Dip coating is a process used to prepare porous ceramic membranes by immersing a substrate into a precursor solution, removing it, and allowing the coating to dry. It is an old commercially applied coating technique dating back to a 1939 patent. Key steps to forming defect-free membranes include using a homogeneous support, cleaning the substrate, sufficiently deaerating the solution, avoiding thick coatings, and keeping the environment particle-free. The dip coating process involves three stages: immersion for wetting, deposition and drainage as the substrate is withdrawn, and evaporation of the solvent to form the dried coating layer. Withdrawal speed and other forces determine the thickness of the coated layer.

![Dip Coating

Introduction

“Dip Coating refers to the immersing of a substrate

into a tank containing precursor solution, removing

the piece from the tank, and allowing it to drain.”

It is widely used for the preparation of porous

ceramic membranes.[1]](https://image.slidesharecdn.com/mukhtiar-160619223313/75/dip-coating-3-2048.jpg)

![Dip Coating

Steps to form defect-free membranes[2]:

A homogenous support

Substrate cleaning and filtration

Sufficient de-aeration of sol/suspension

Not too thick coating which results in drying

shrinkage and tensile stress

Avoid dust and other foreign particulates in air or

coating fluids](https://image.slidesharecdn.com/mukhtiar-160619223313/75/dip-coating-5-2048.jpg)

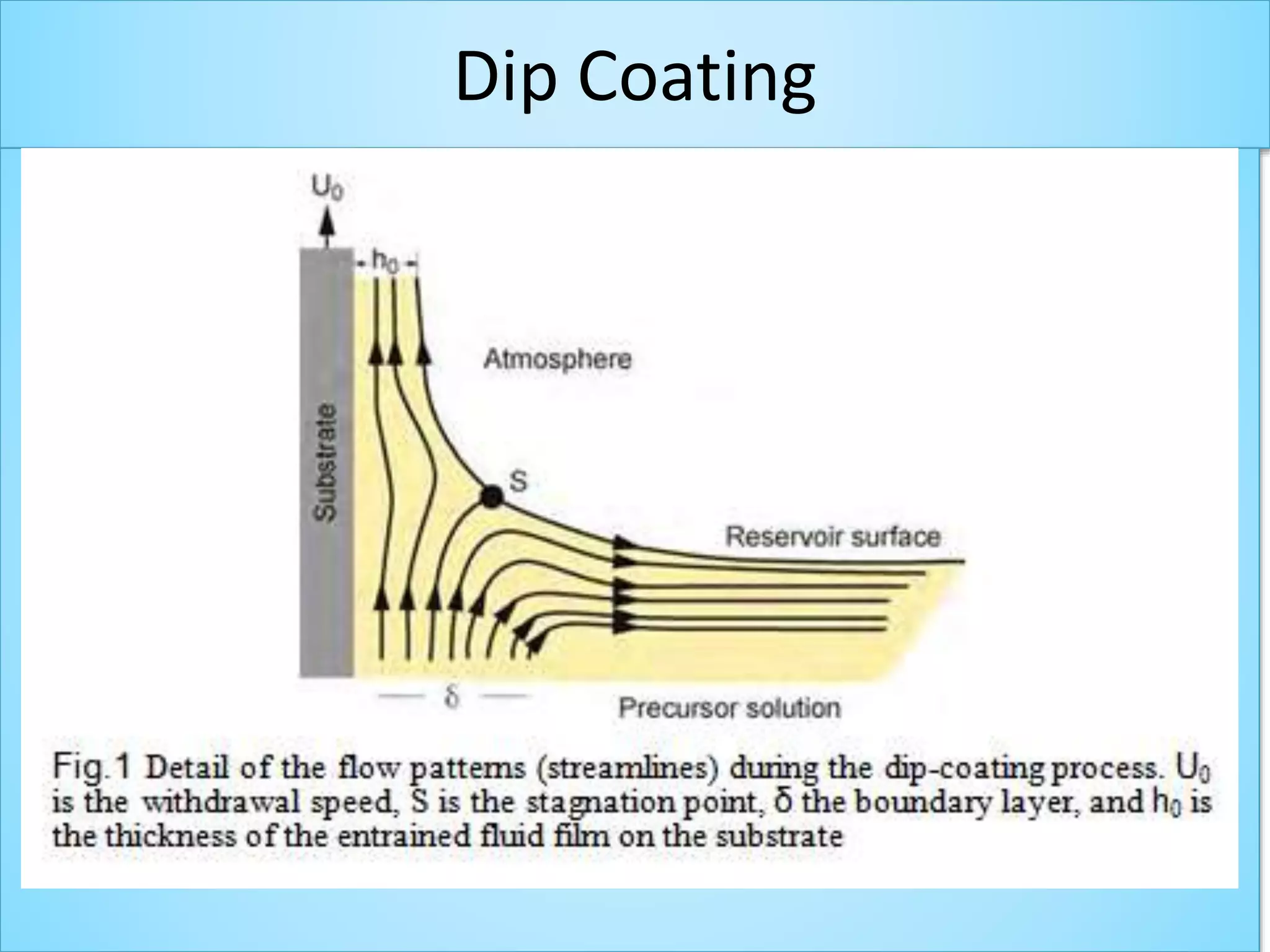

![Dip Coating

Process

The process may be separated into three important technical

stages[3]:

Immersion & dwell time: The substrate is immersed into the

precursor solution at a constant speed followed by a certain

dwell time in order to leave sufficient interaction time of the

substrate with the coating solution for complete wetting.

Deposition & Drainage: By pulling the substrate upward at a

constant speed a thin layer of precursor solution is entrained, i.e.

film deposition. Excess liquid will drain from the surface.](https://image.slidesharecdn.com/mukhtiar-160619223313/75/dip-coating-6-2048.jpg)

![Dip Coating

References:

[1] Geffcken W, Berger E (1939) Verfahren zur Anderung des Reflexionsvermogen

Gla¨ser. Deutsches Reichspatent, assigned to Jenaer Glaswerk Schott & Gen.,

Jena 736 41

[2] Scriven LE (1988) Physics and application of dip-coating and spin-coating In:

Brinker CJ Clark DE, Ulrich DR (eds) Better ceramics through chemistry III,

vol 121, Materials Research

[3] Grosso D (2011) How to exploit the full potential of the dip-coating process to

better control film formation. J Mater Chem 21:17033–17038](https://image.slidesharecdn.com/mukhtiar-160619223313/75/dip-coating-10-2048.jpg)