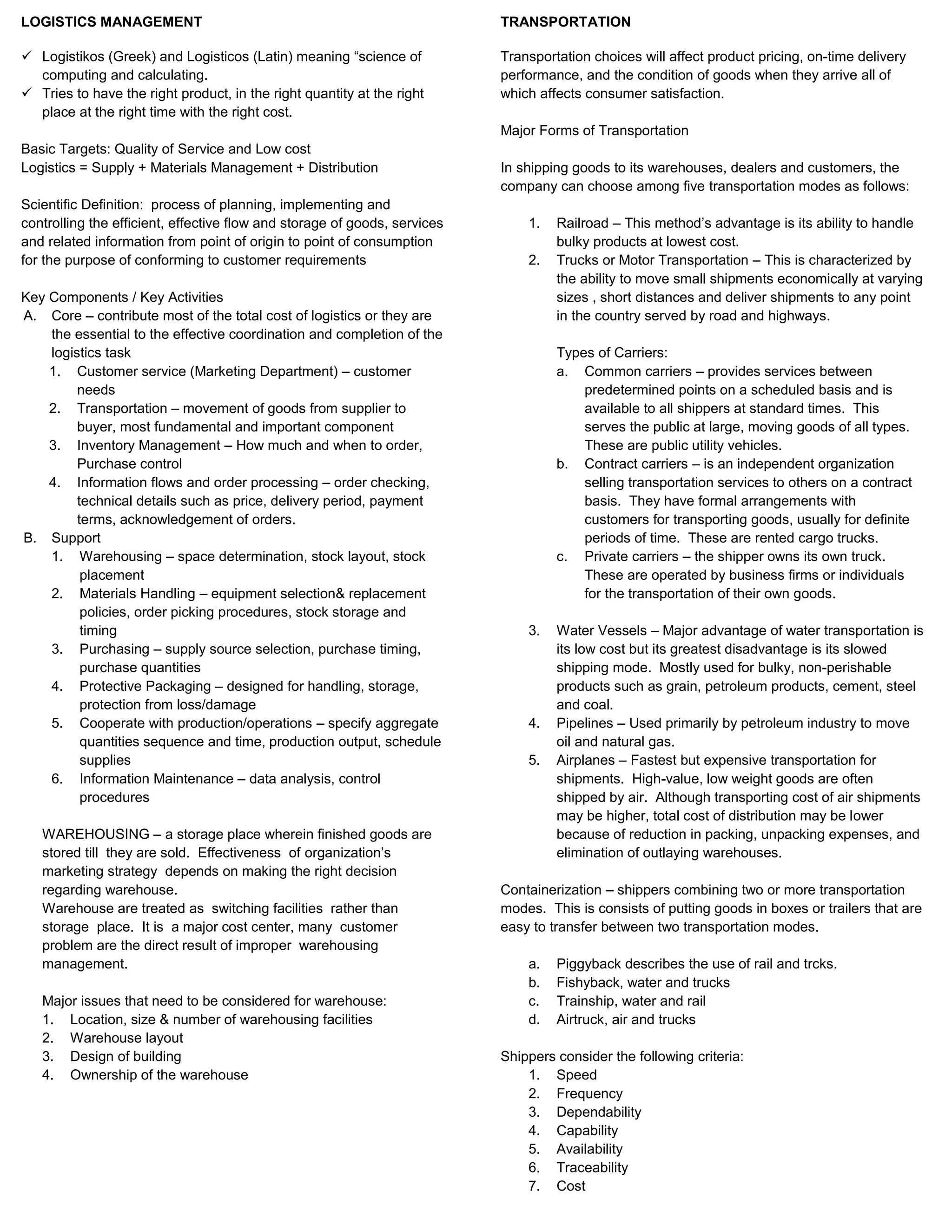

Logistics management aims to have the right products delivered to the right places at the right times at the lowest cost. It involves planning and controlling the flow of goods from suppliers to customers. Key components include transportation, inventory management, information management, and warehousing. Transportation choices affect cost, delivery times, and product condition. Major transportation modes are railroad, trucks, water vessels, pipelines, and airplanes, with different advantages depending on factors like cost, speed, and cargo type. Shippers consider criteria like speed, dependability, and cost when choosing transportation. Transportation rates vary based on distance, cargo characteristics, risk, traffic volume, carrier liability, equipment needs, and special handling requirements.