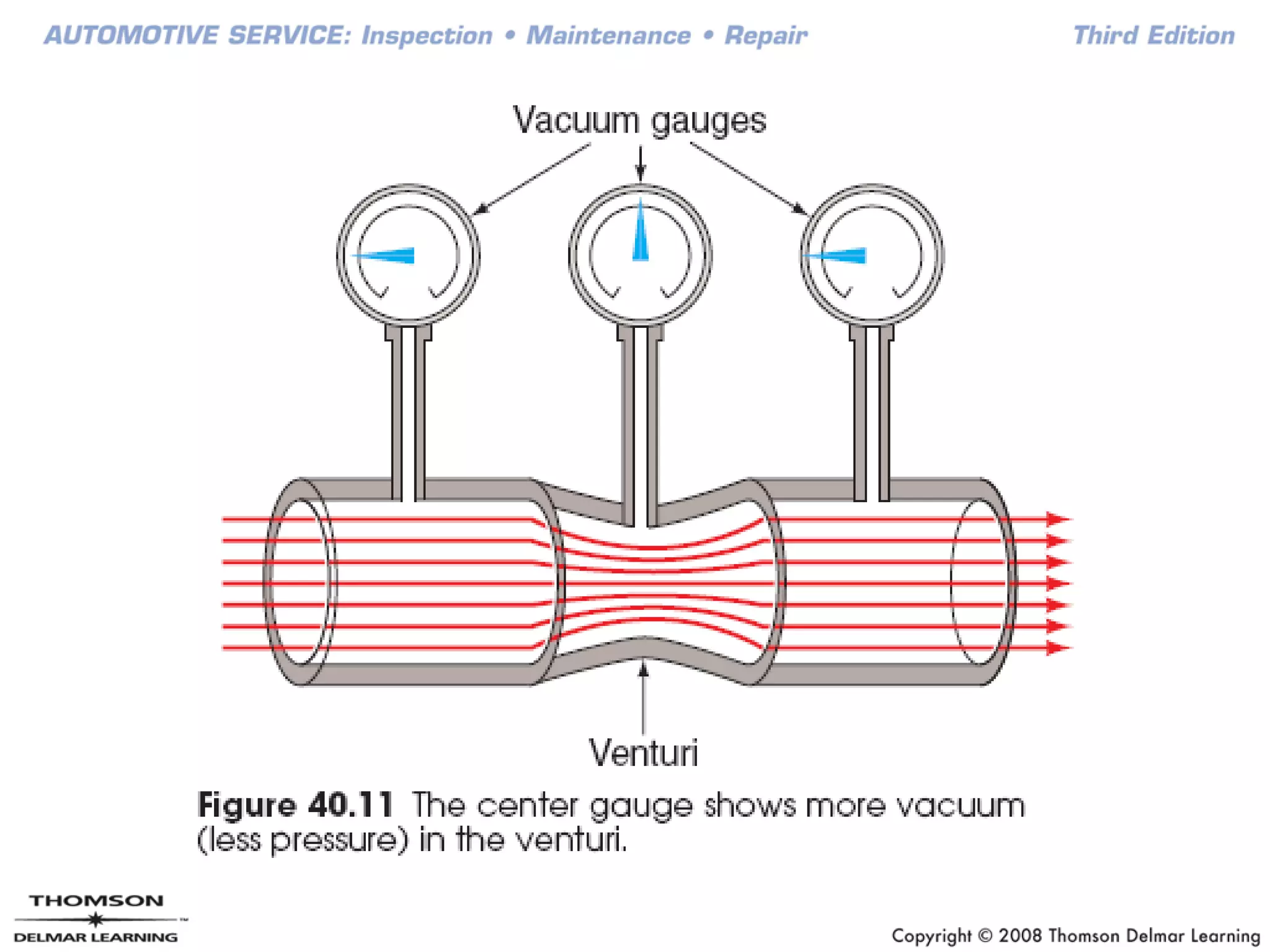

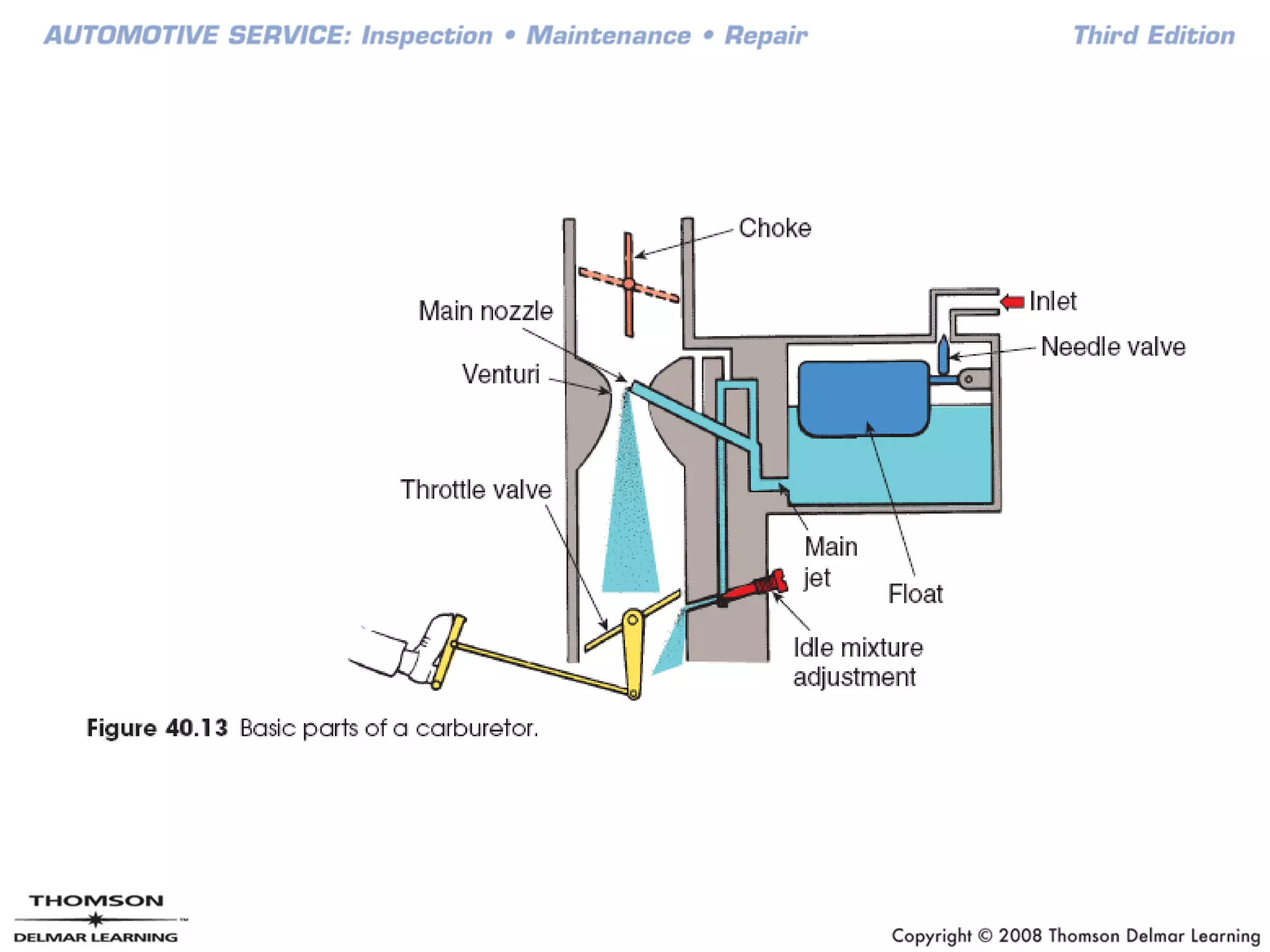

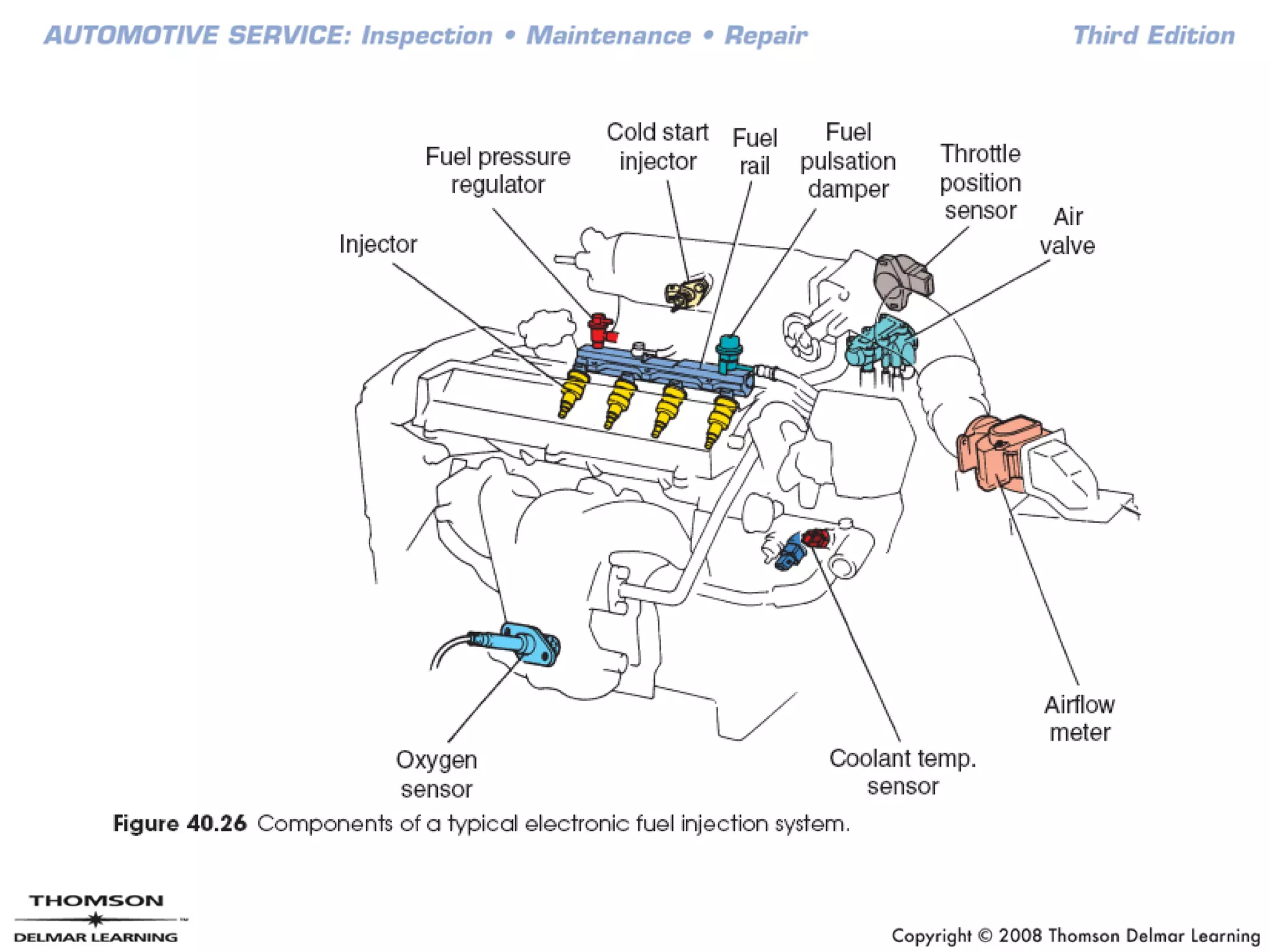

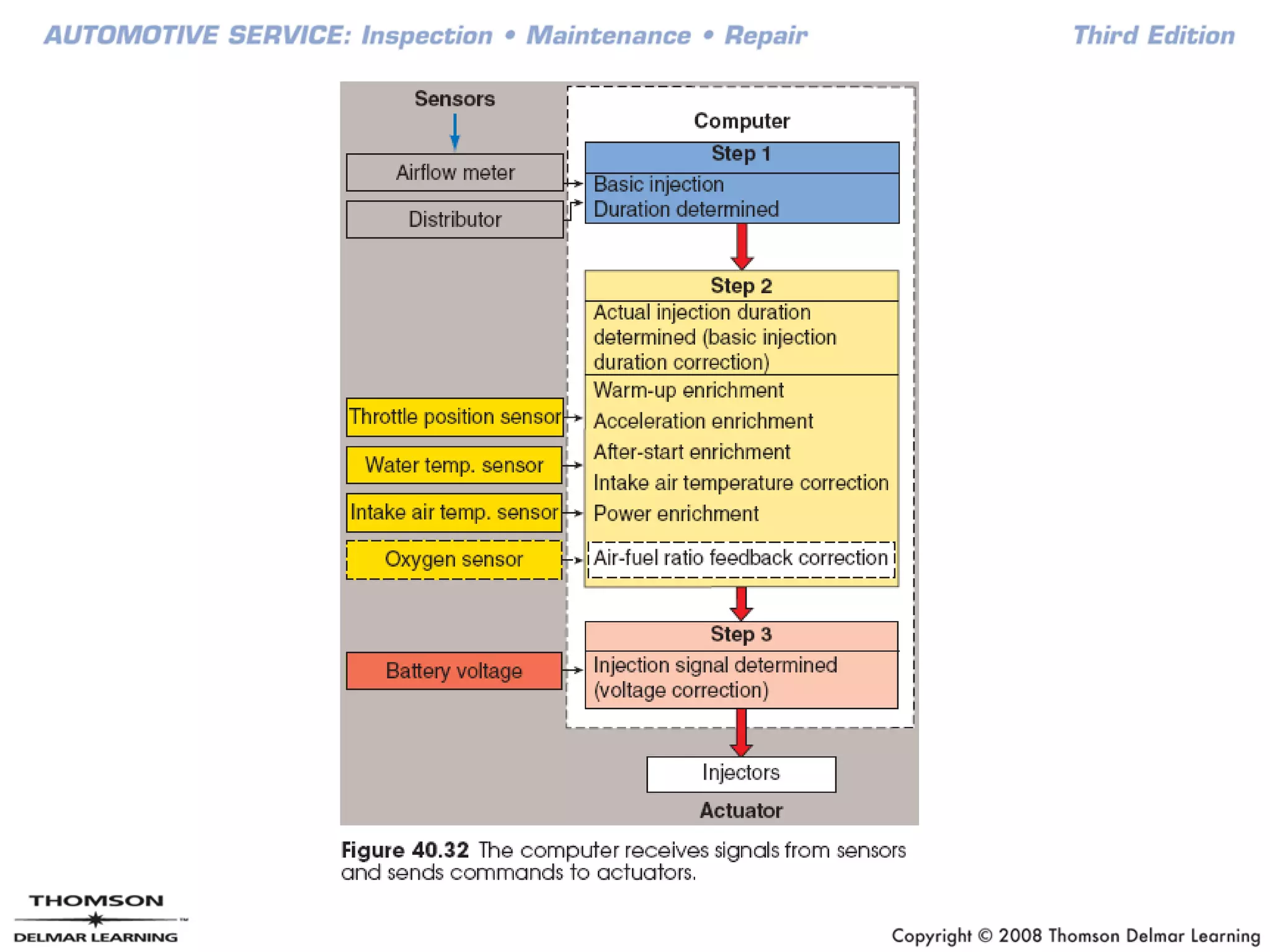

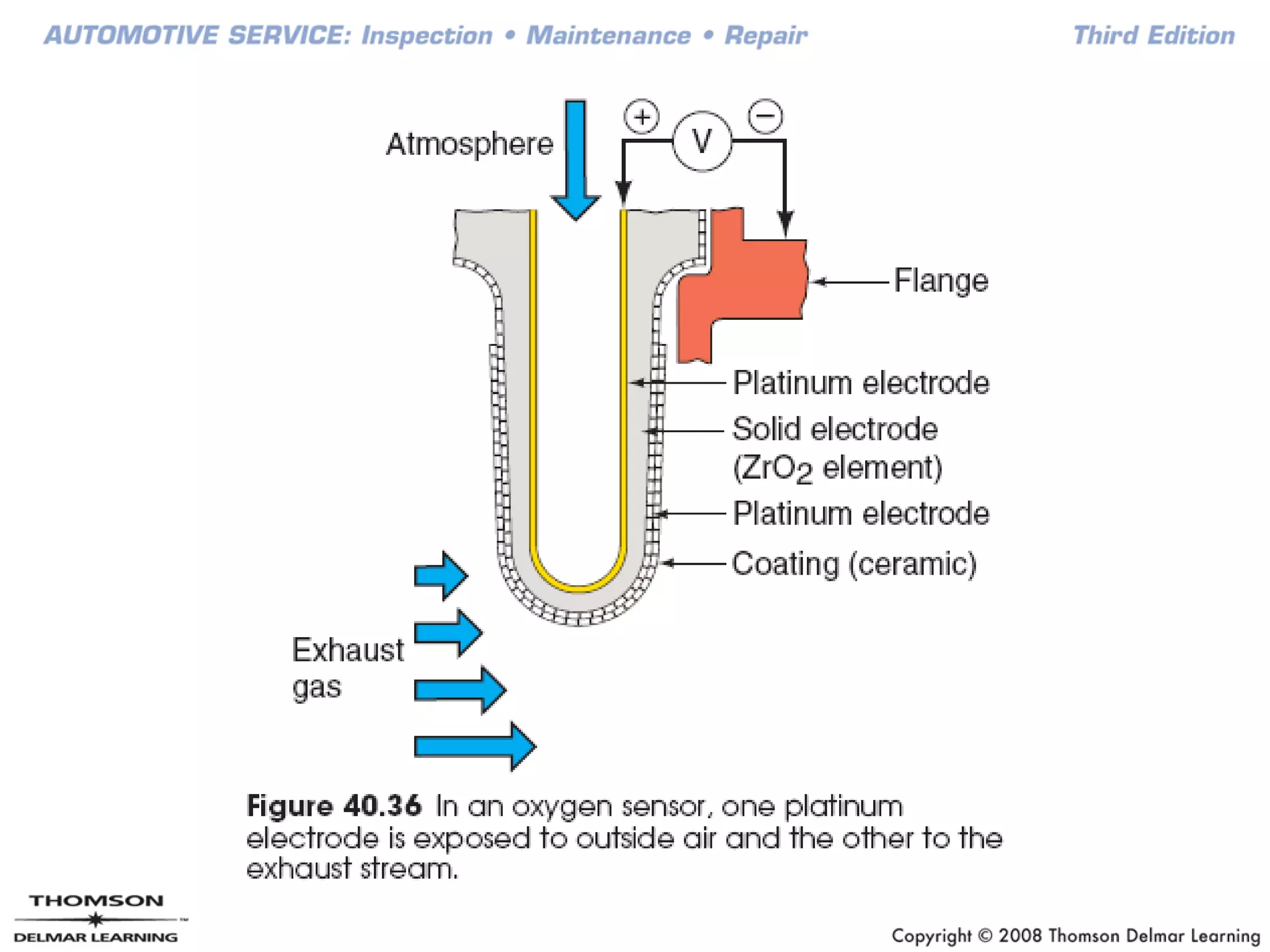

This document provides an overview of fuel systems, including the main components and how they work. It compares carbureted and fuel injected systems, describing the different types of fuel injection. Electronic fuel injection uses sensors, actuators, and a computer to precisely meter fuel delivery. The computer receives feedback from oxygen sensors to continuously adjust the air-fuel ratio for optimal performance and emissions.