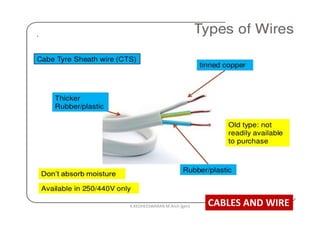

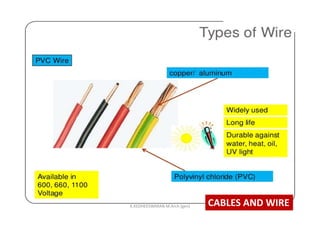

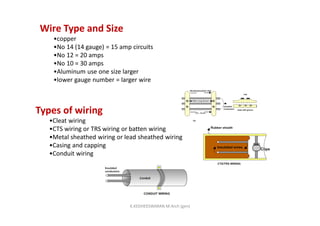

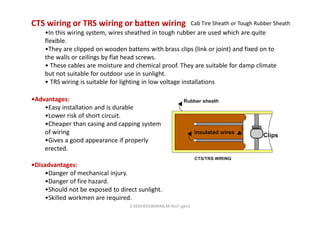

1. The document discusses different types of electrical wires and cables used in building services, including PVC, TRS, and flexible wires.

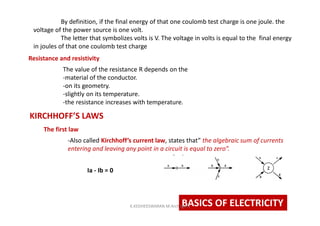

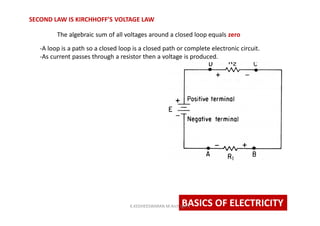

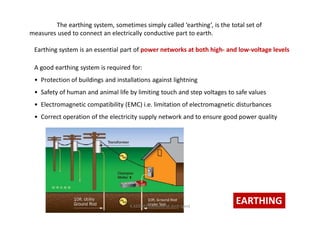

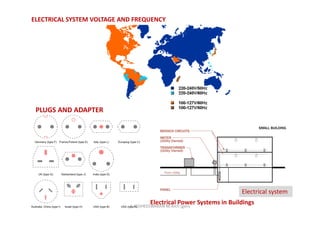

2. It also covers basics of electricity, including Ohm's Law, Kirchhoff's Laws, and different types of earthing systems used in buildings and industrial installations.

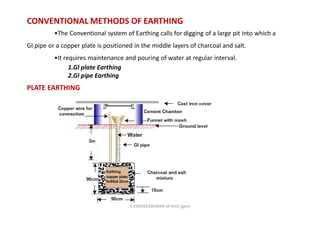

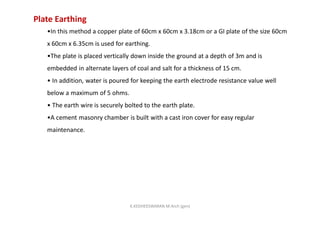

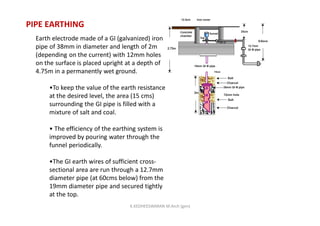

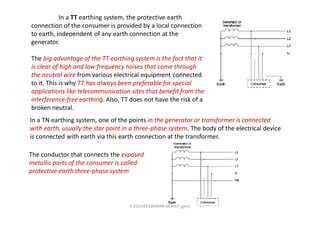

3. Types of earthing systems discussed are conventional earthing using plates and pipes, as well as TN, TT, and IT systems. Electrical and instrument earthing systems are also compared.