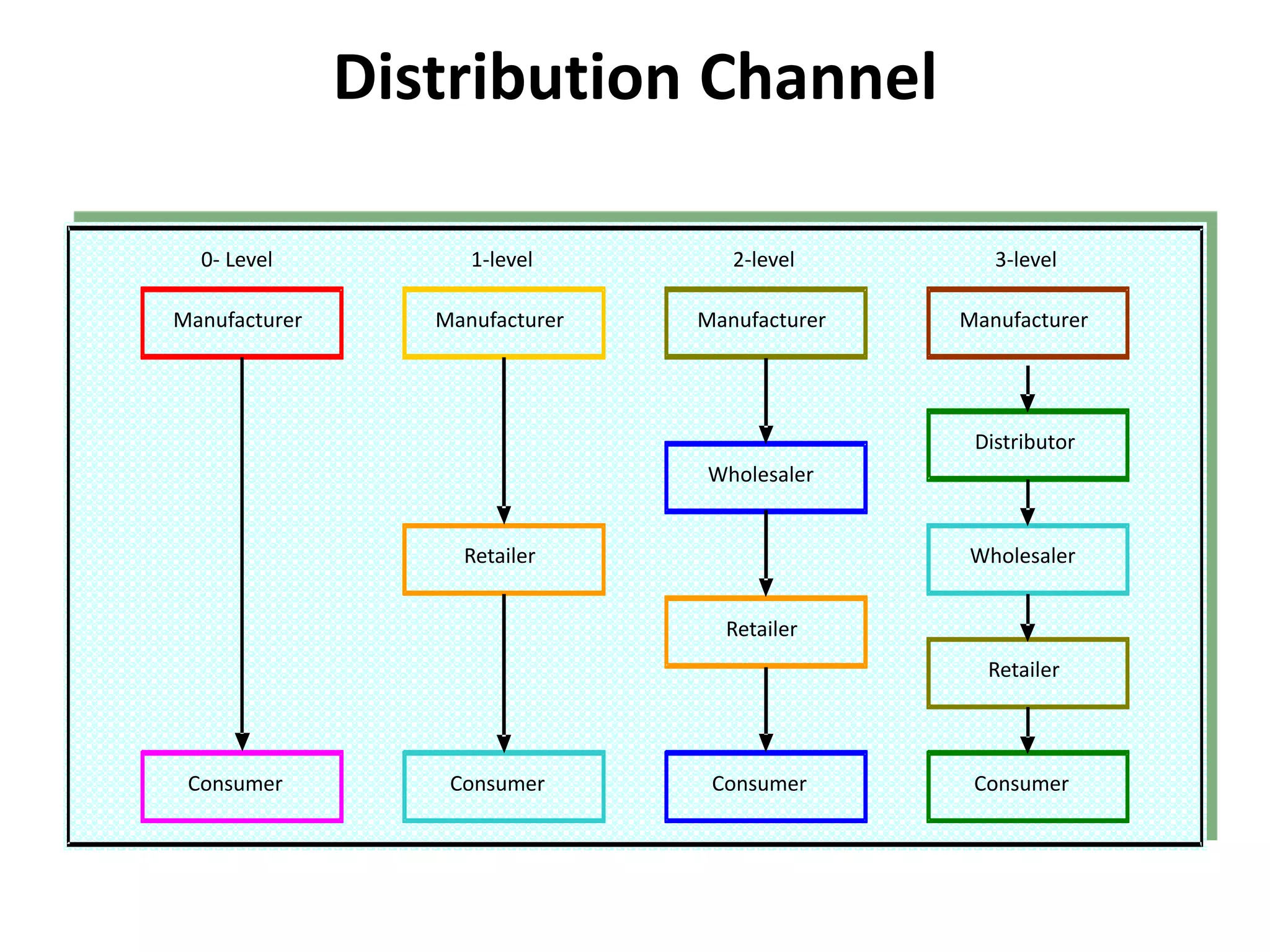

Distribution channels involve intermediaries that make products available to consumers. They include manufacturers, distributors, wholesalers and retailers. Physical distribution systems contain elements like warehousing, transportation, inventory control and order processing. Warehousing involves storage and redistribution of goods. Transportation choices affect costs and delivery. Inventory decisions balance risks of stockouts and carrying costs. Order processing prepares and fulfills customer orders.