pumps are outlined.