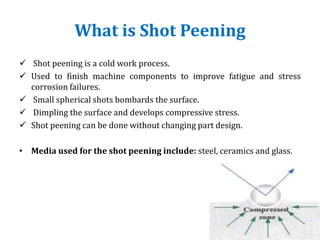

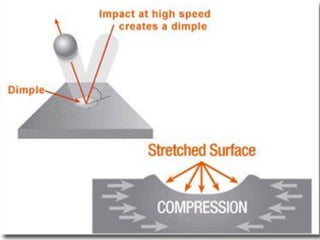

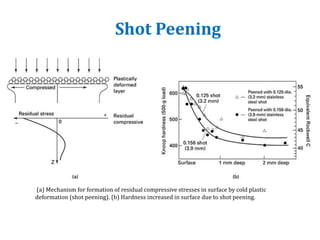

Shot peening was discovered centuries ago by blacksmiths who found it increased the strength of swords and wagon springs. It is a cold working process where small spherical shots are projected at high velocity onto a metal surface, dimpling and inducing compressive stresses that increase fatigue life. While shot blasting uses abrasives to clean surfaces, shot peening uses precisely controlled round media to impart a compressive layer that reduces tensile stresses and cracking. It is commonly used on automotive and machinery parts like gears, camshafts, and turbine blades.