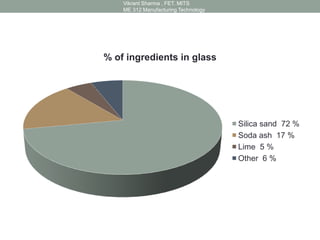

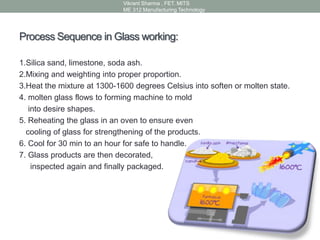

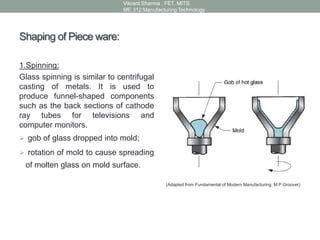

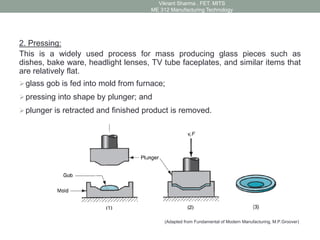

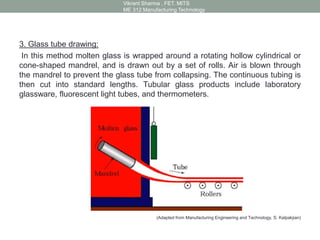

The document discusses the manufacturing process for glass. It begins by describing the composition of glass, which consists mainly of silica sand, soda ash, and lime. The document then outlines the basic process for glass production, which involves mixing the raw materials, melting them at high temperatures, forming the molten glass into shapes, and annealing to strengthen the final products. Several common shaping processes for different glass products are also summarized, including processes for pieceware, flat glass, tubing, and fibers.