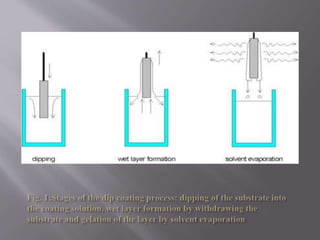

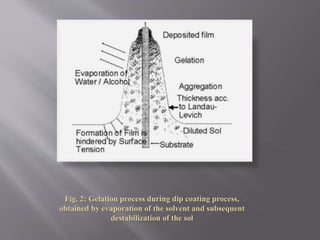

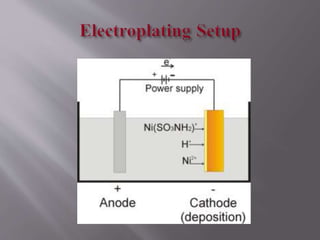

The document discusses dip coating and electrodeposition processes. It describes dip coating as a process where a substrate is immersed in a coating material tank, removed, and allowed to dry. The dip coating process has three stages: immersion, dwell time, and withdrawal. Film thickness is controlled by withdrawal speed and viscosity. Electrodeposition coats one metal onto another to modify surface properties like corrosion resistance. It can deposit thin layers with precision and is well-suited for nano- and microtechnologies. Both dip coating and electrodeposition are used for applications like solar panels, electronics, jewelry, and automotive and mechanical parts.