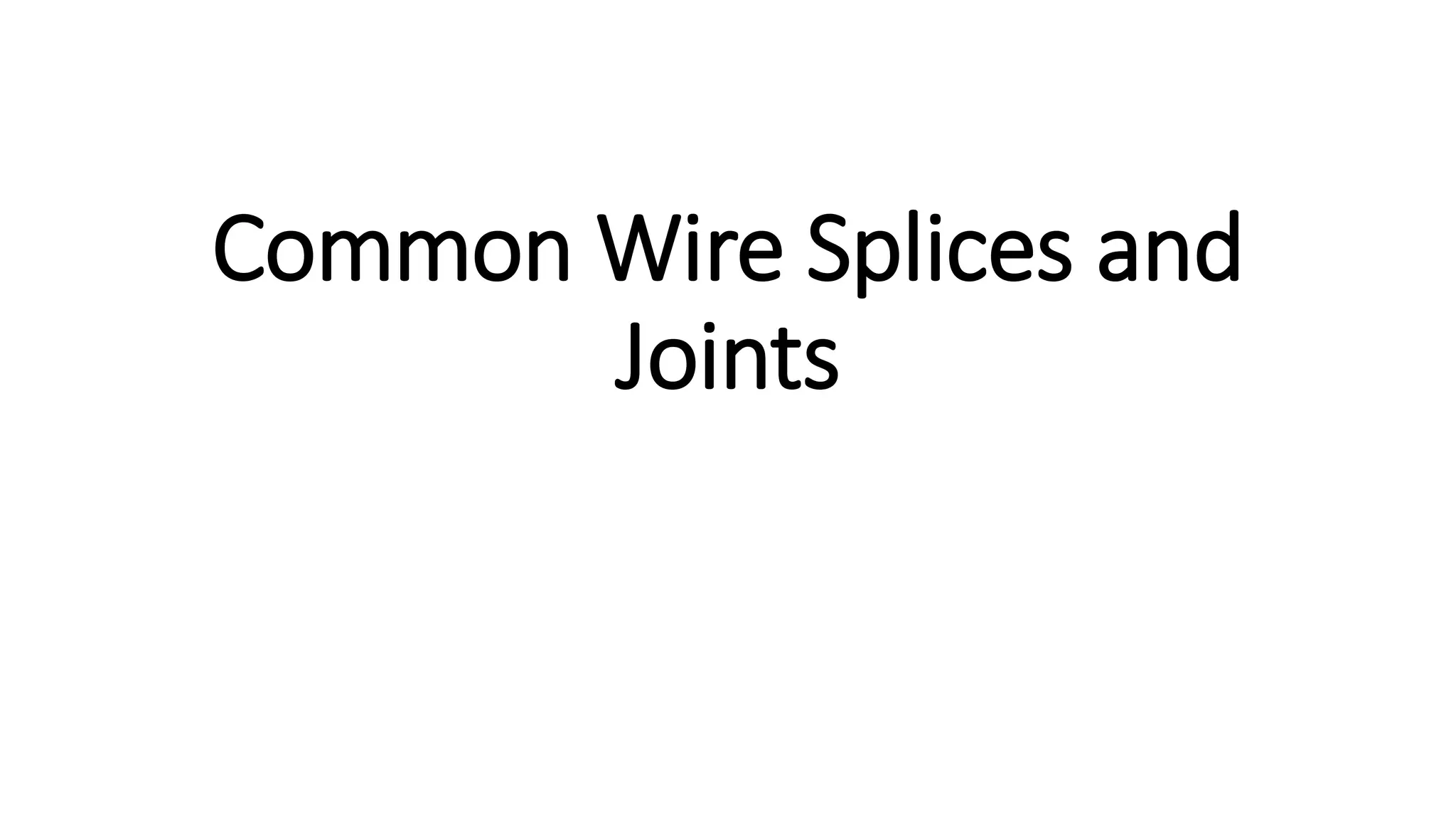

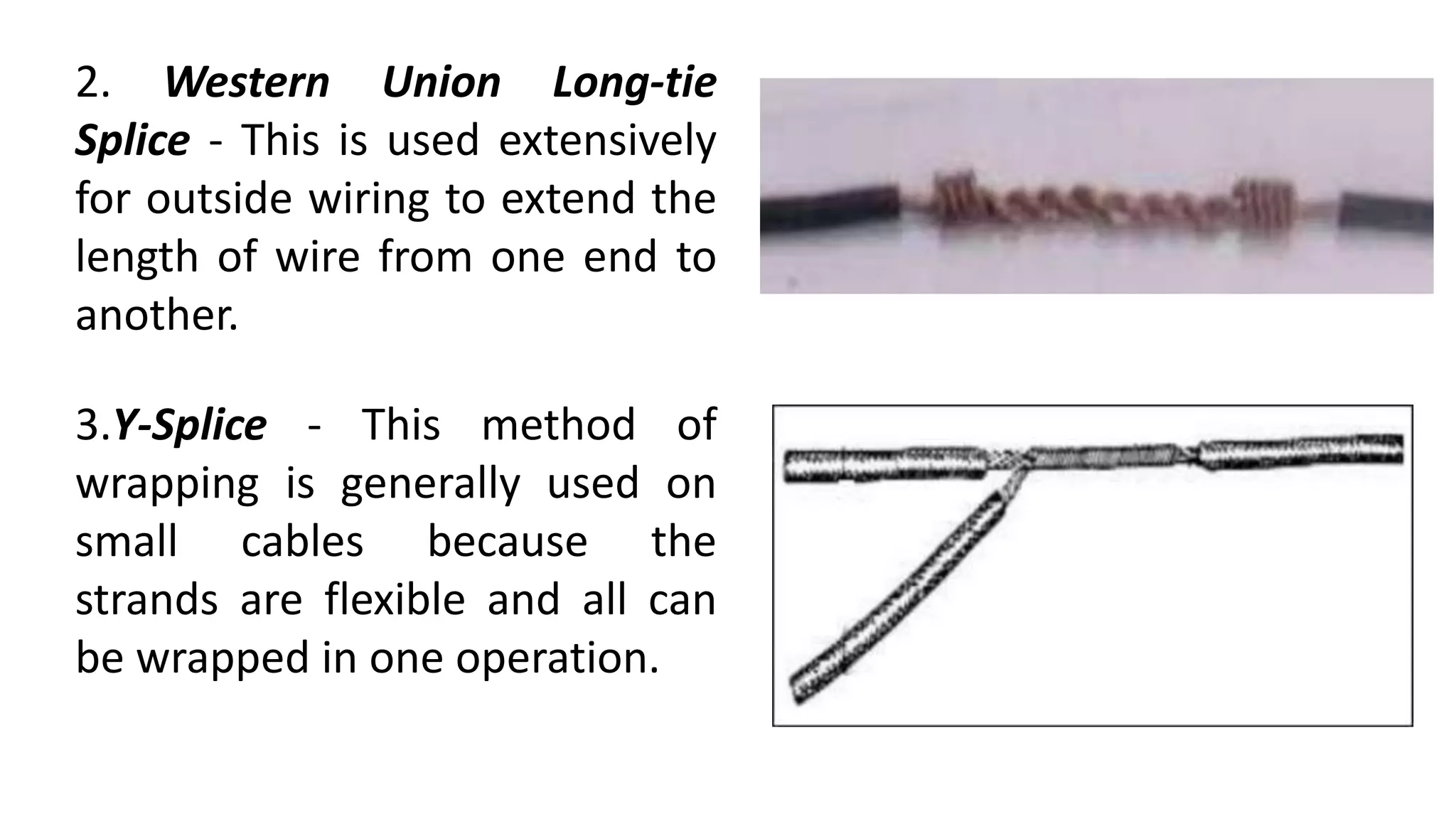

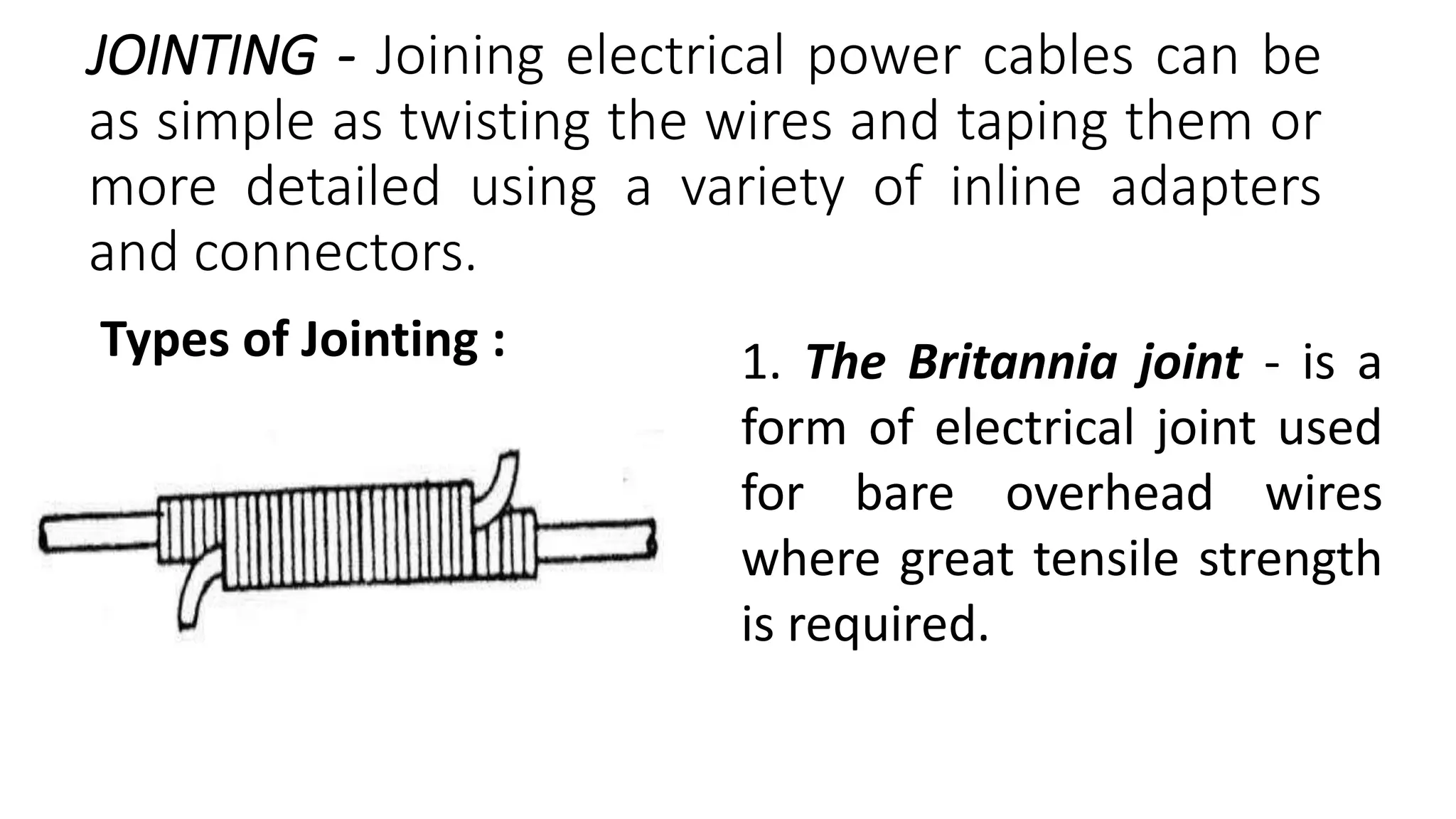

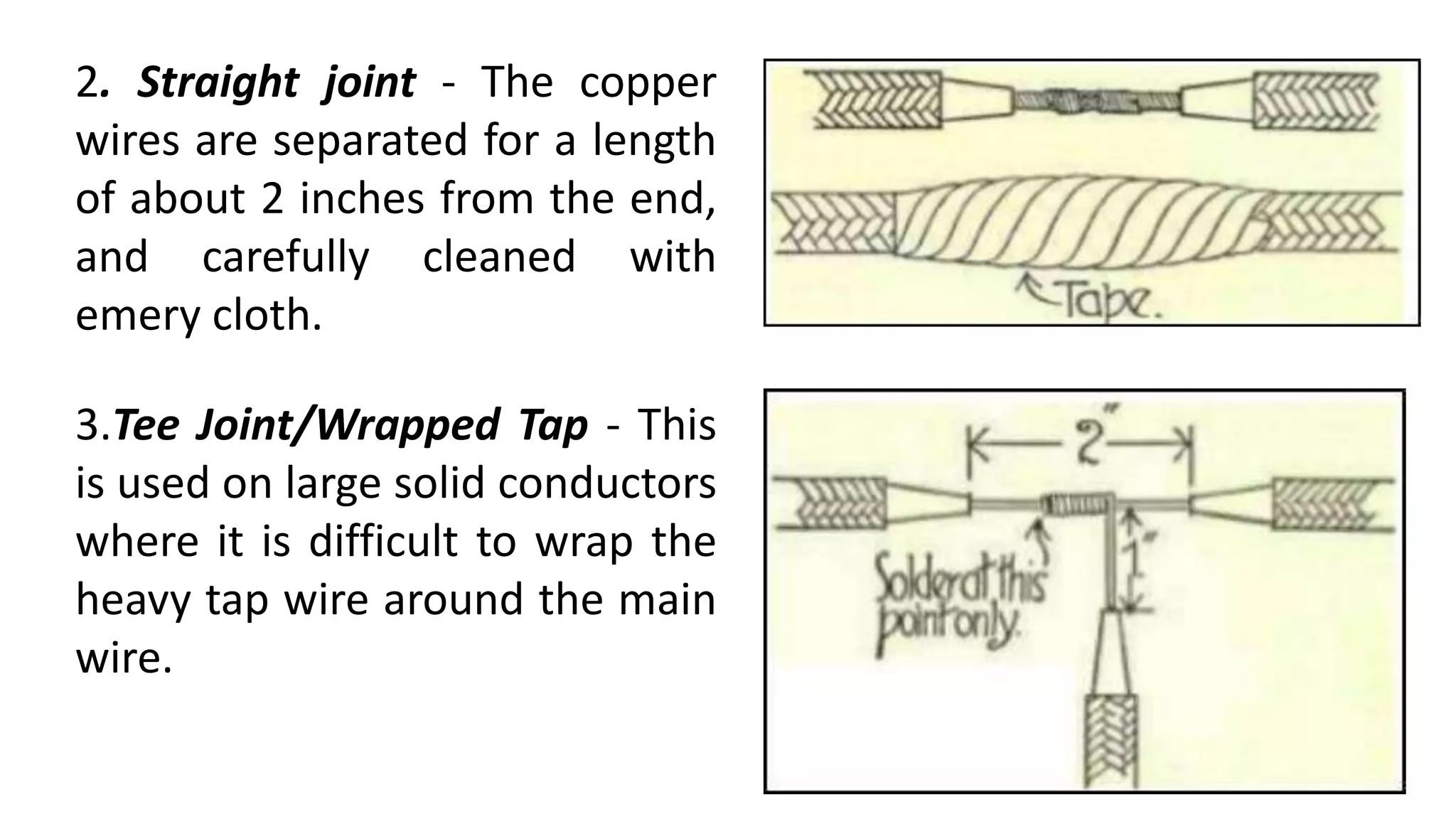

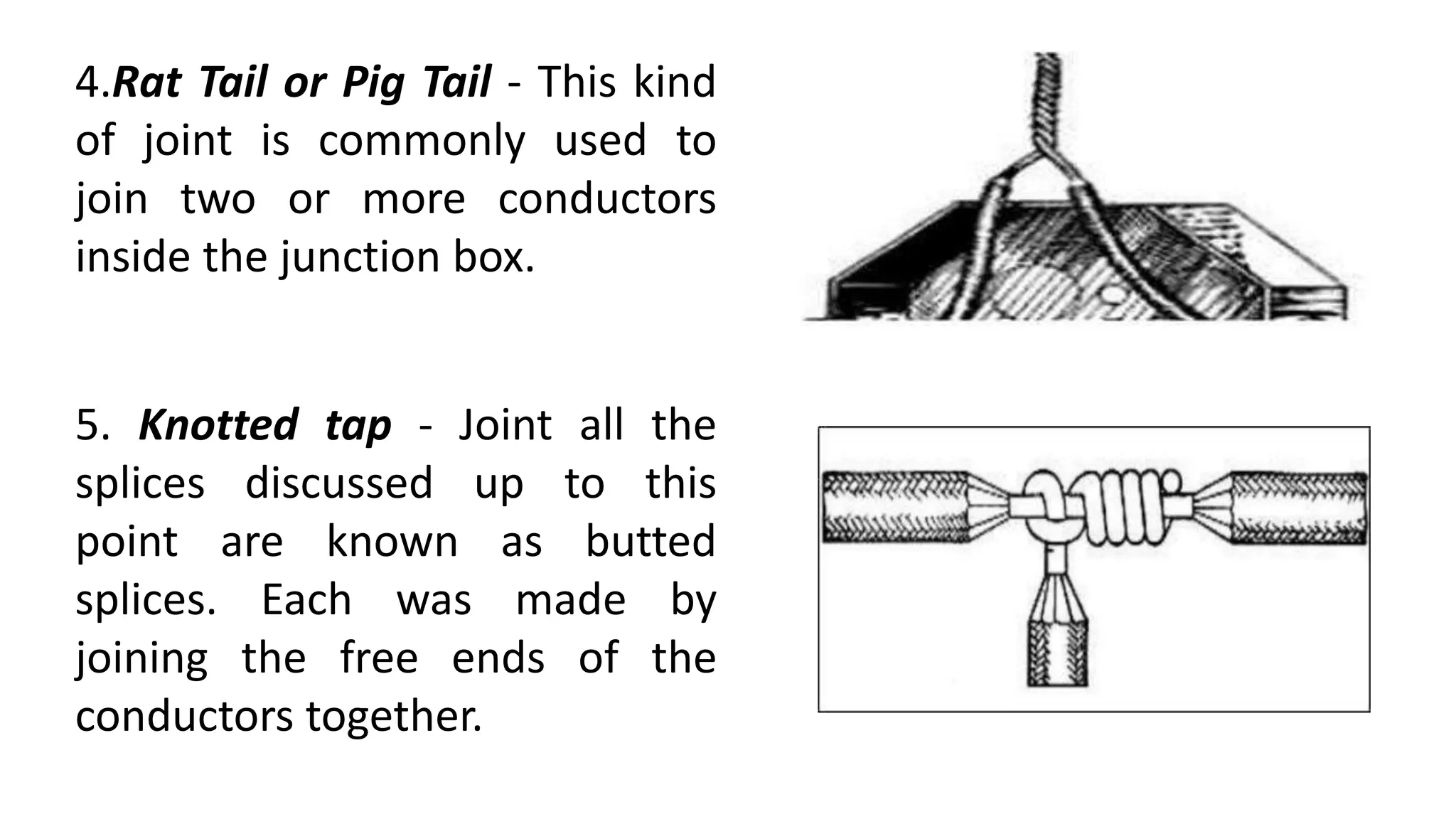

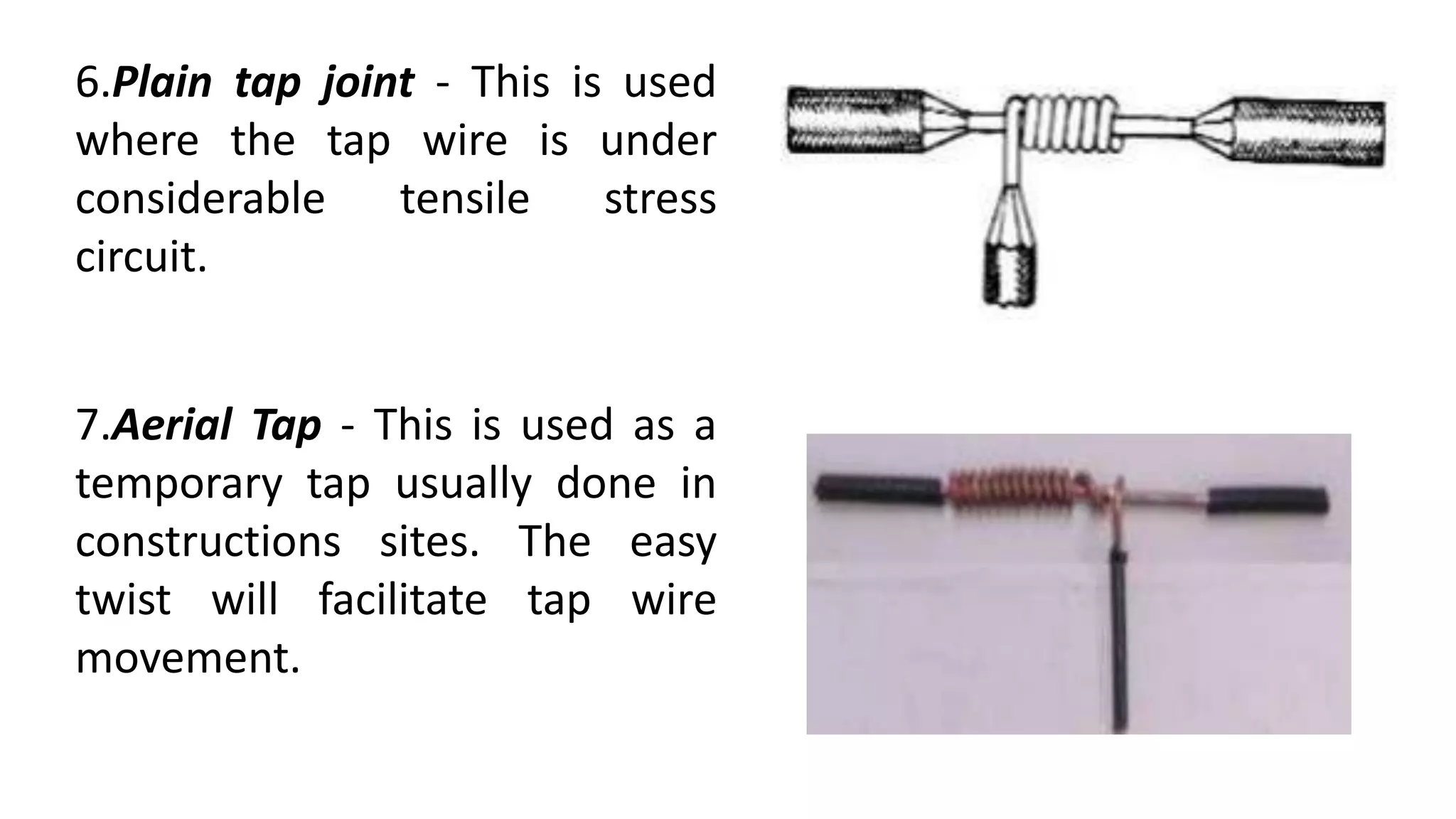

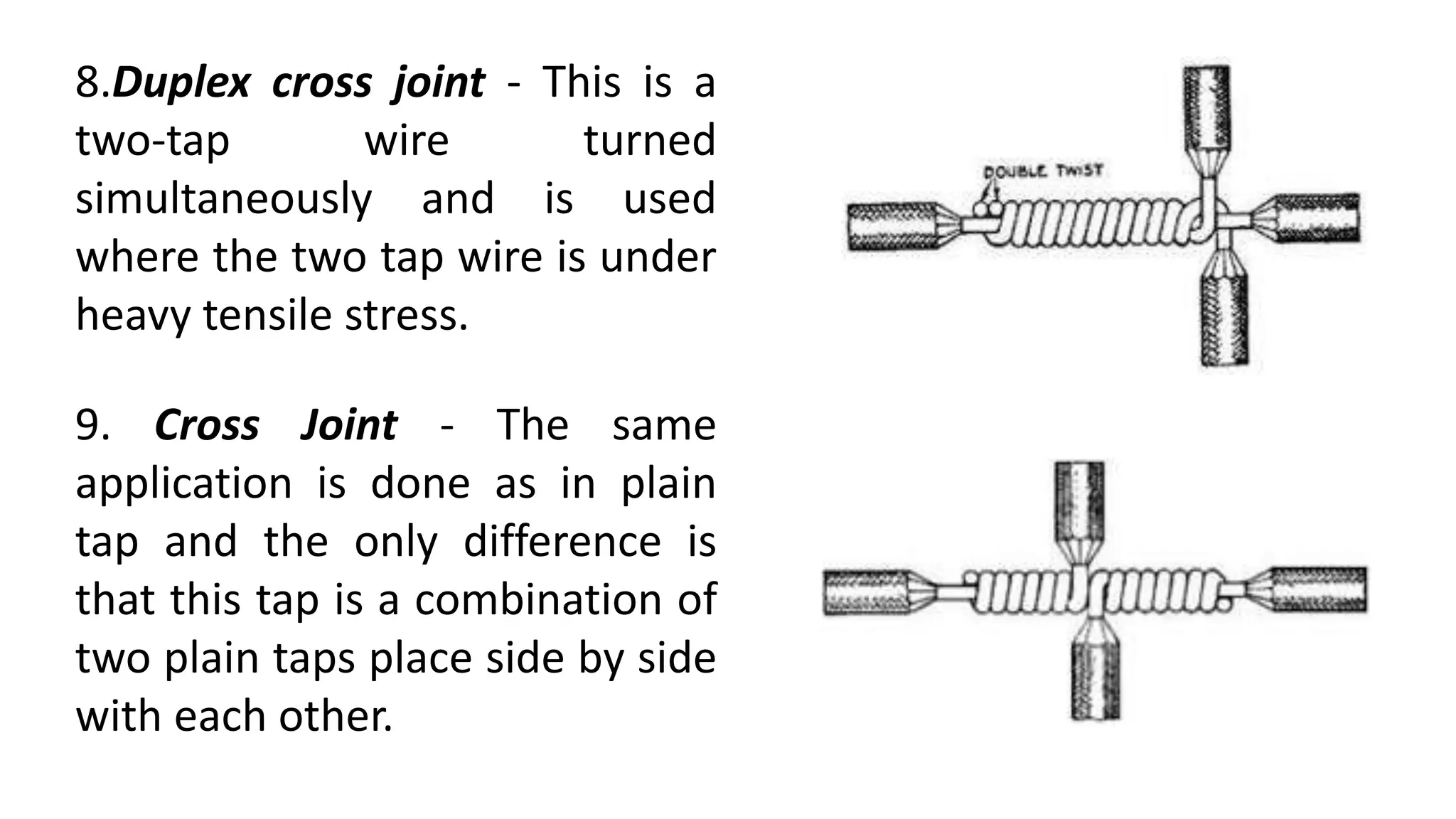

This document discusses tools and techniques for making electrical connections and splices. It describes common tools used for soldering like soldering irons, cutters, and multi-testers. Soldering involves melting alloy to create strong bonds between electronic parts. The document outlines various wire splicing methods like western union short-tie and long-tie splices used to extend wire lengths. It also details different jointing techniques for connecting power cables, such as britannia, tee, knotted tap, and duplex cross joints.