This document provides an overview and introduction to Demand Flow Technology (DFT) workshop principles. It defines some key terms and concepts in DFT including:

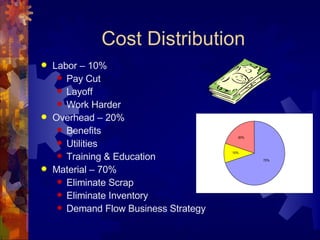

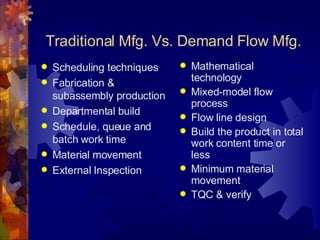

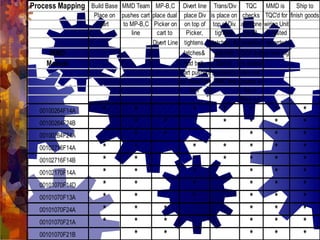

1) DFT aims to eliminate waste and have products flow through production based on customer demand in pursuit of perfection.

2) The primary objective of DFT is to build high quality products in the shortest production time at the lowest possible cost.

3) Key advantages include minimizing non-value-added work, maintaining a continuous improvement process, and maximizing speed to market and customer responsiveness.