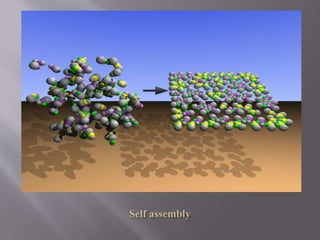

Nanomanufacturing involves producing materials and parts on the nanoscale using either top-down or bottom-up approaches. The top-down approach starts with large pieces of material and makes them smaller through techniques like lithography, while the bottom-up approach builds up structures atom by atom through self-assembly and deposition. Nanomanufacturing allows precise control at the atomic scale, which gives materials unique properties. Current applications include electronics, sensors, and information storage, while potential future applications could expand to fields like aviation, nanobots, and pharmaceuticals.