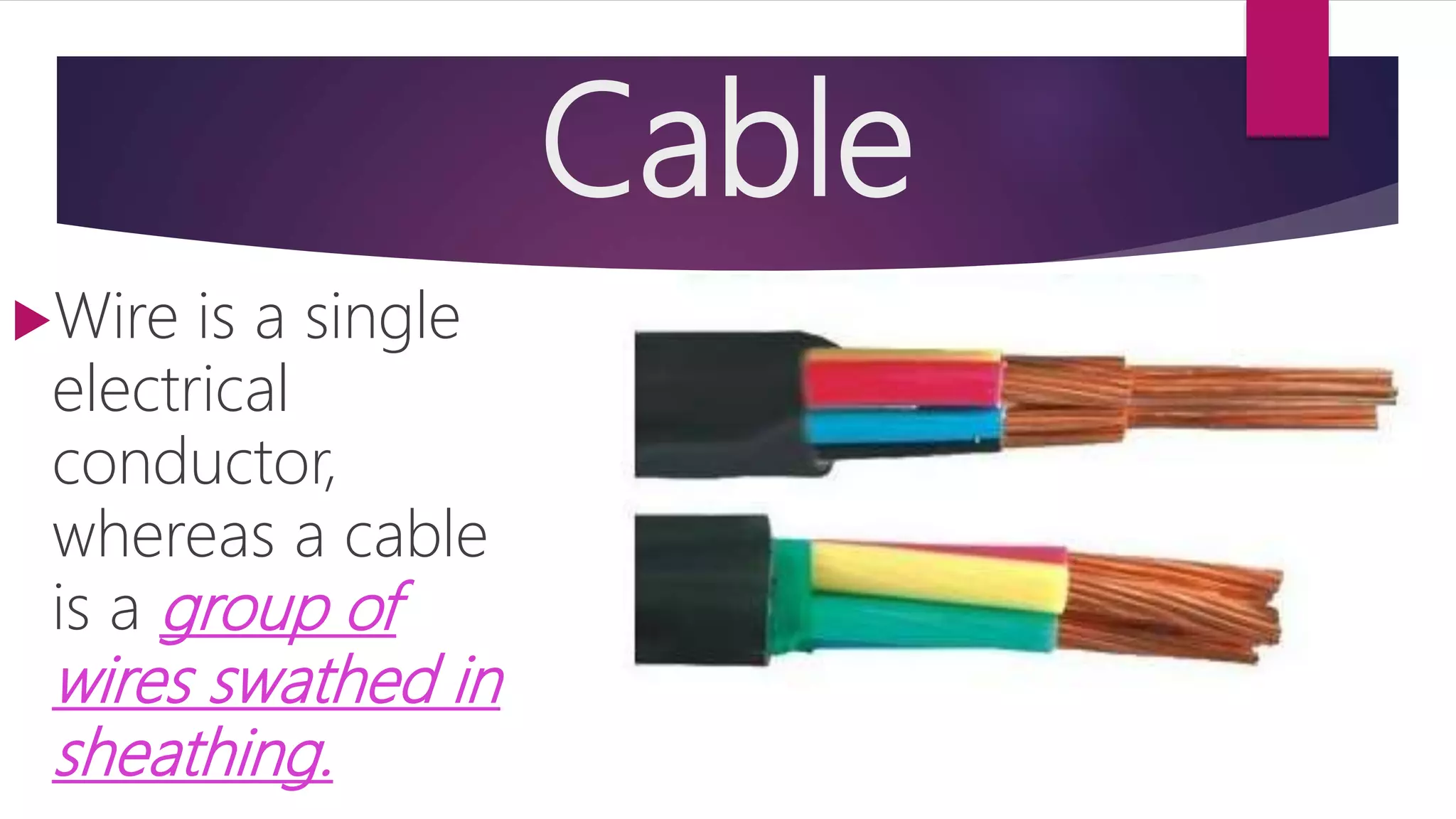

This document provides information about electrical installation and maintenance. It discusses key figures in the history of electricity such as Benjamin Franklin, Thomas Edison, and Nikola Tesla. It also covers topics like types of electric current and circuits, components of electrical systems like wires and cables, and how to perform splices and joints. Classification of wires, cables, circuits and raceways are described along with diagrams to illustrate concepts.