This document provides information on installing electrical metallic tubing (EMT), including:

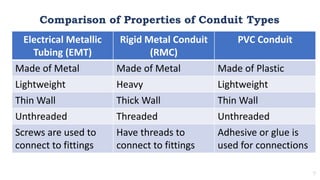

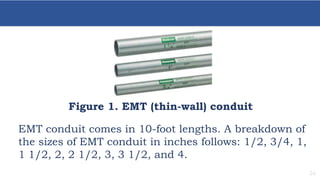

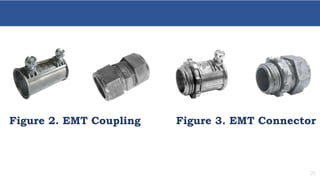

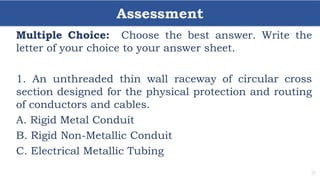

1. It defines EMT as an unthreaded, thin-walled metal raceway for routing electrical conductors and cables, and identifies its uses according to Philippine Electrical Code (PEC) provisions.

2. The learning objectives are to identify EMT, prepare EMT according to PEC, and understand good workmanship and code compliance.

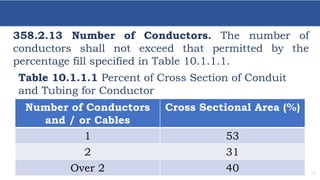

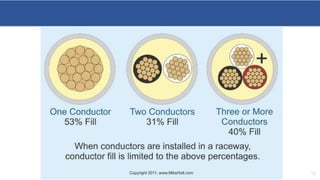

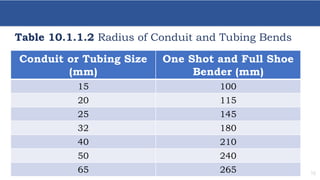

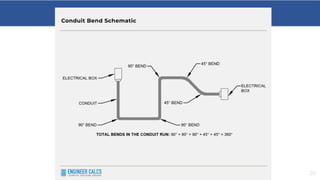

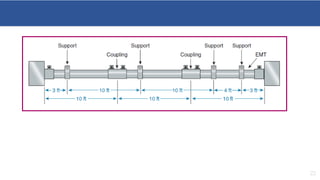

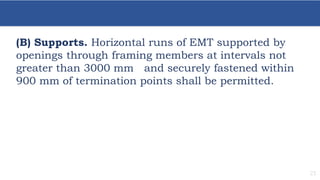

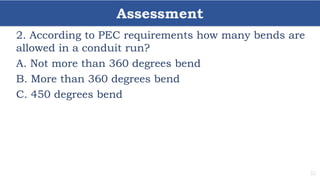

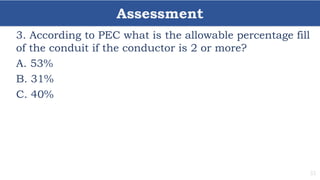

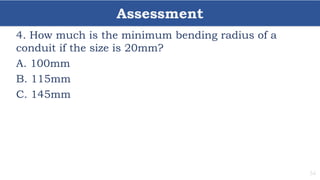

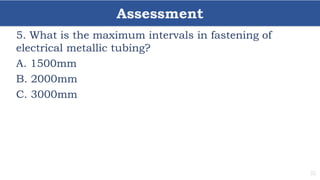

3. The document gives specifications for EMT from the PEC, including minimum and maximum sizes, bending radii, supporting intervals, and number of bends allowed between pull points.