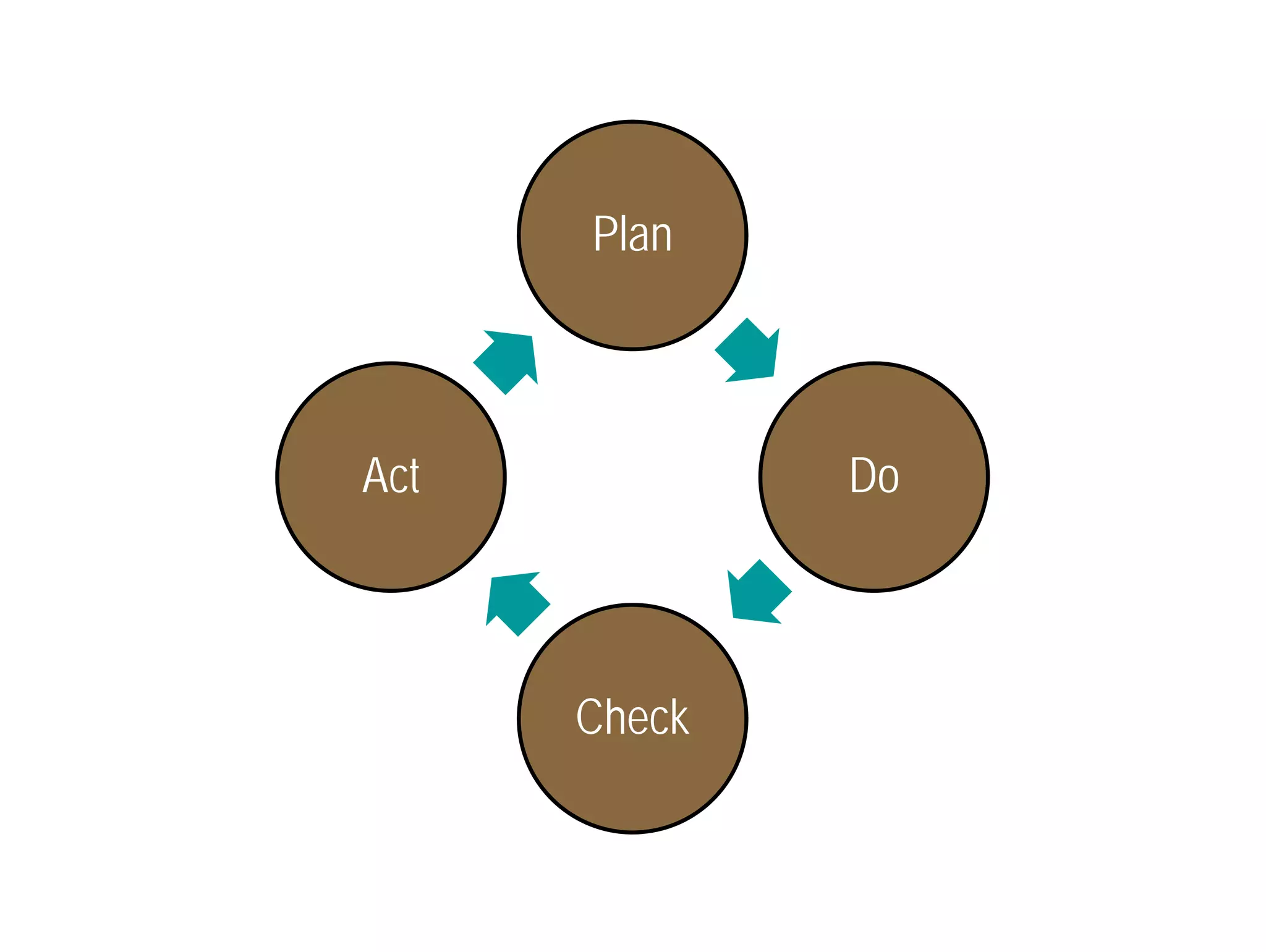

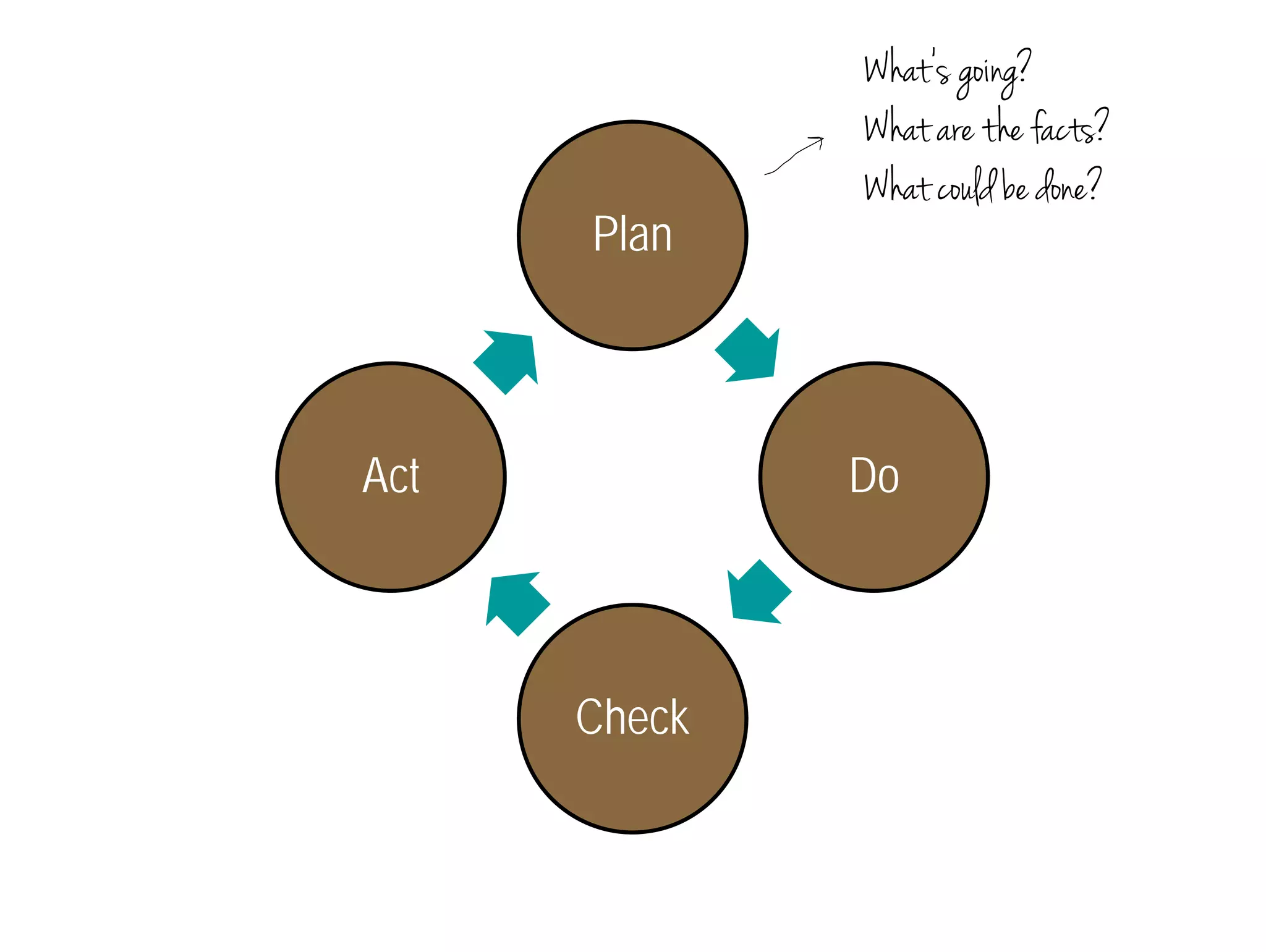

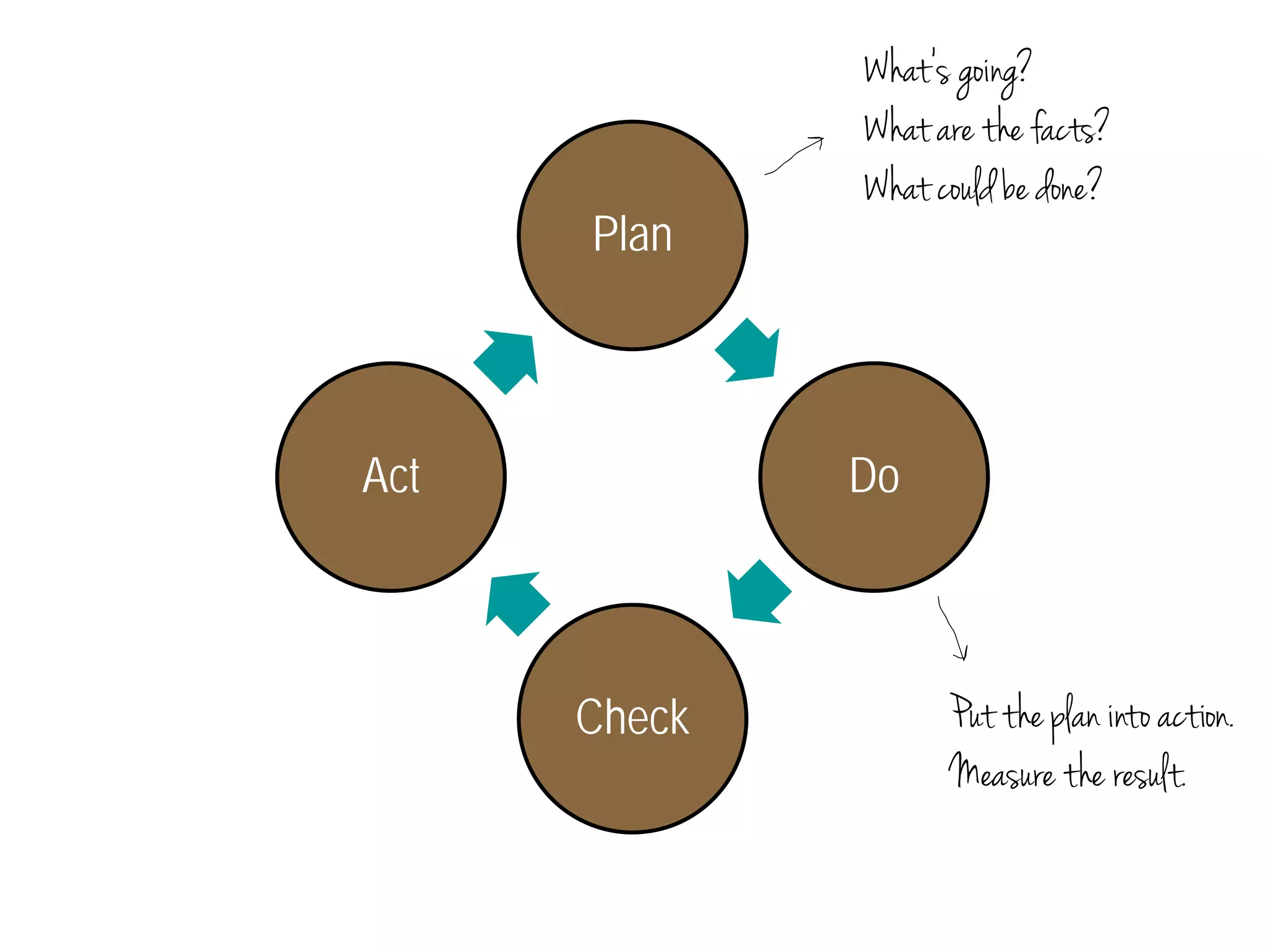

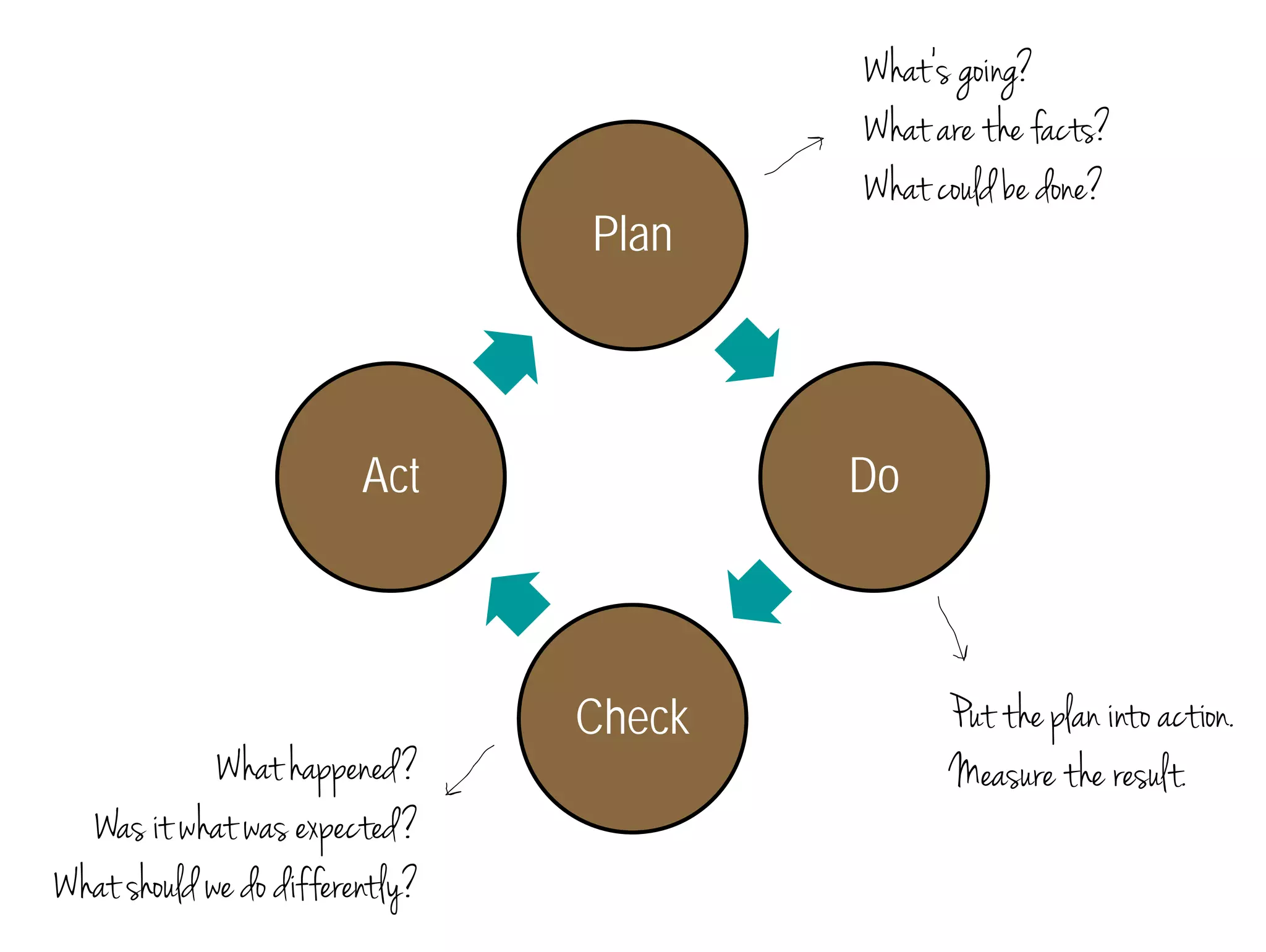

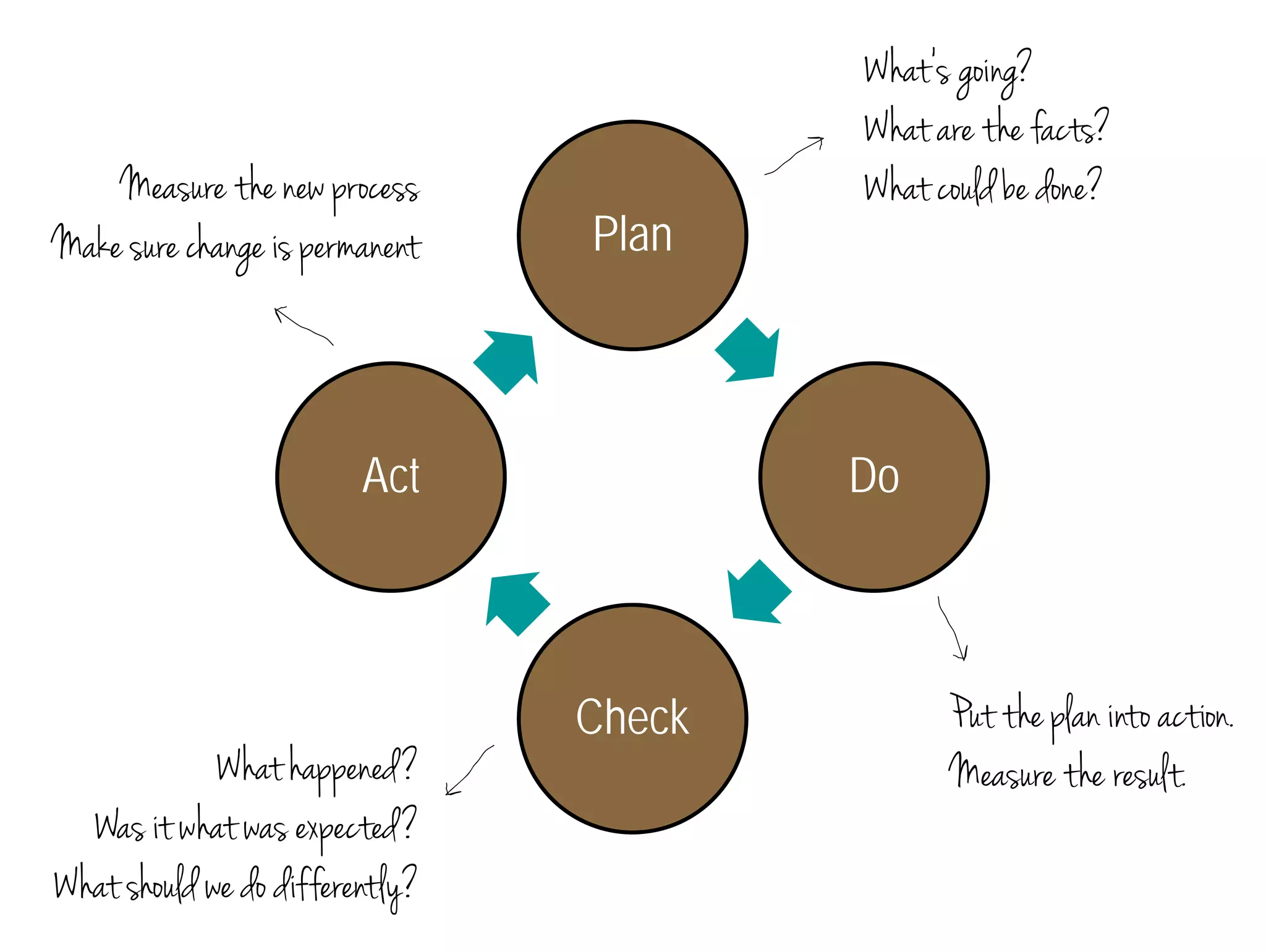

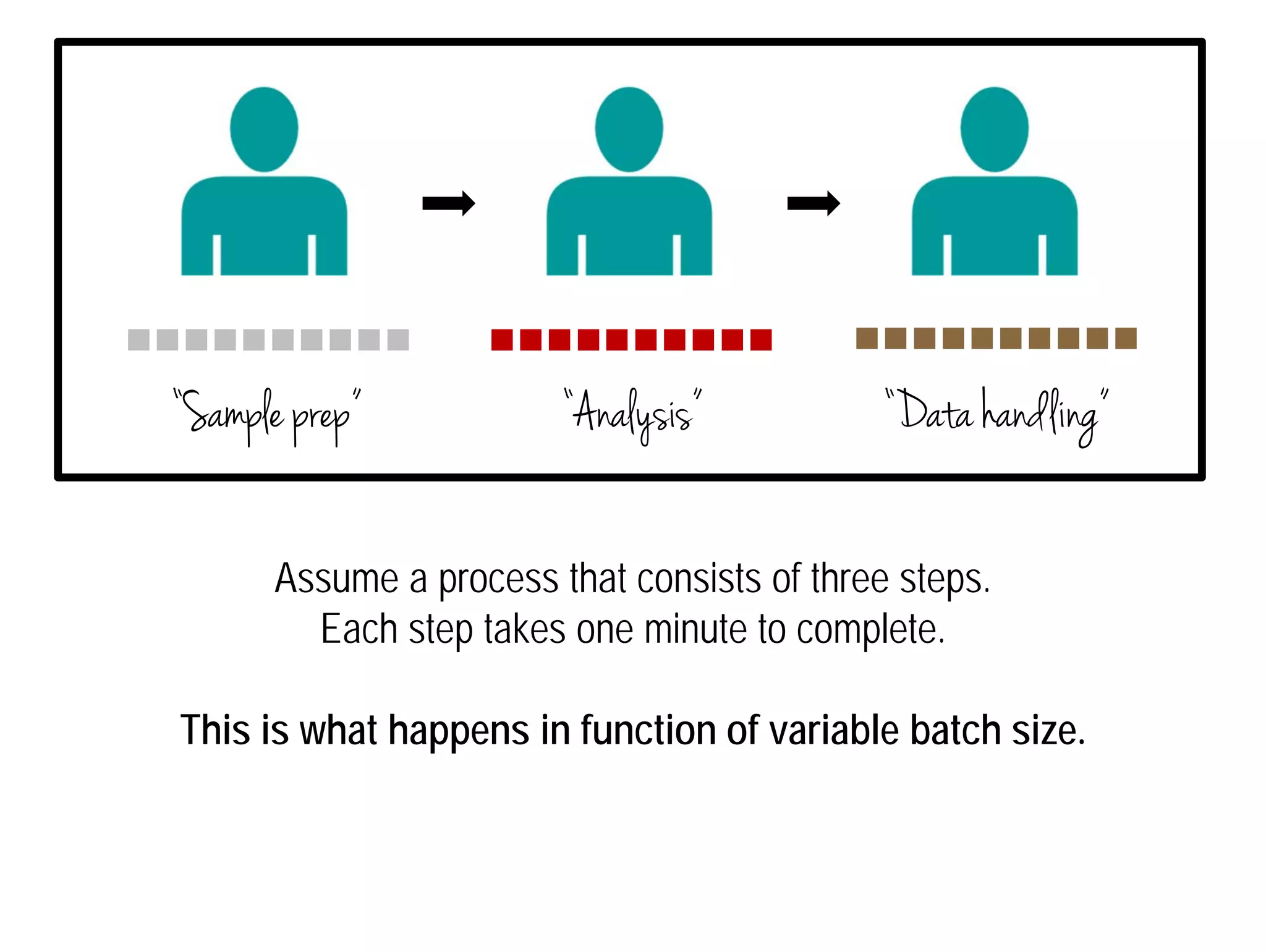

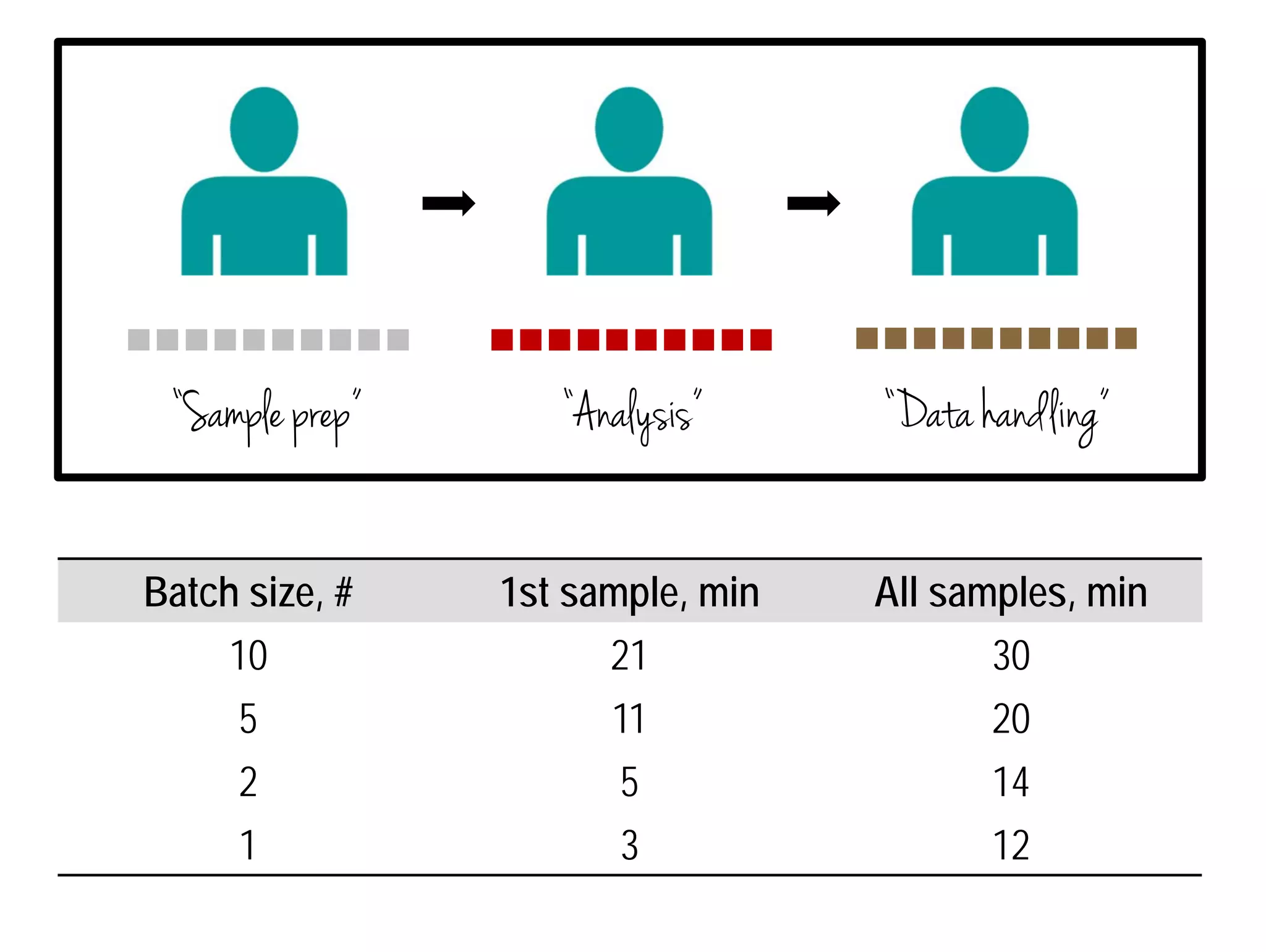

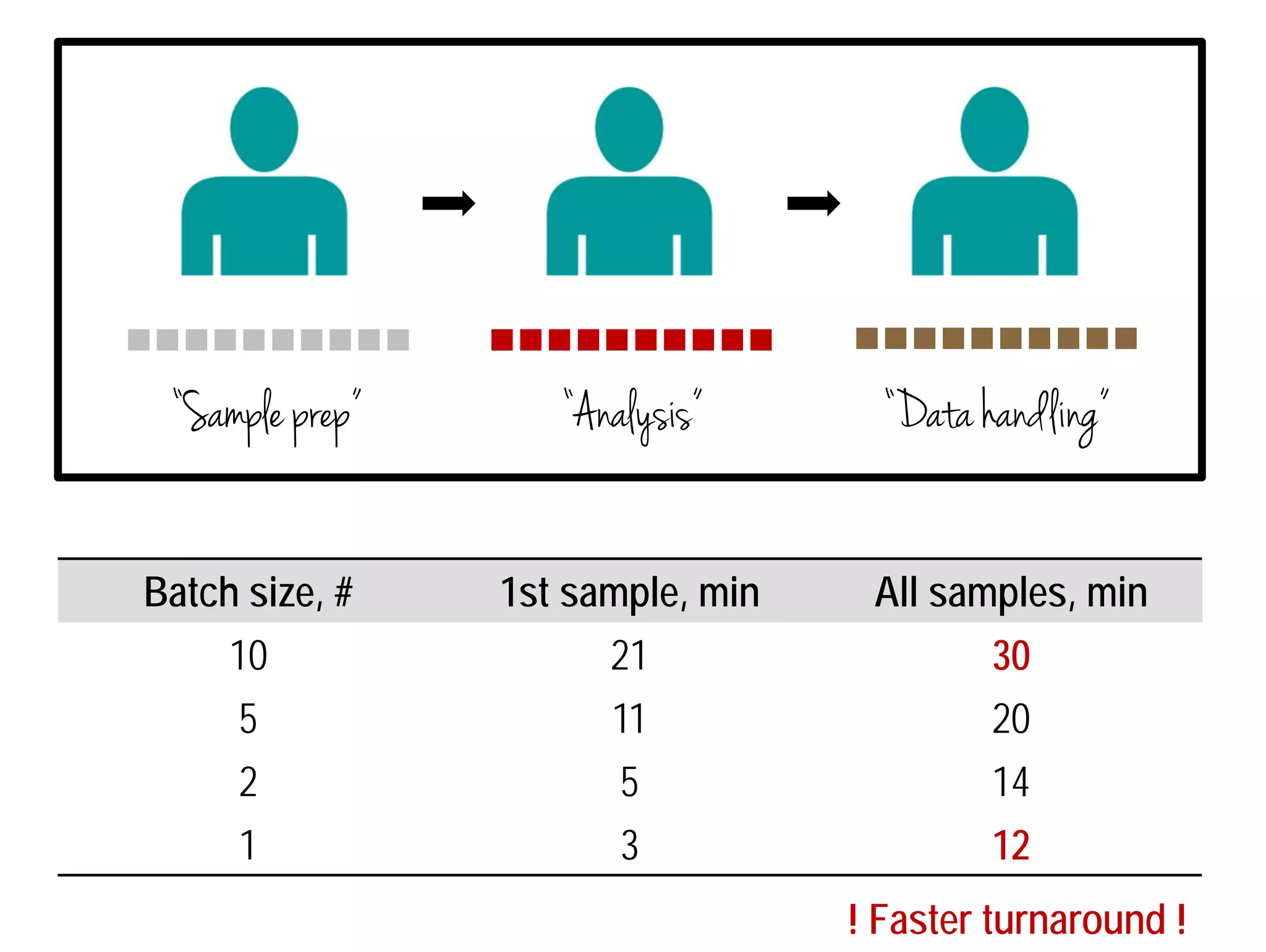

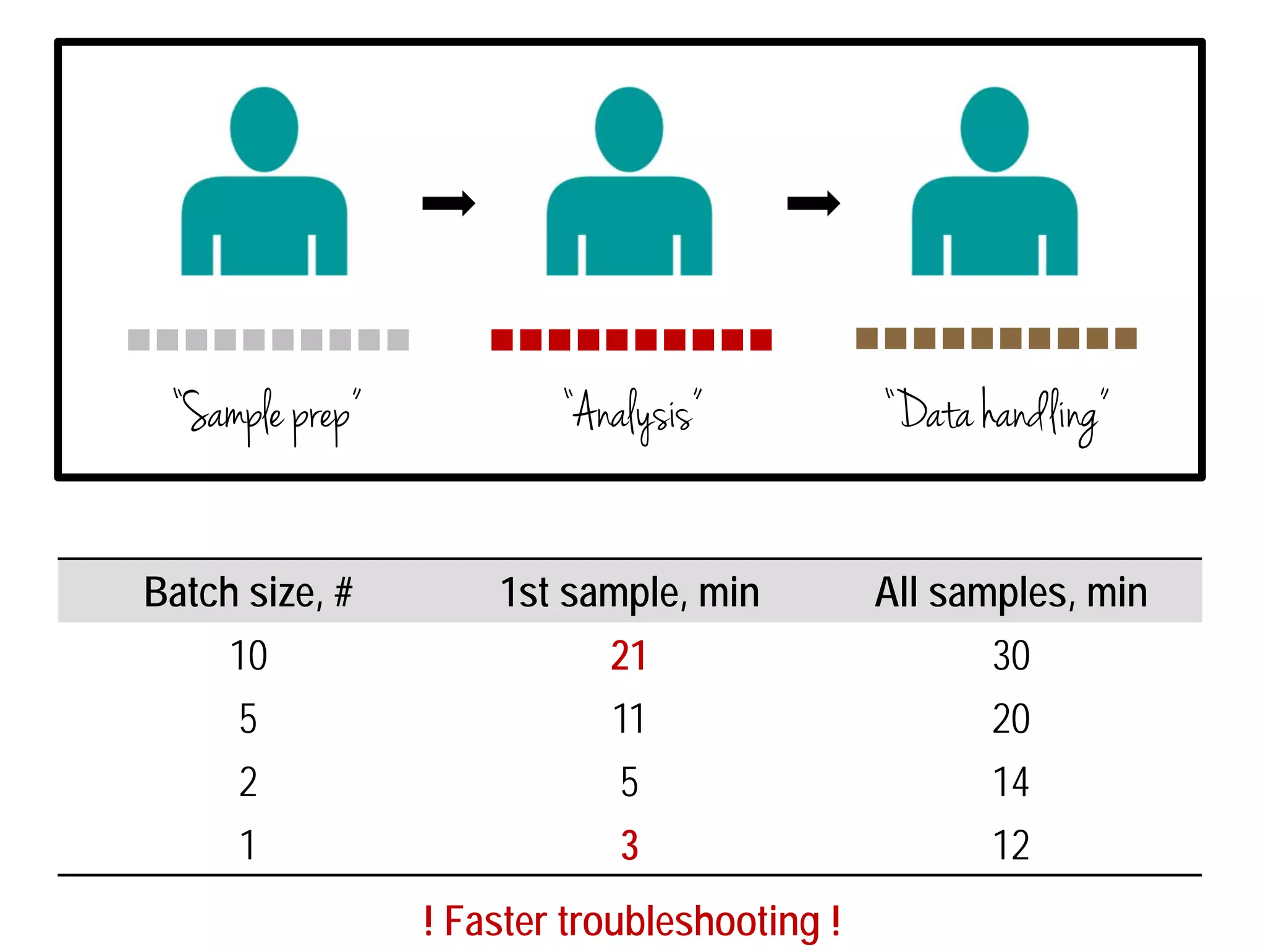

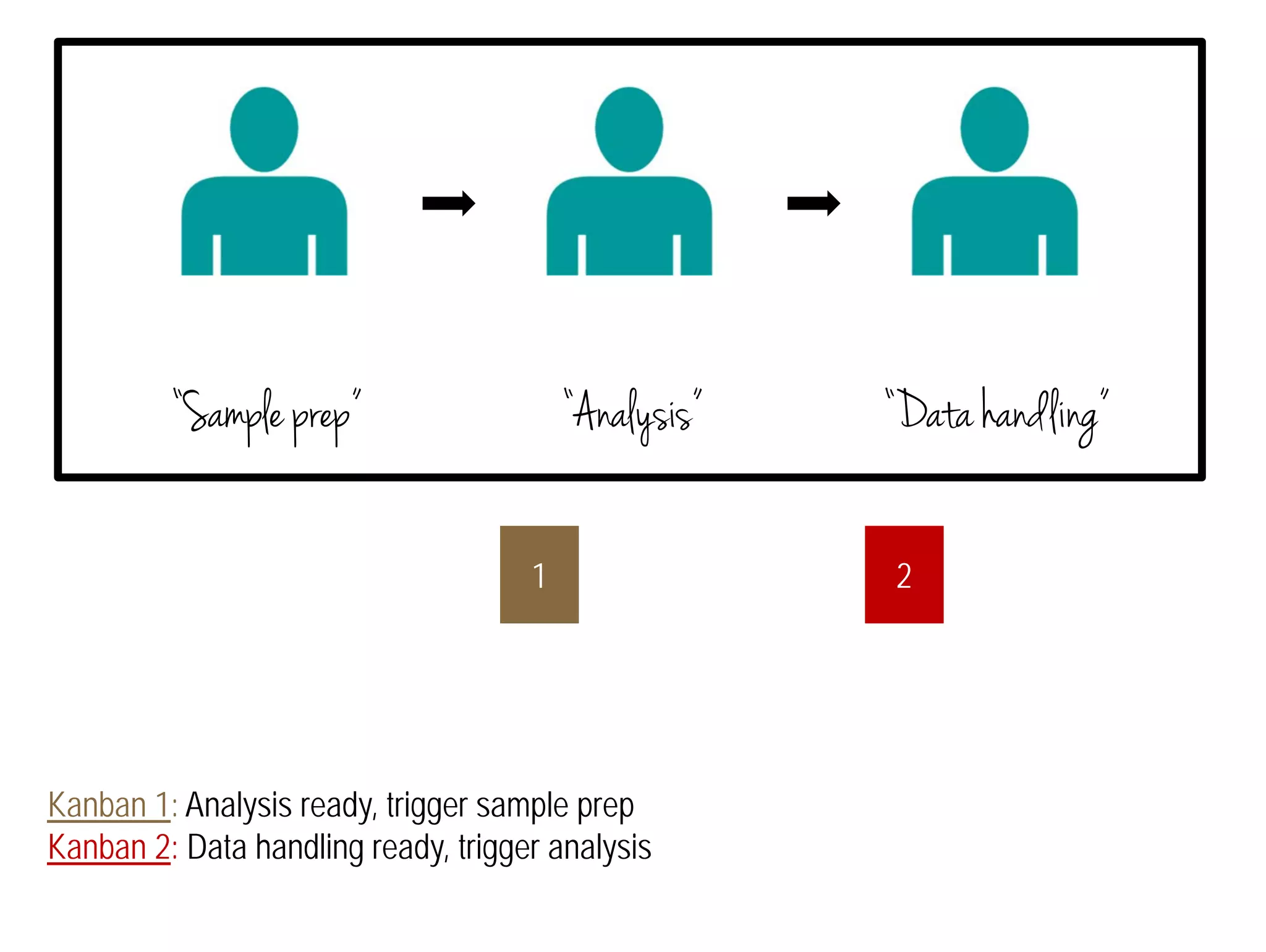

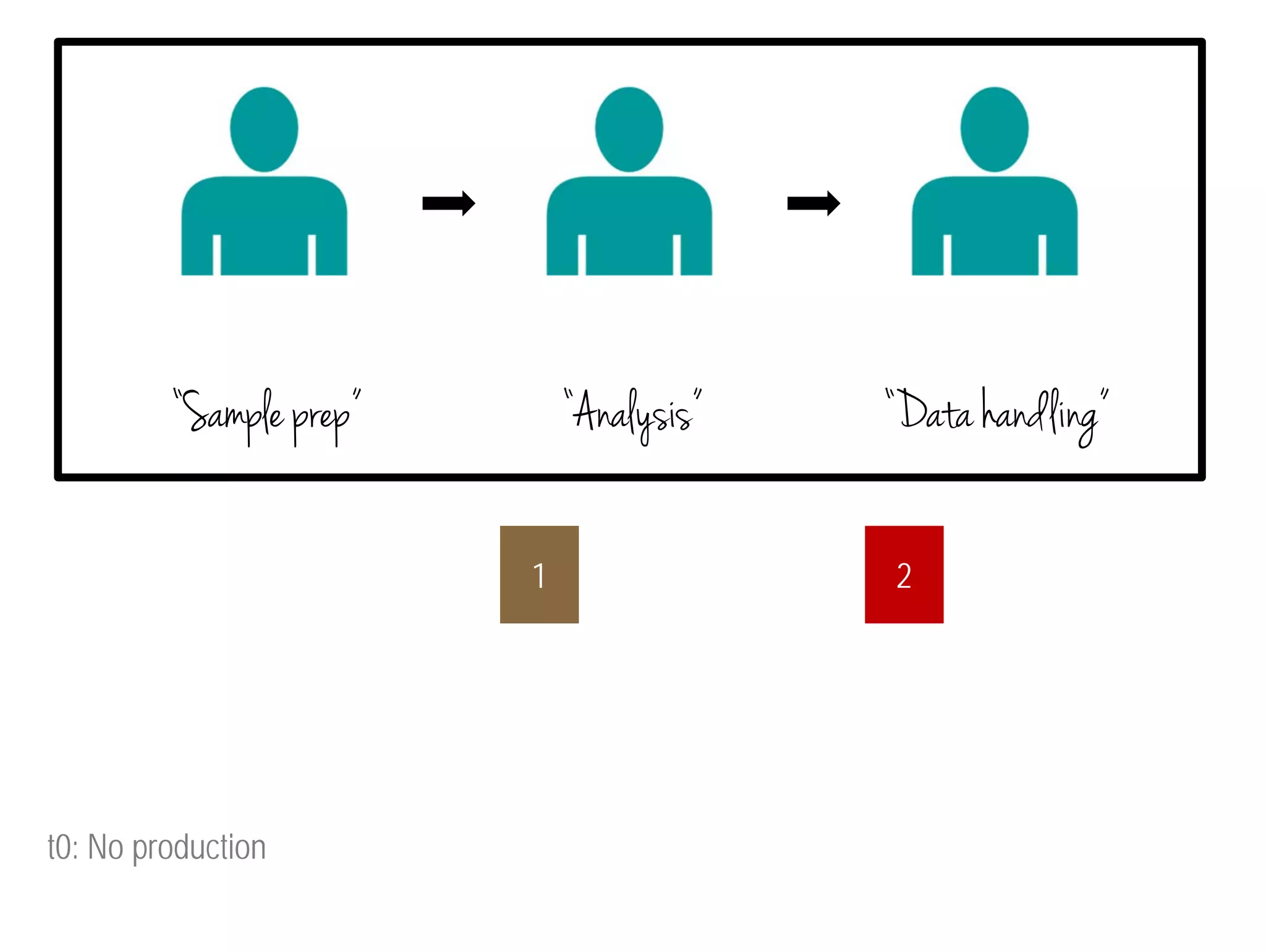

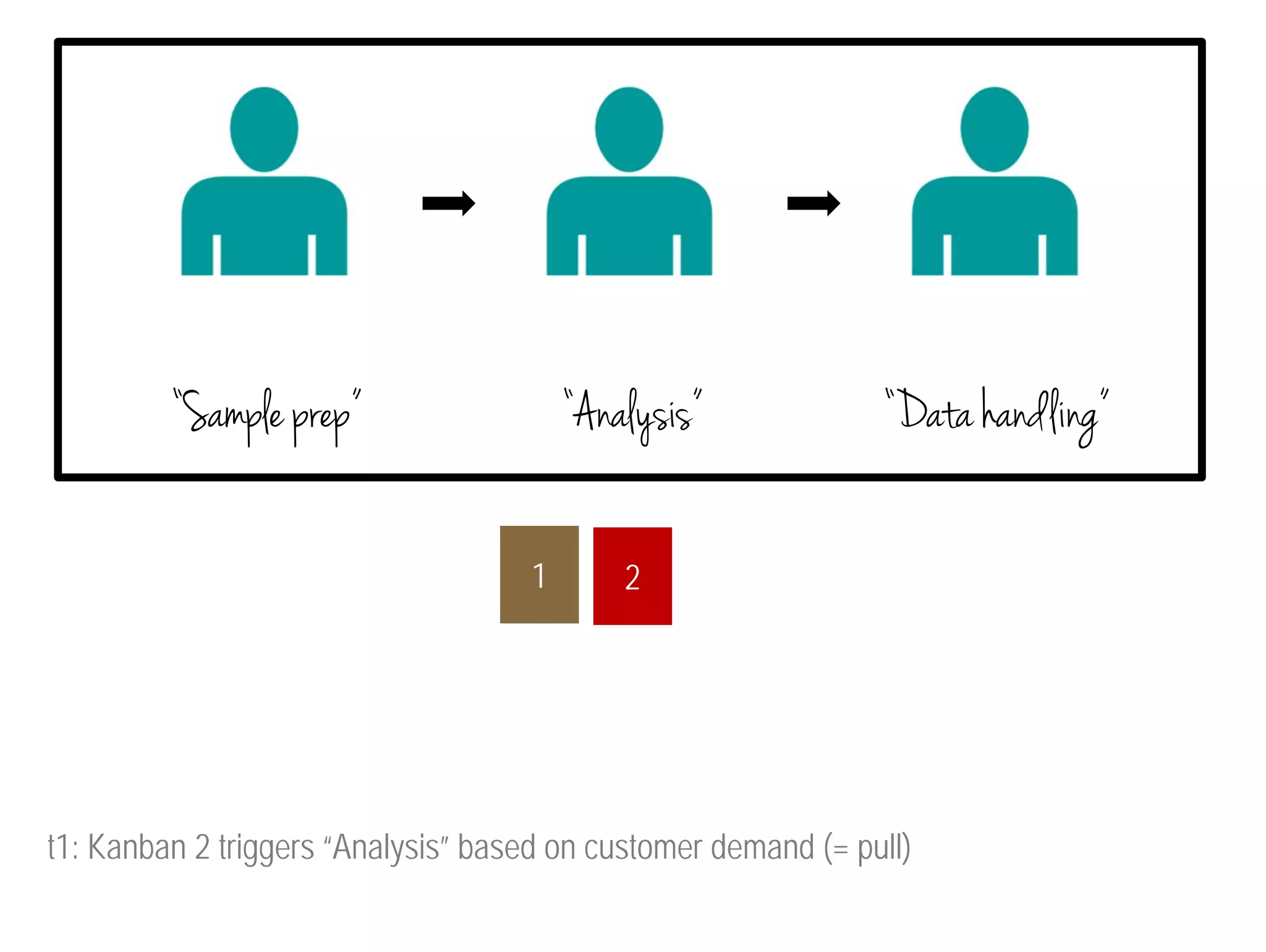

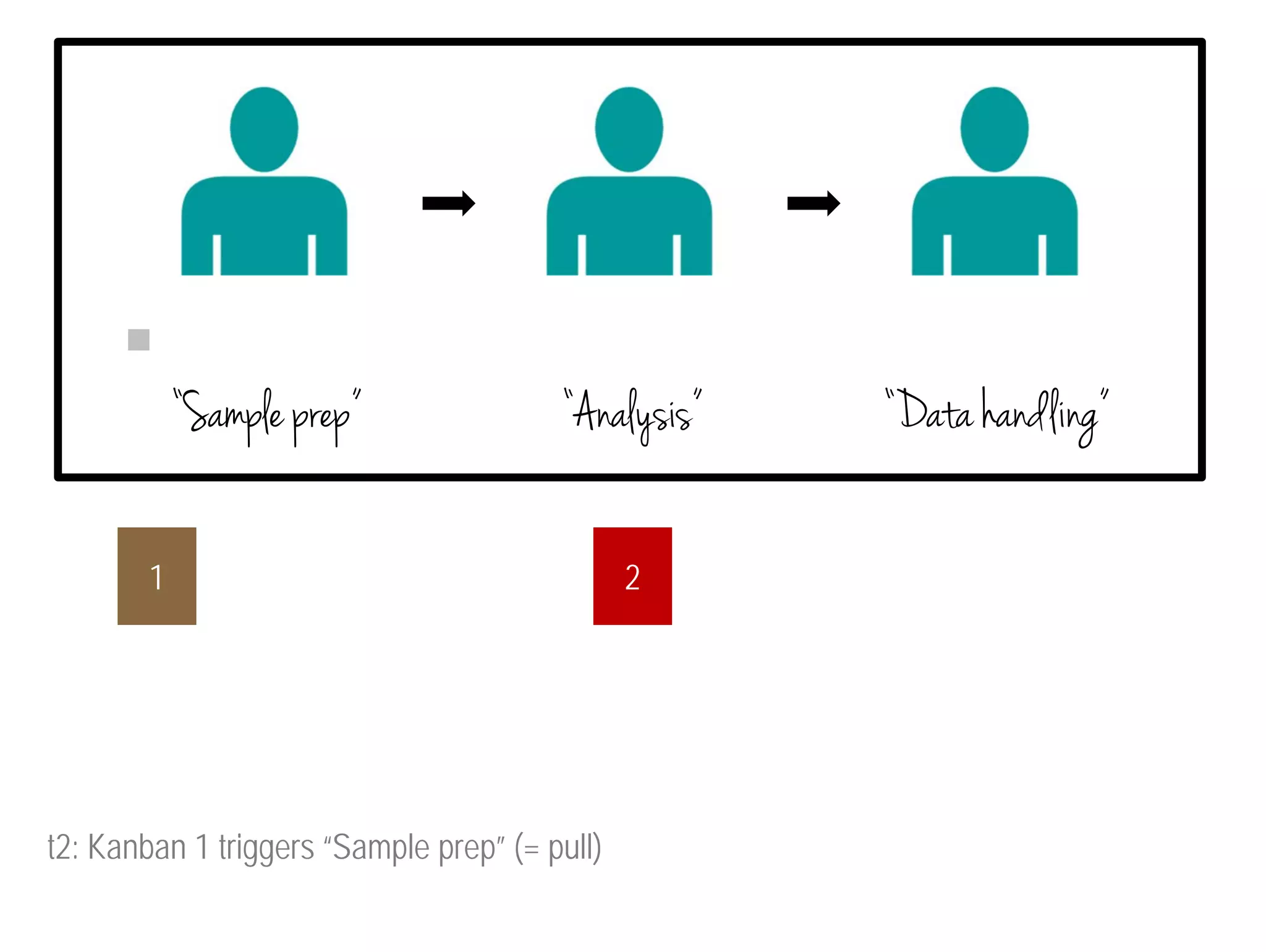

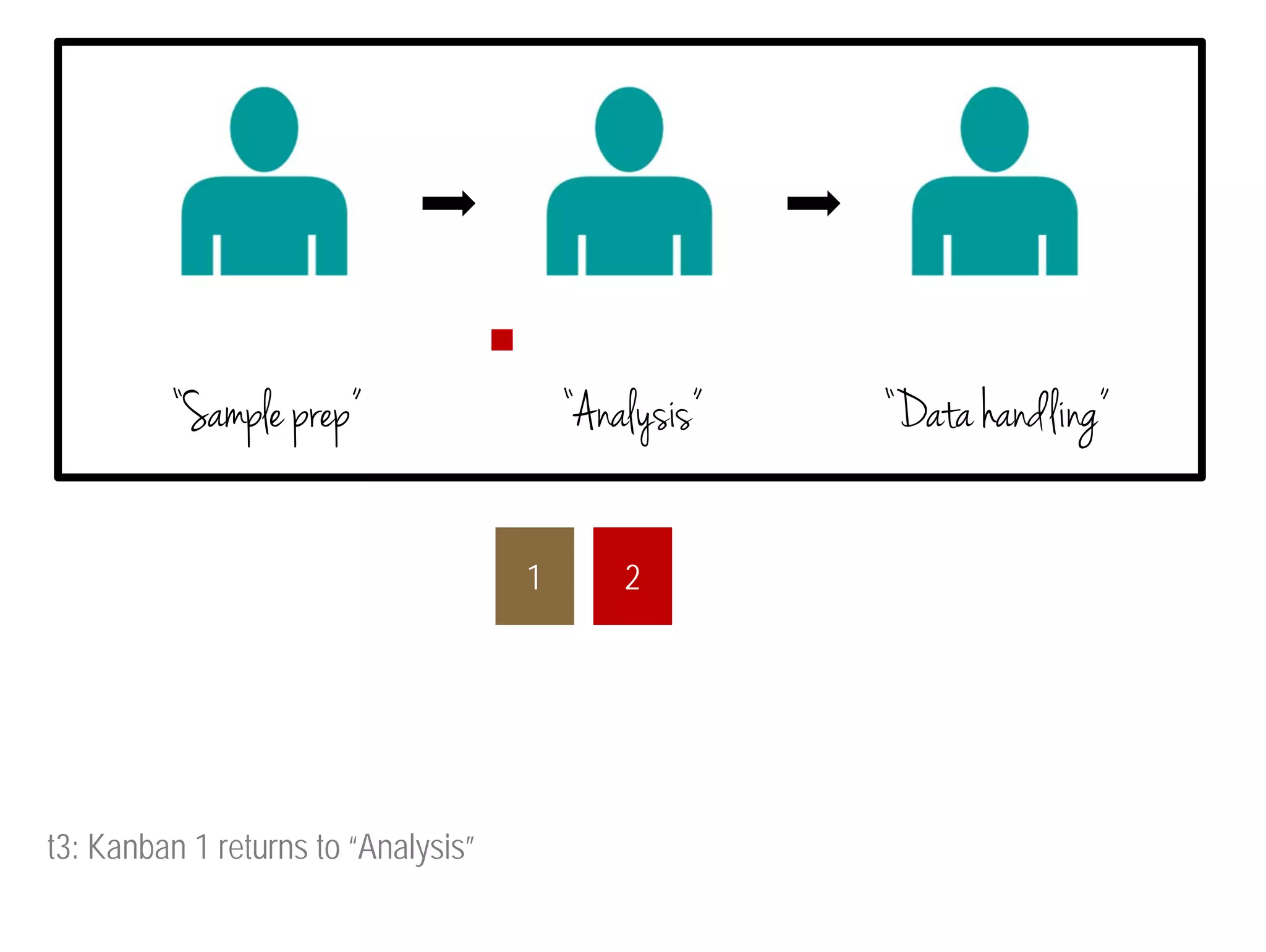

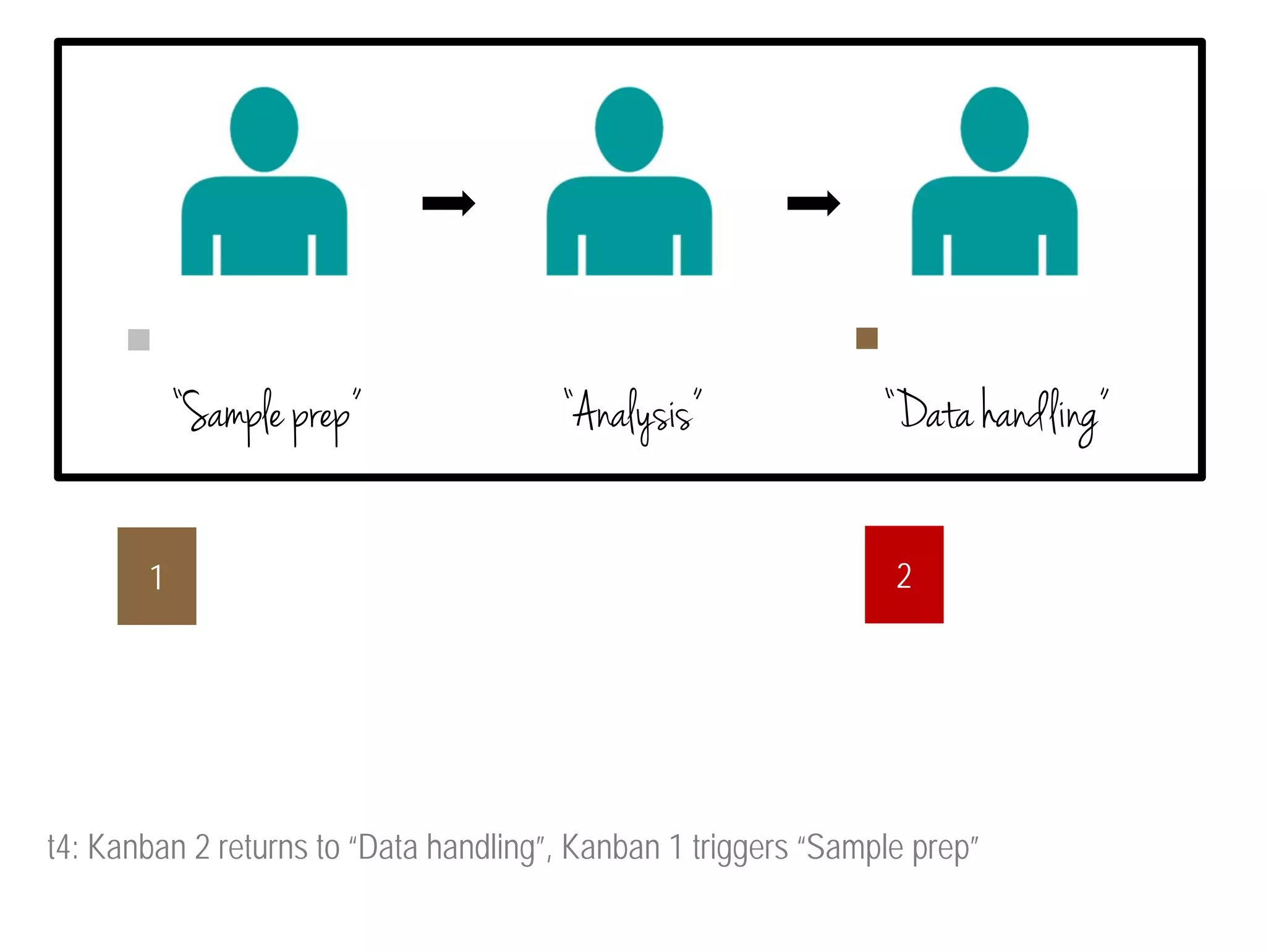

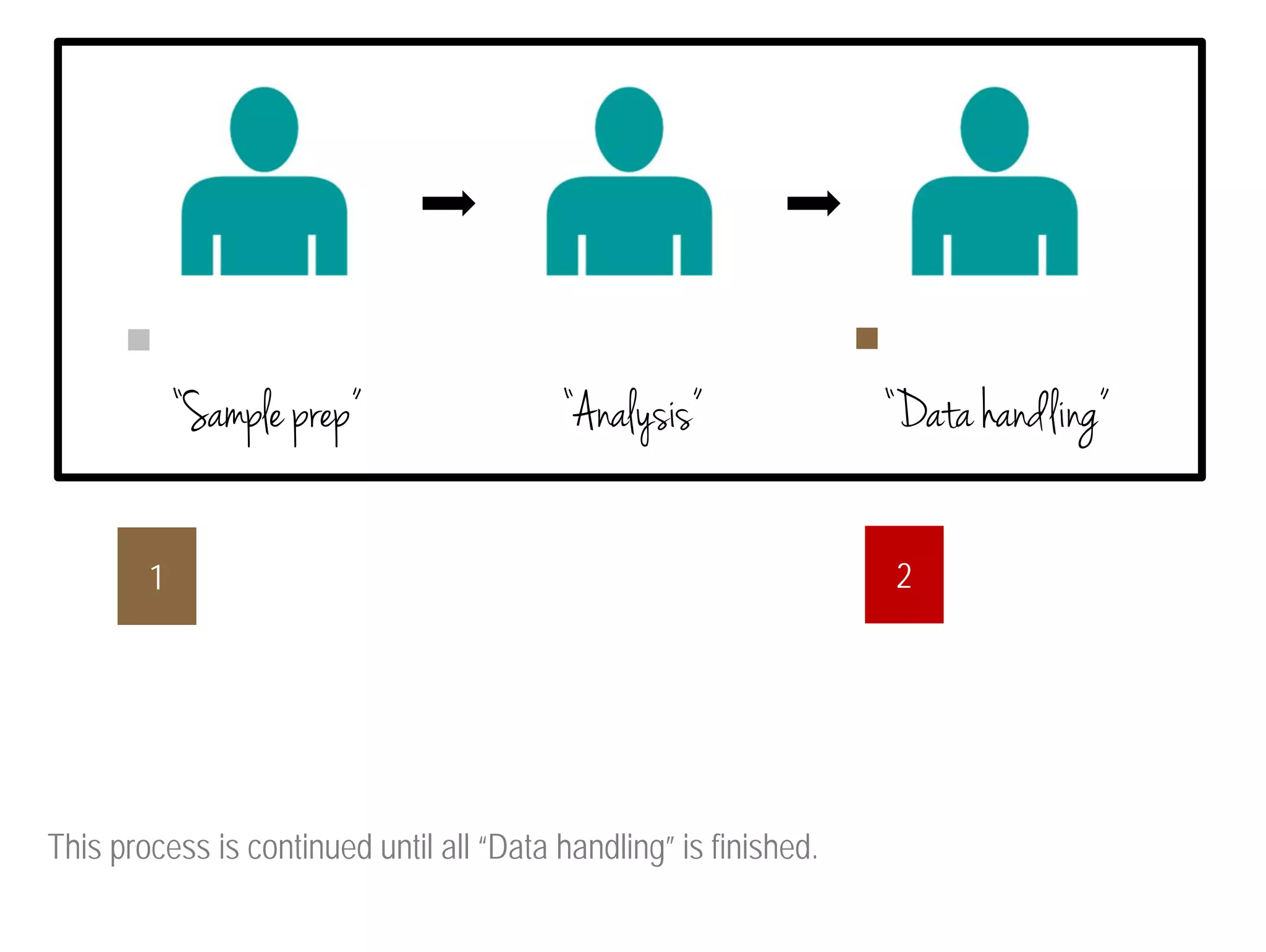

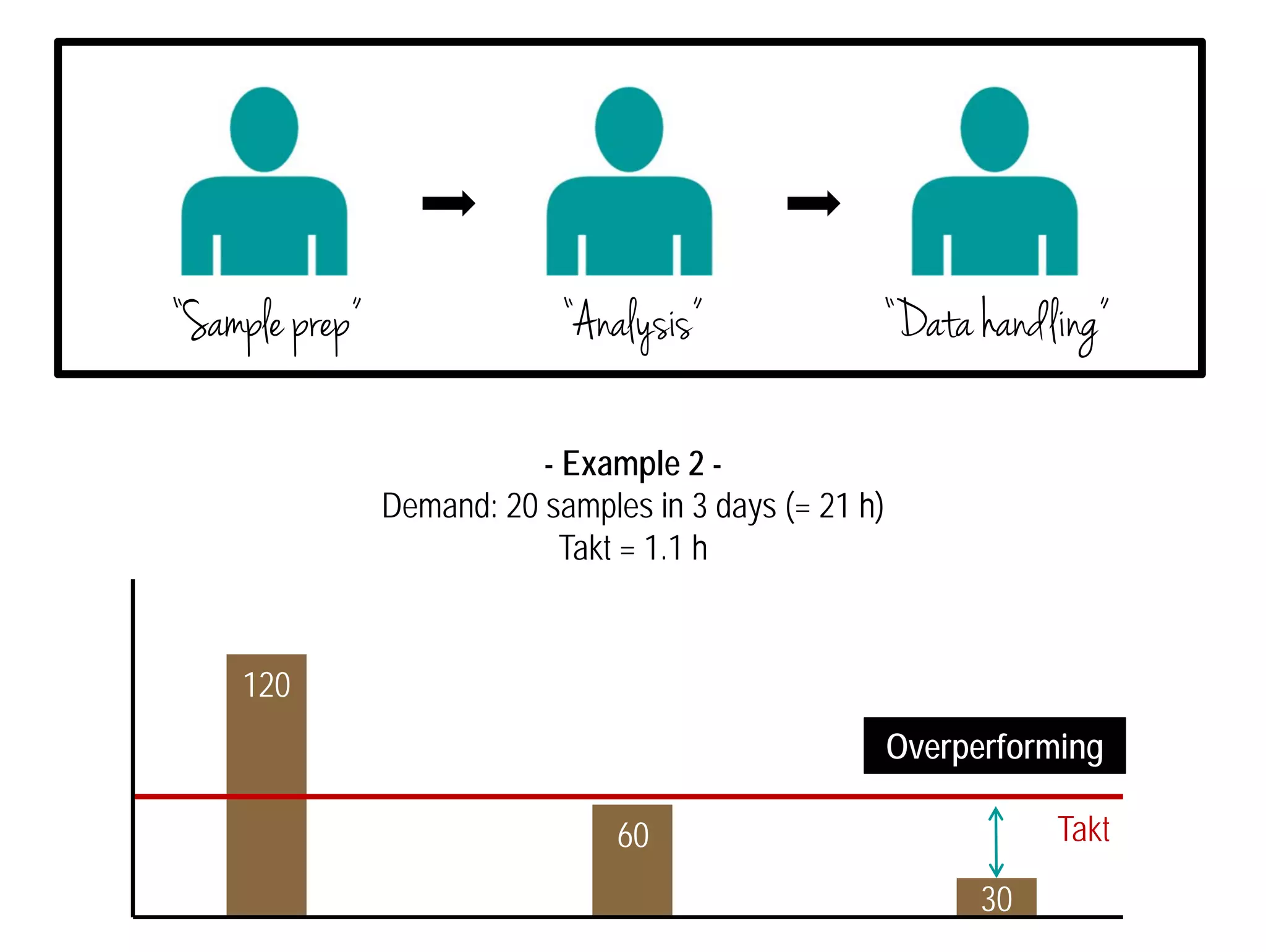

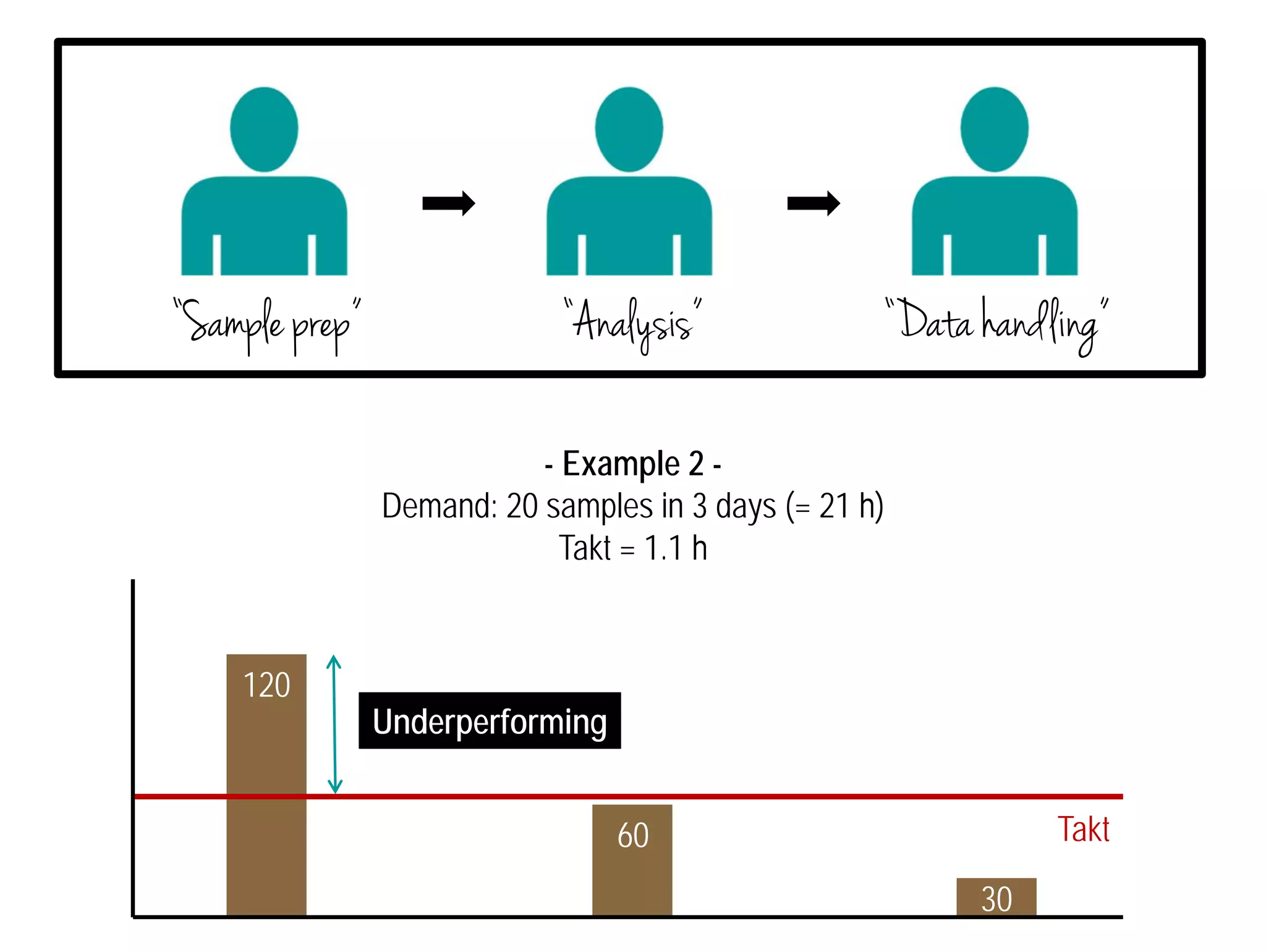

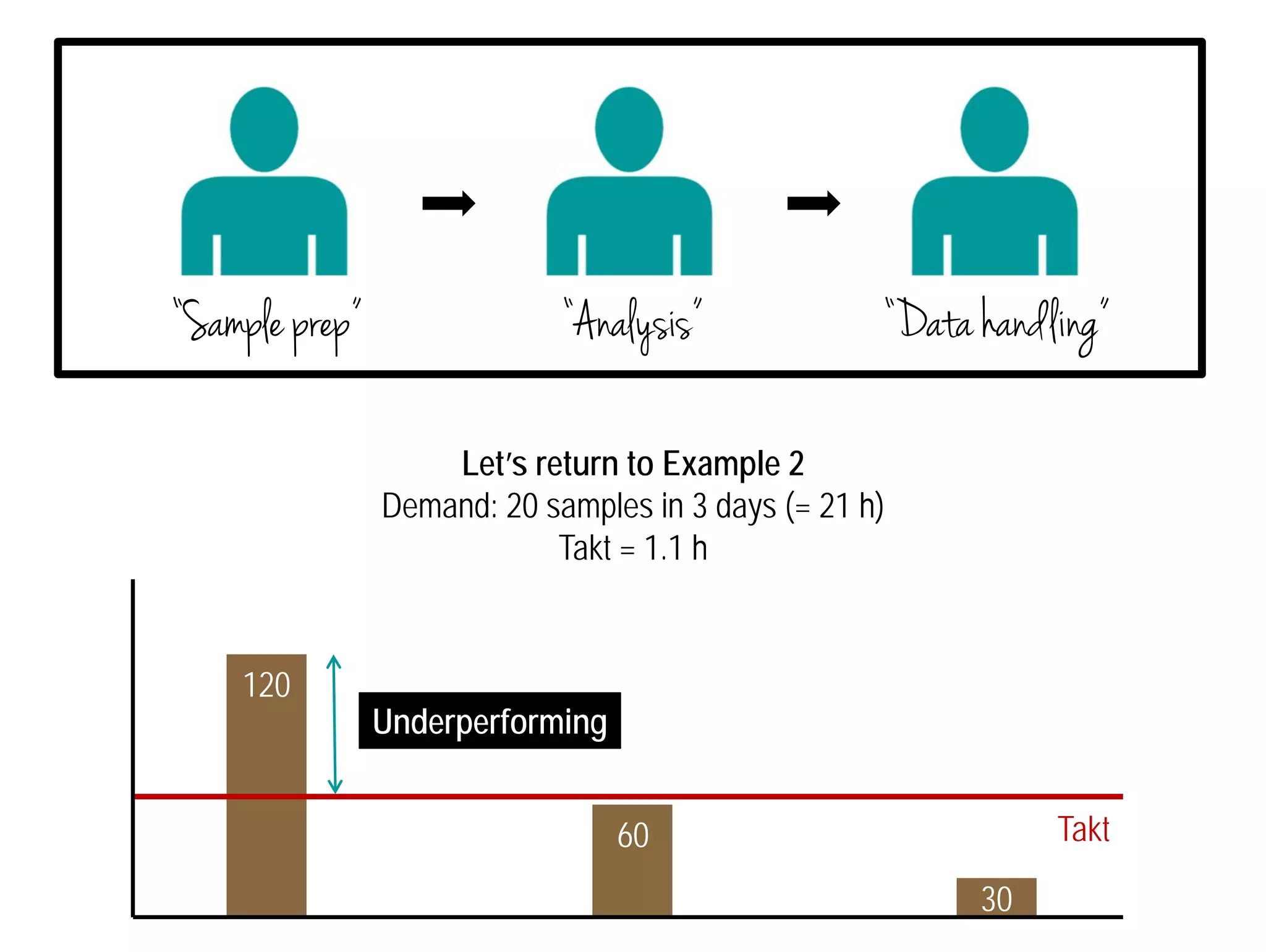

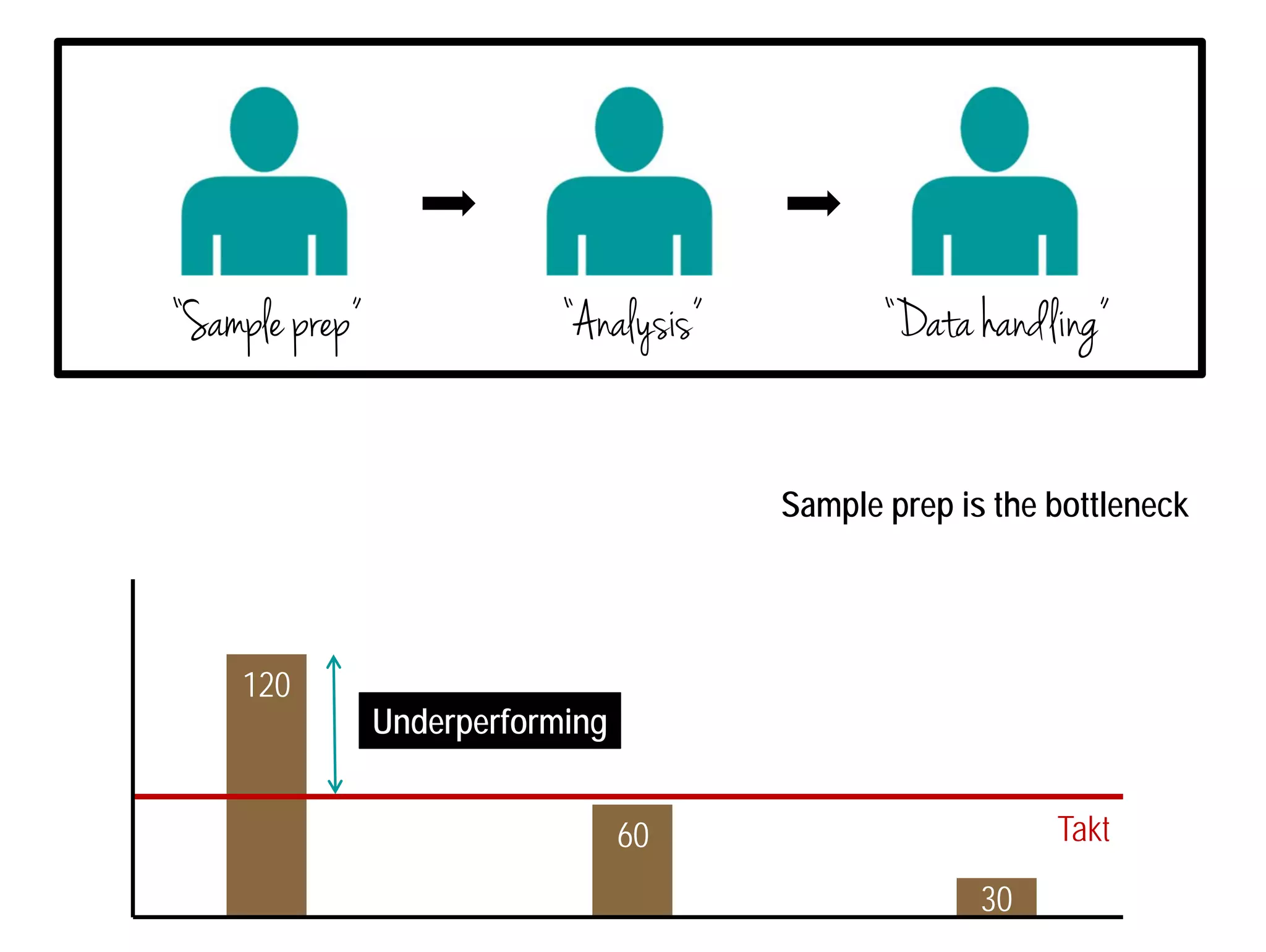

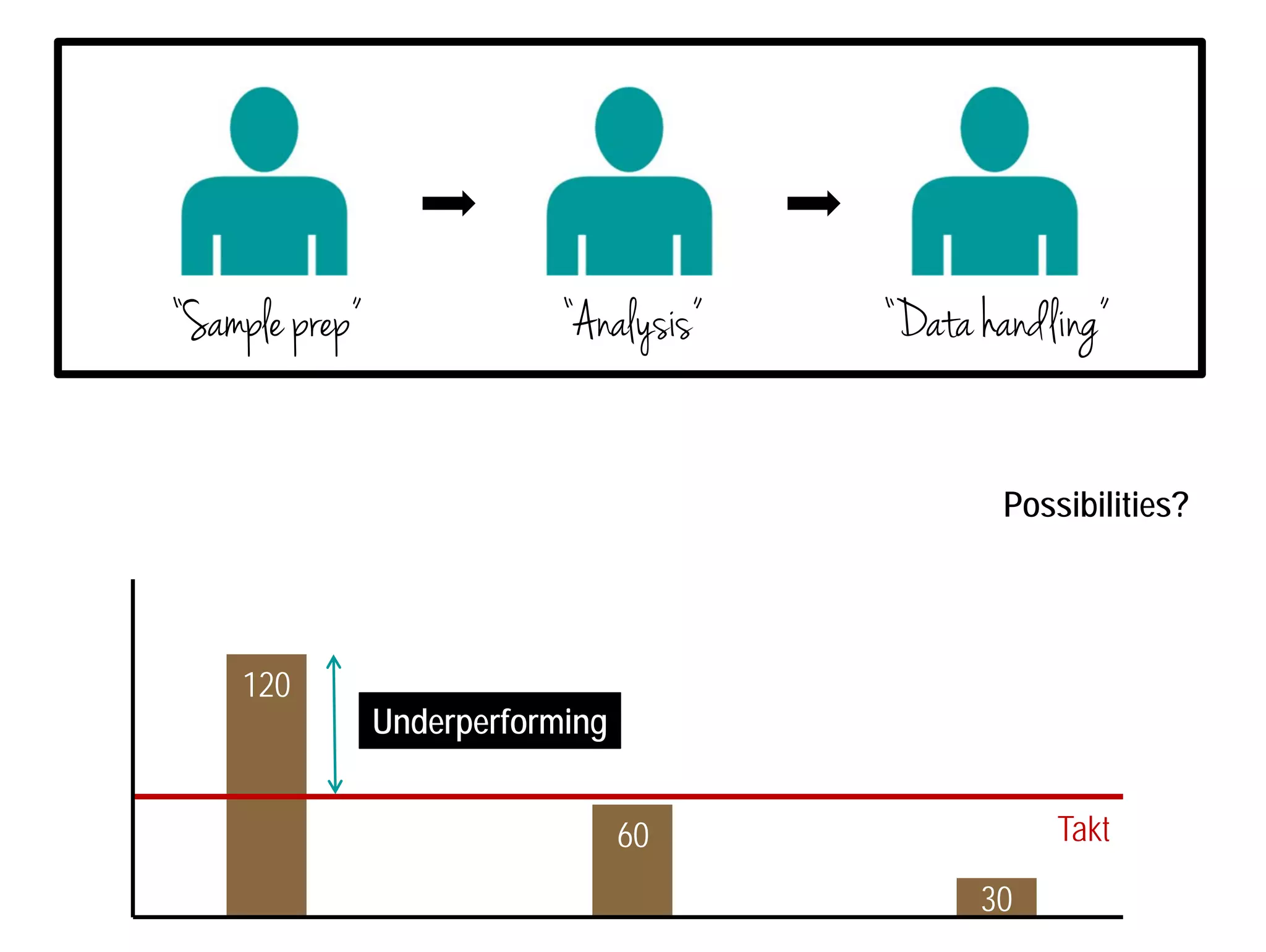

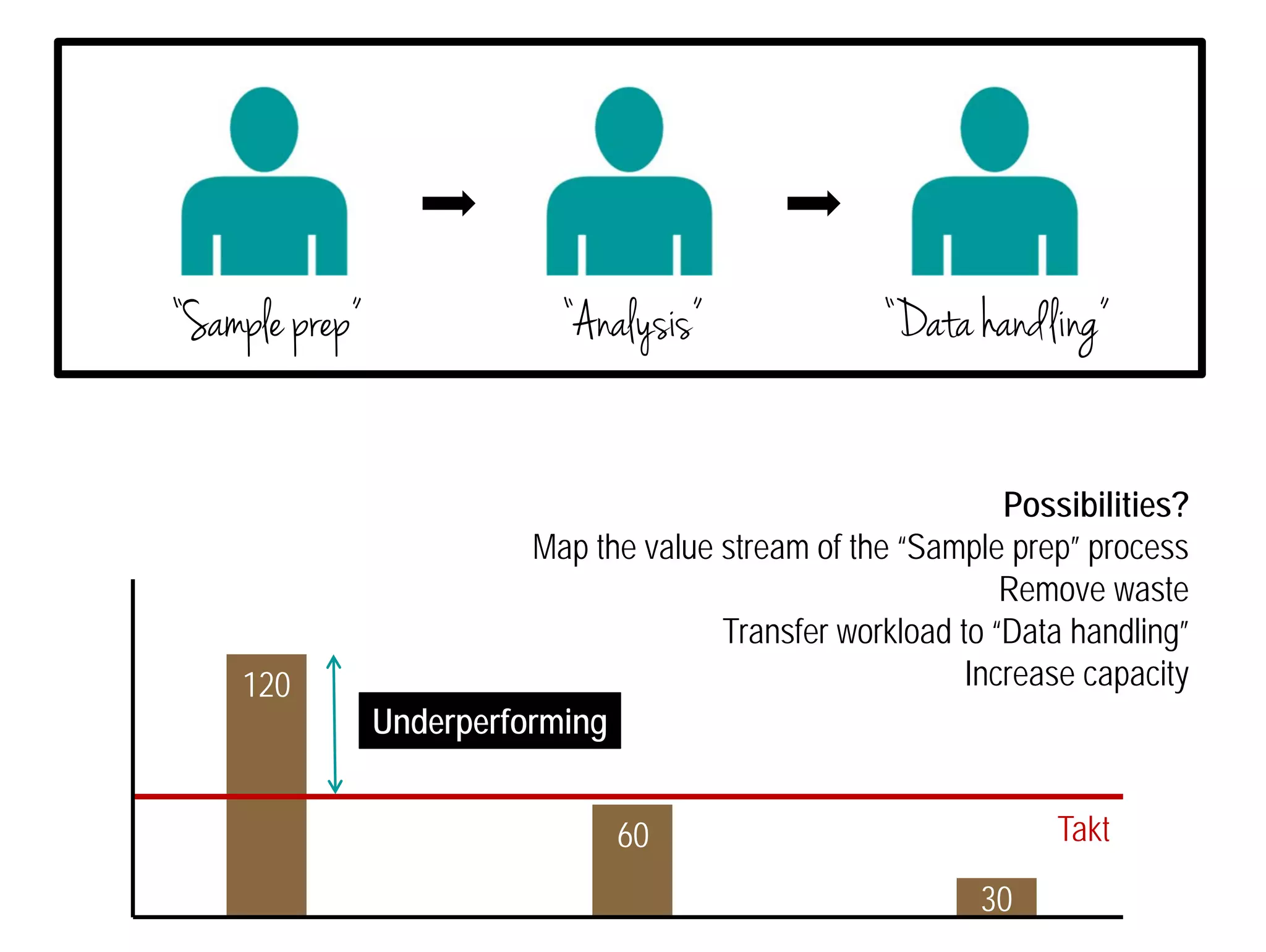

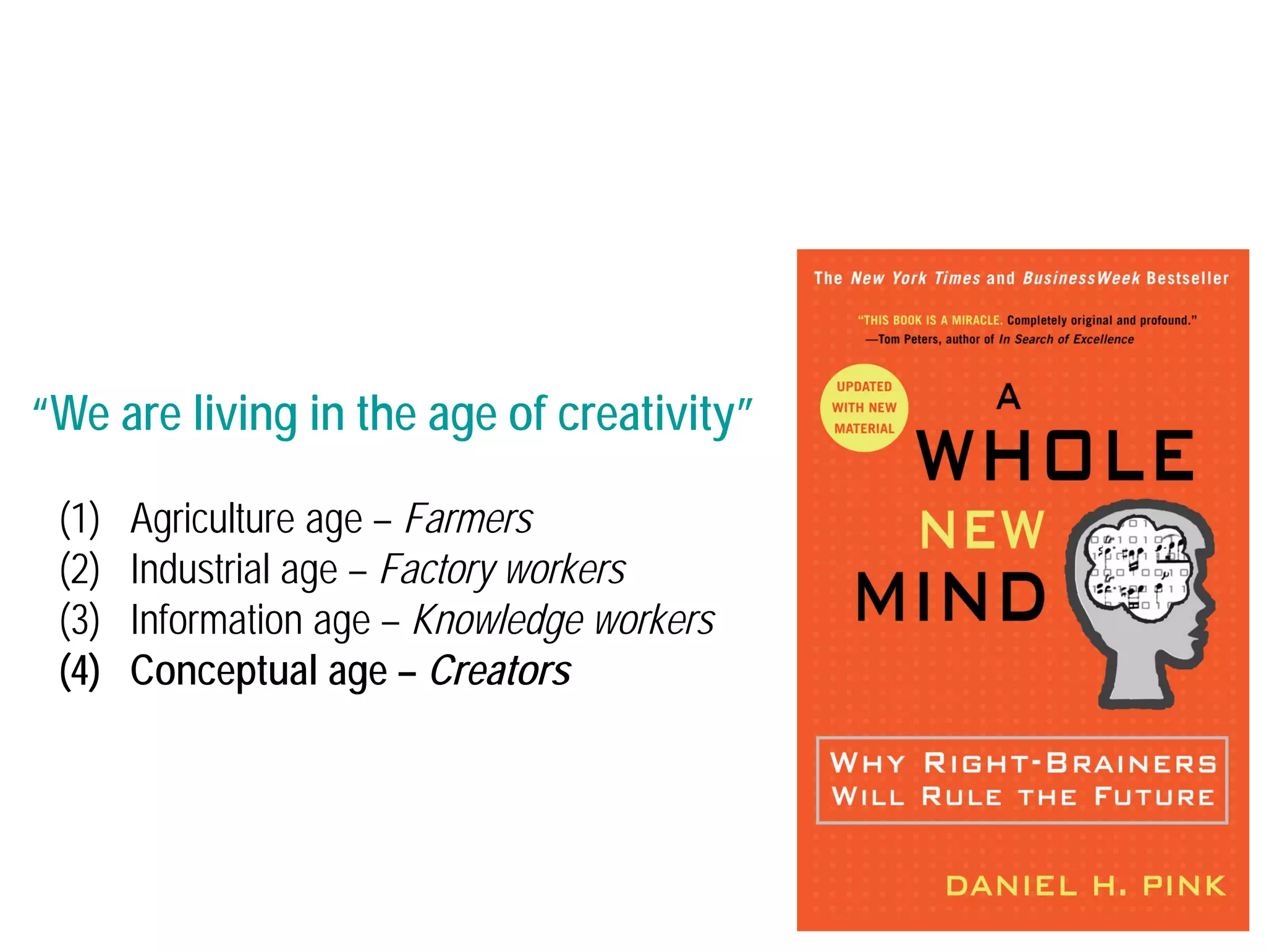

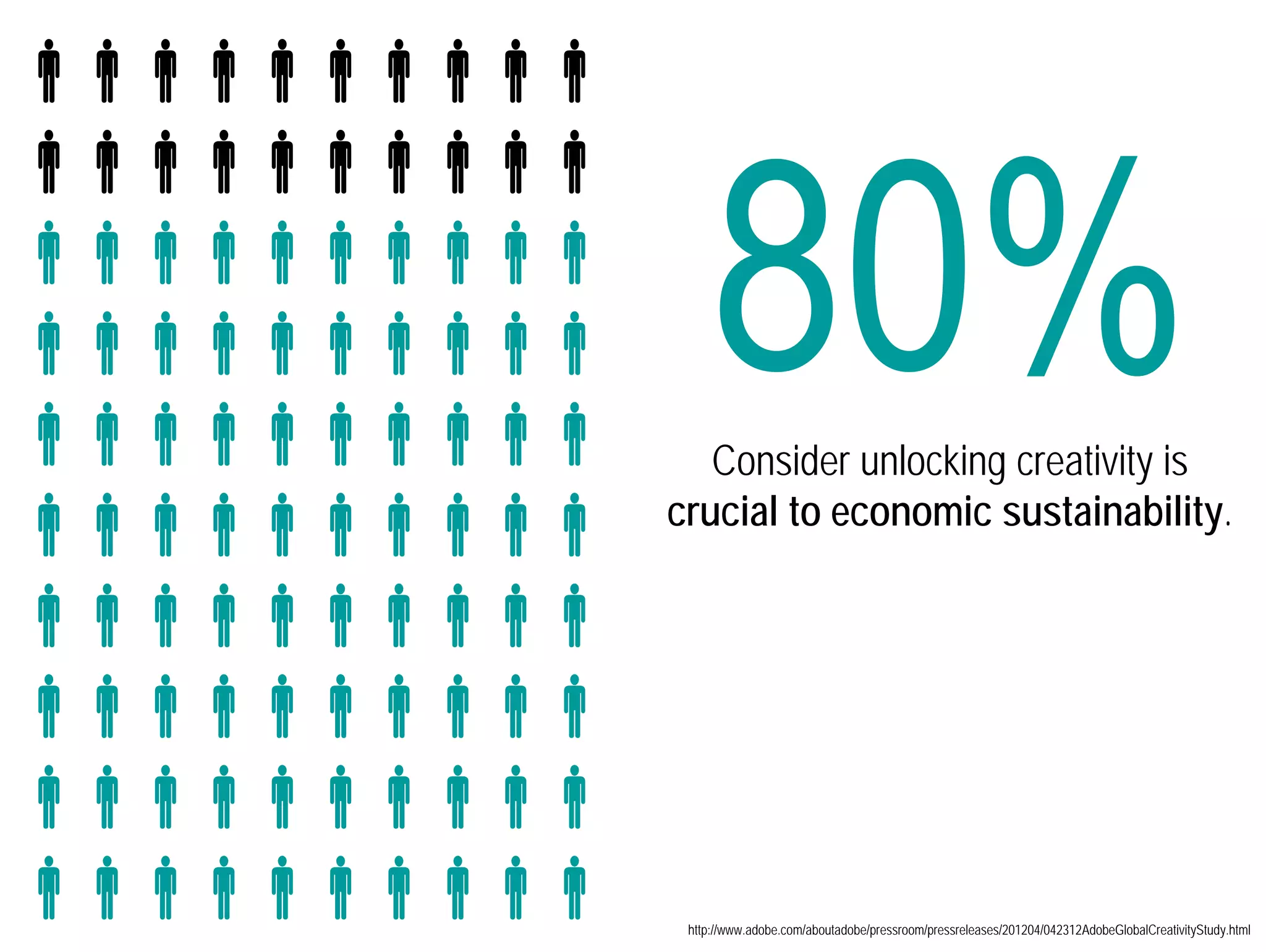

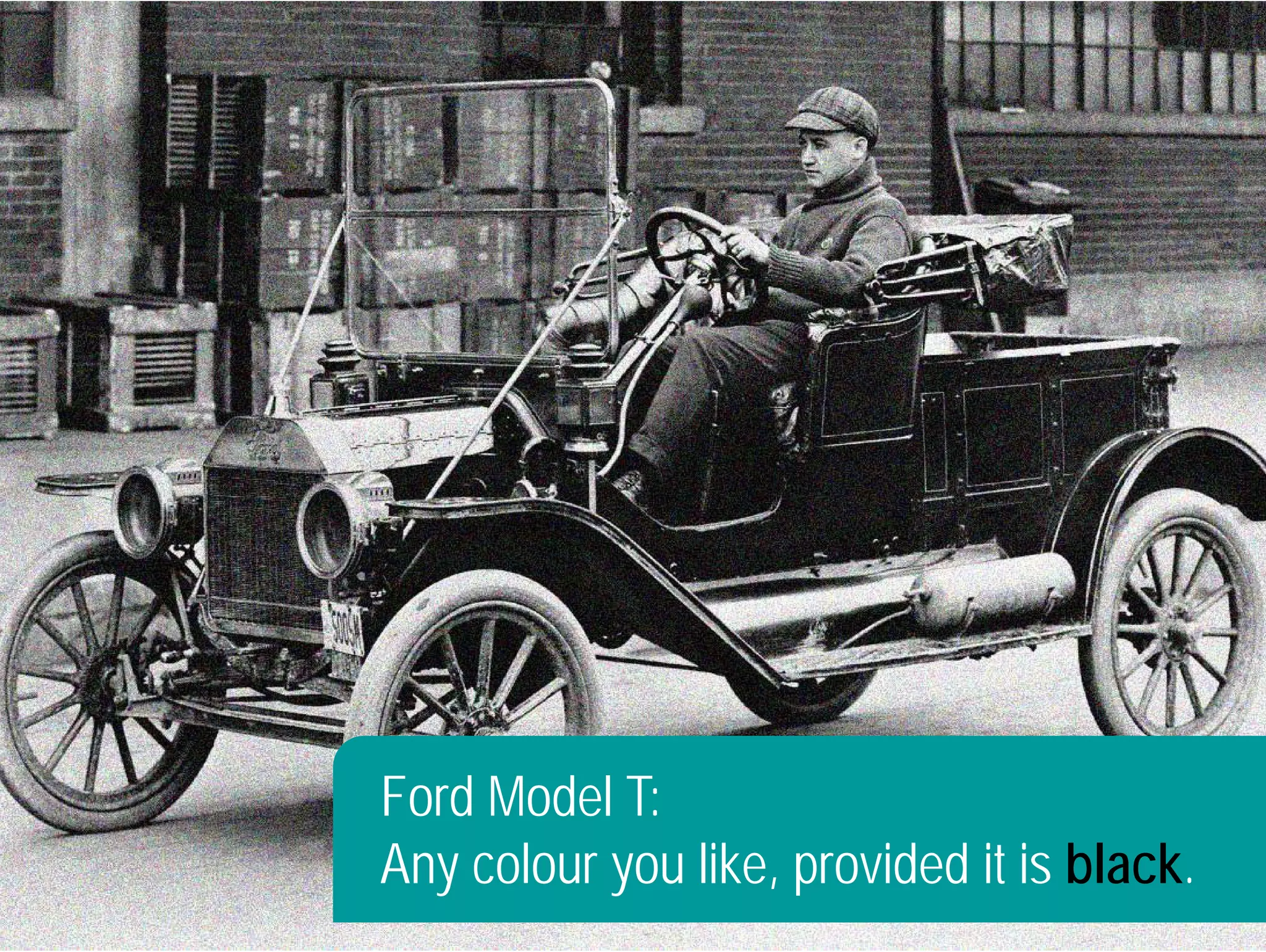

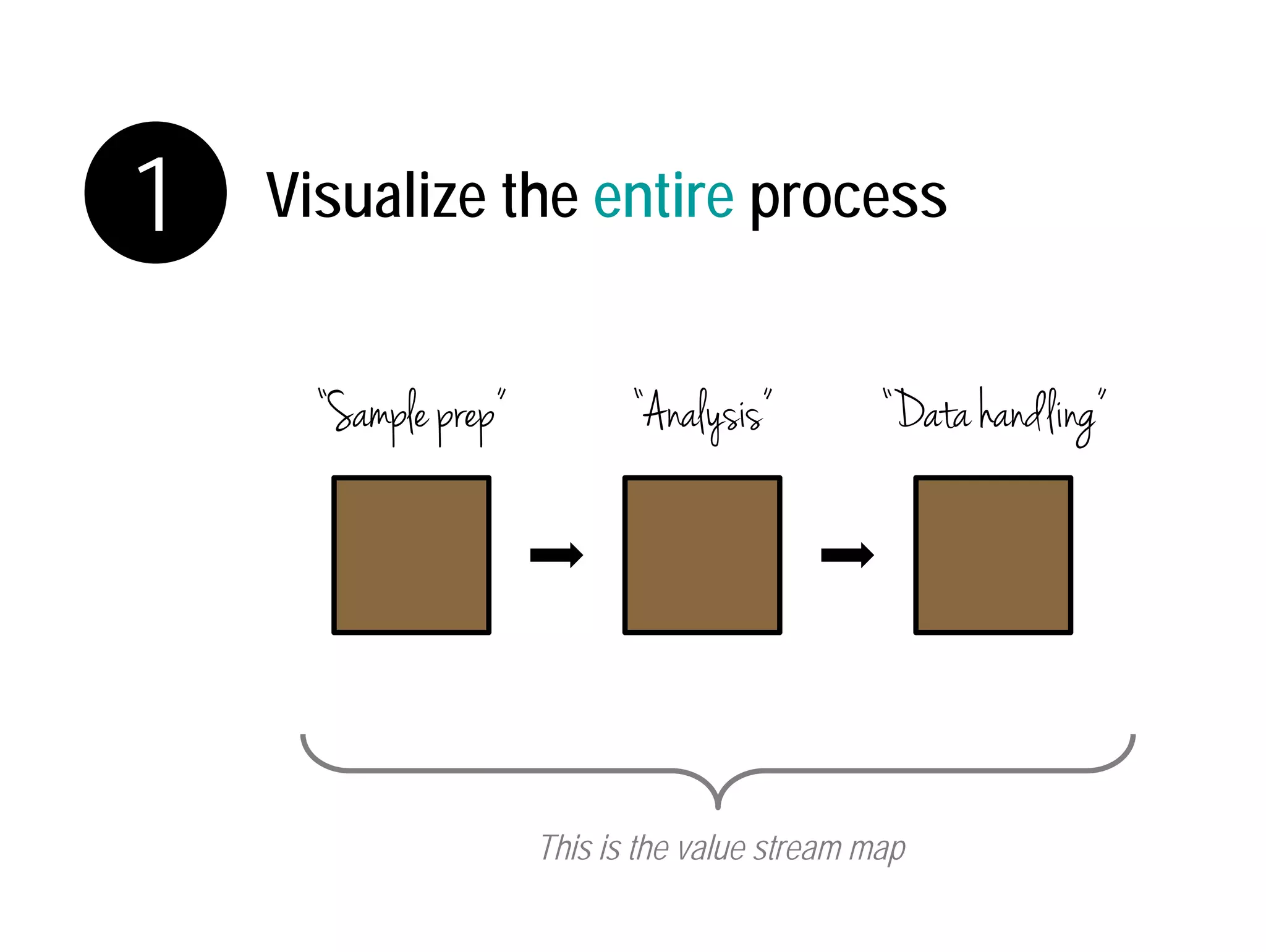

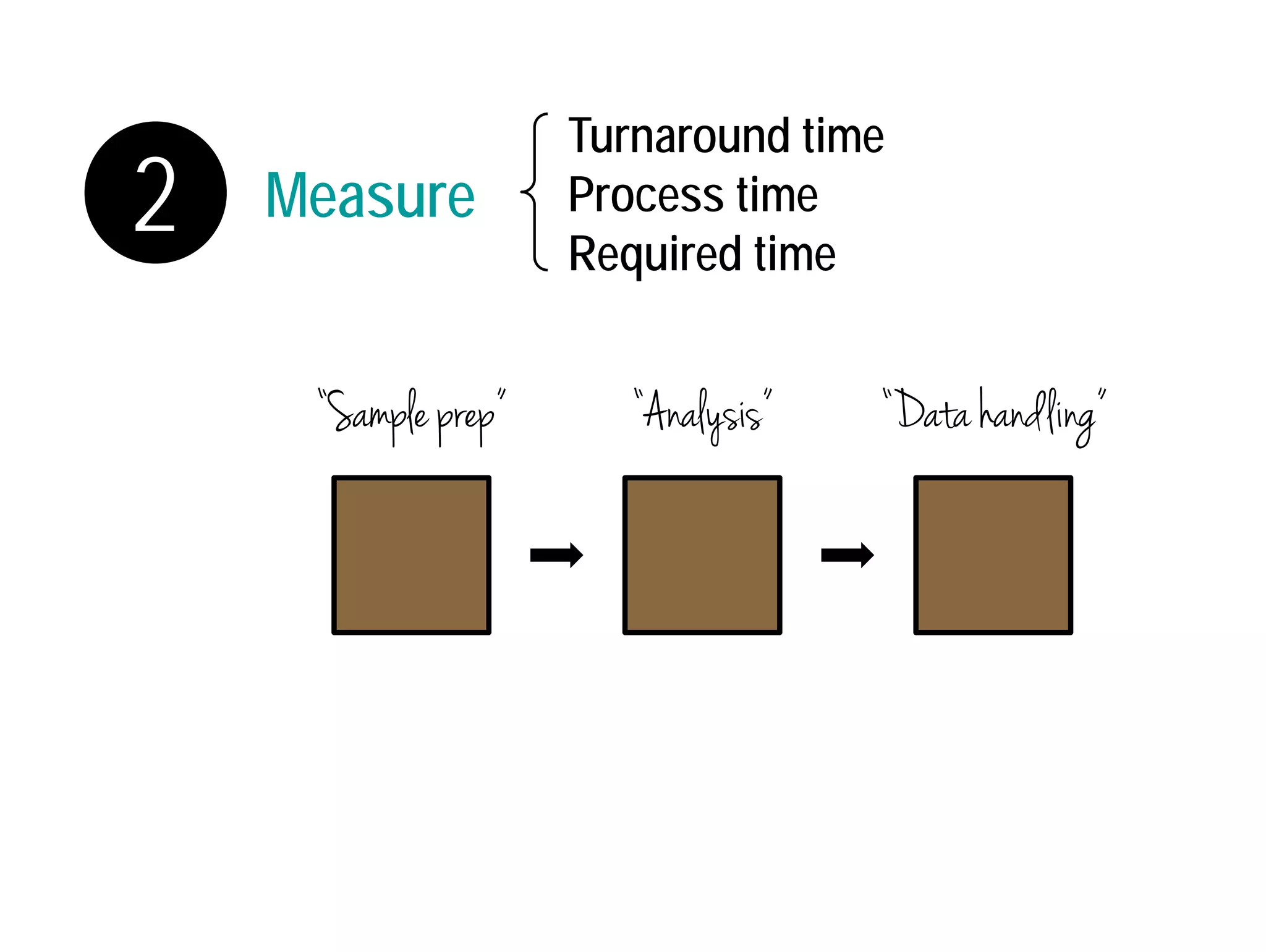

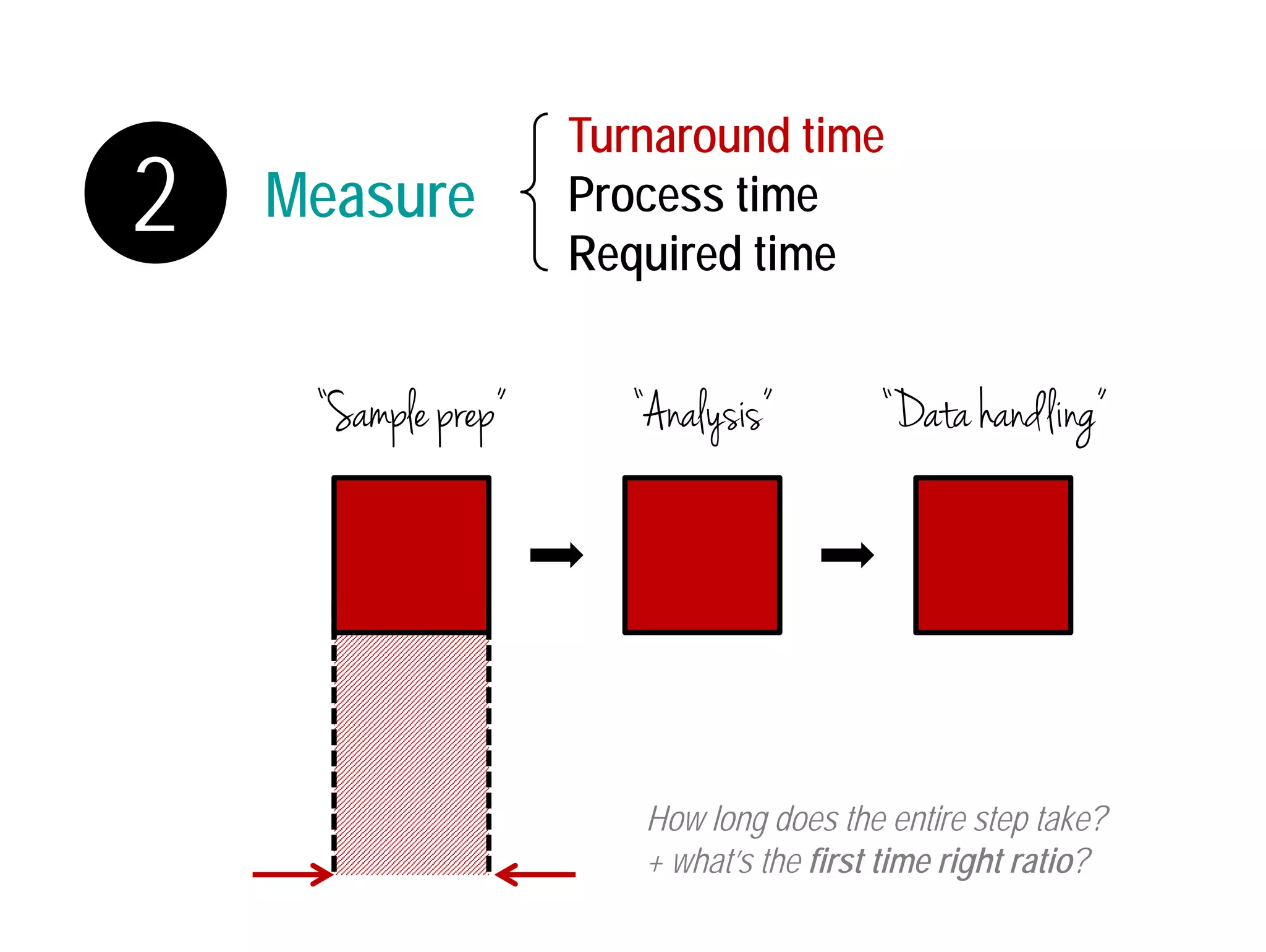

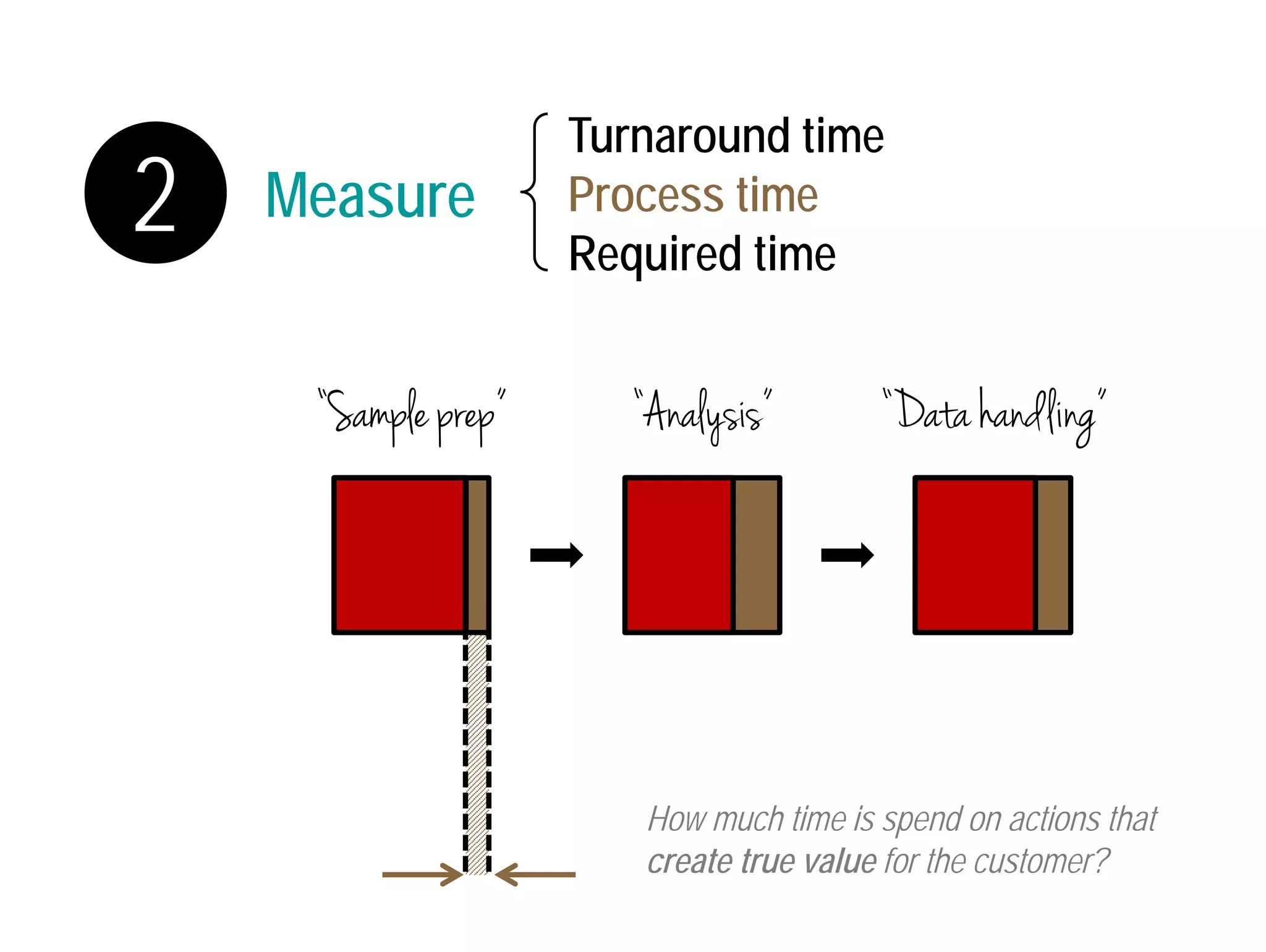

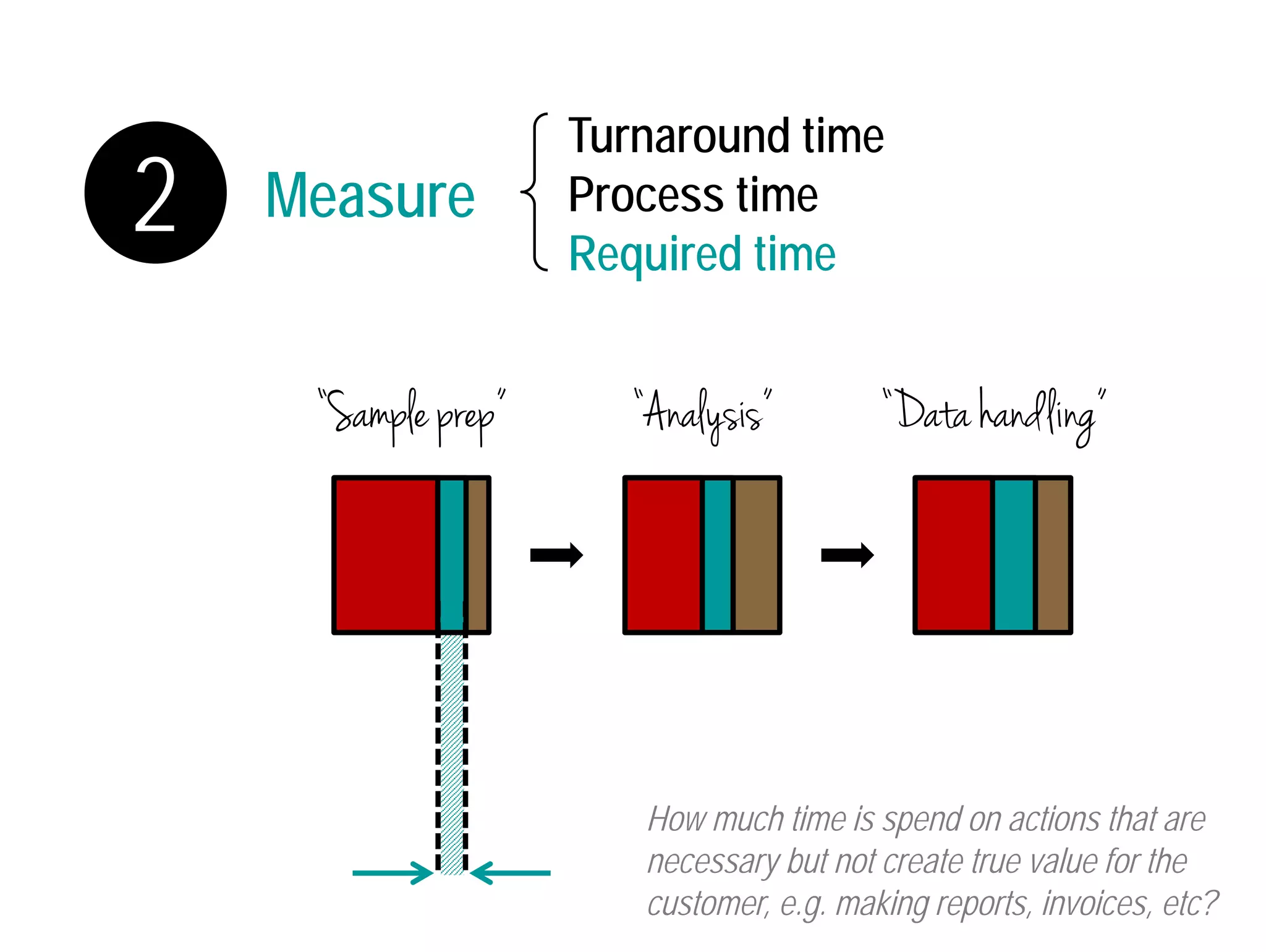

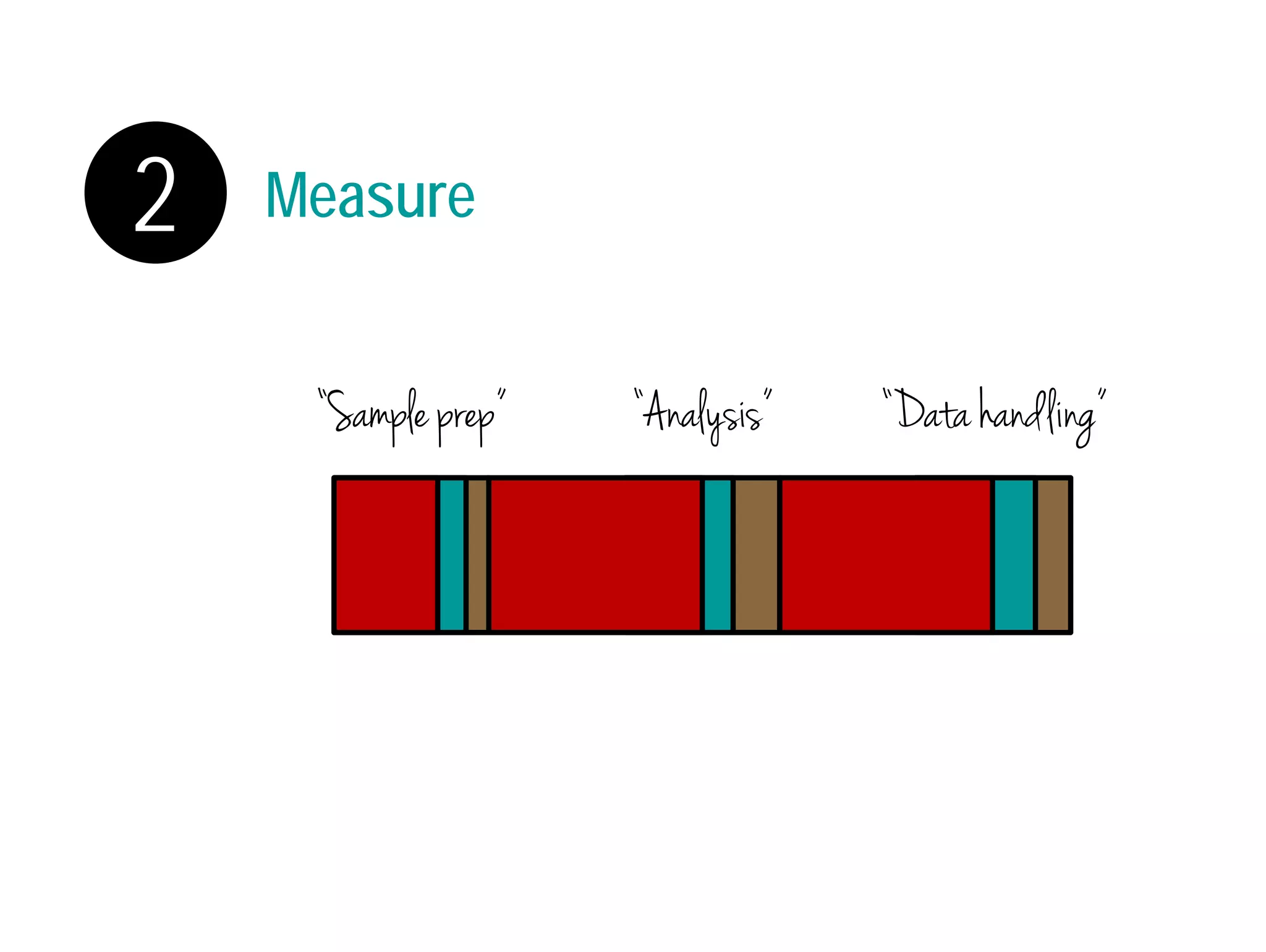

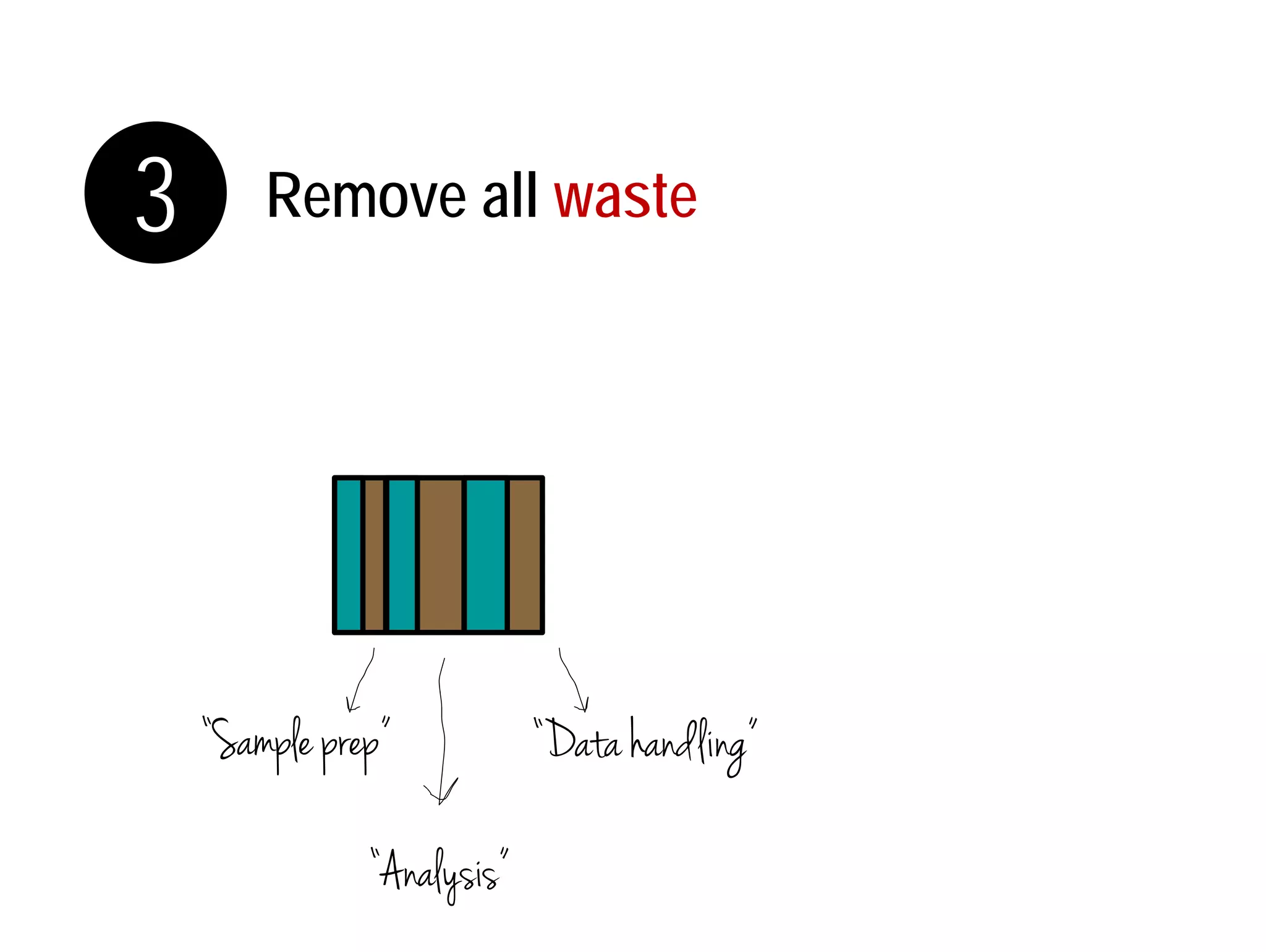

The document discusses lean innovation principles aimed at unlocking creativity for economic sustainability across various sectors by reducing waste and improving productivity. It outlines techniques such as value stream mapping, measurement of turnaround times, and the application of lean tools like PDCA, 5 Whys, and Kanban to eliminate inefficiencies. The overall goal is to systematically remove waste, ultimately enhancing the process flow and promoting effective innovation.

![[The tools]

PDCA

5 Whys

One-piece flow

Kanban

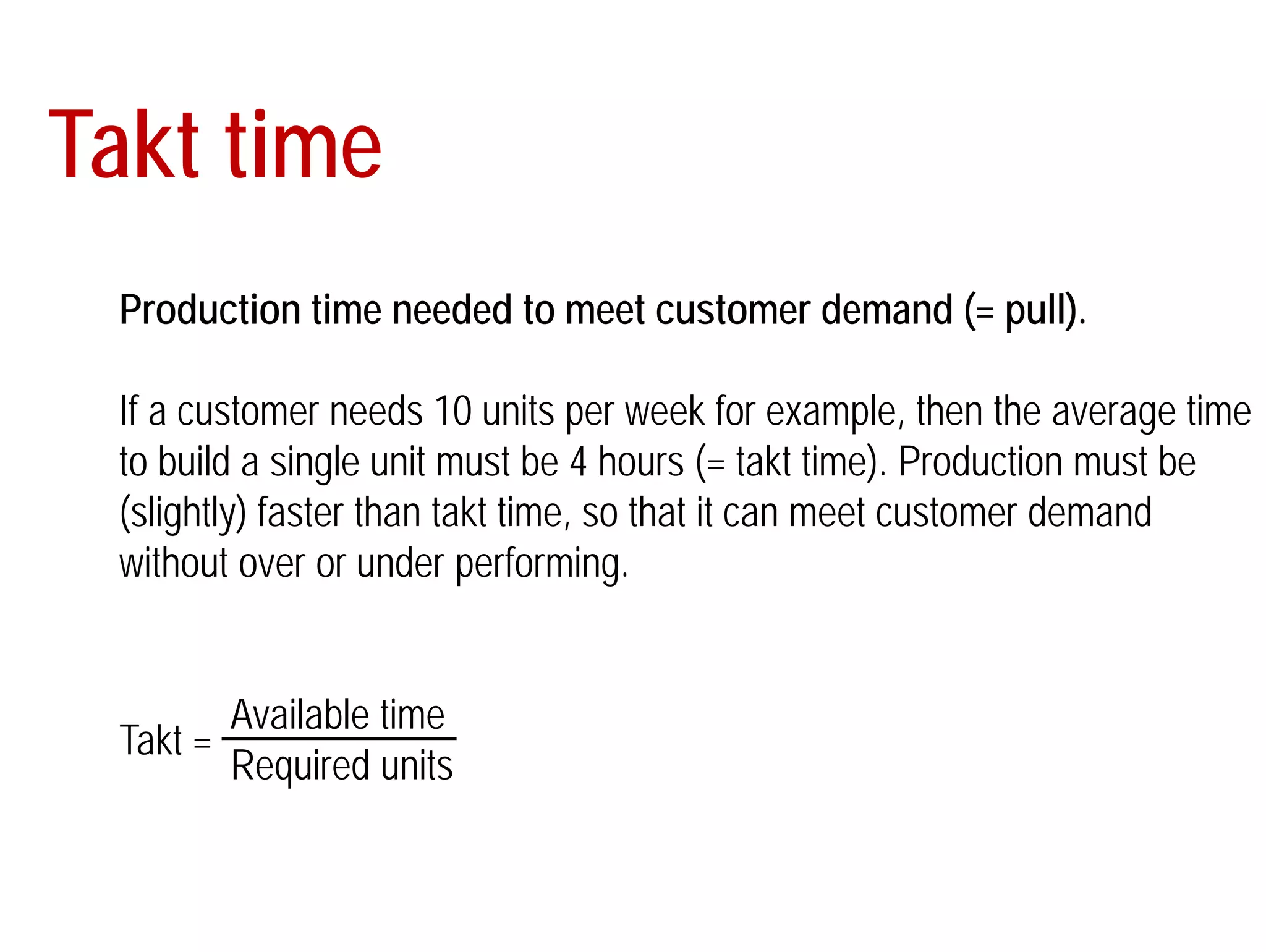

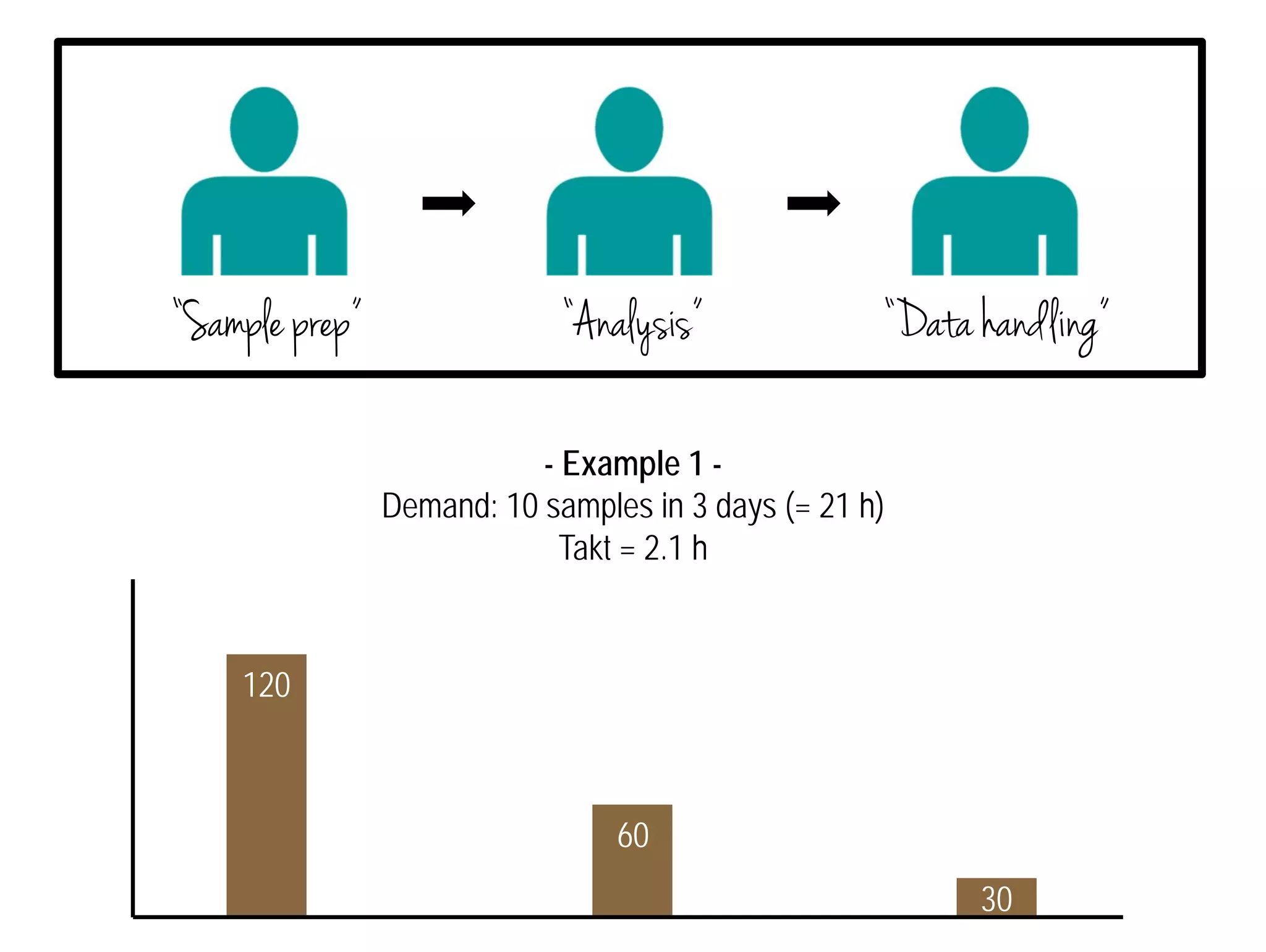

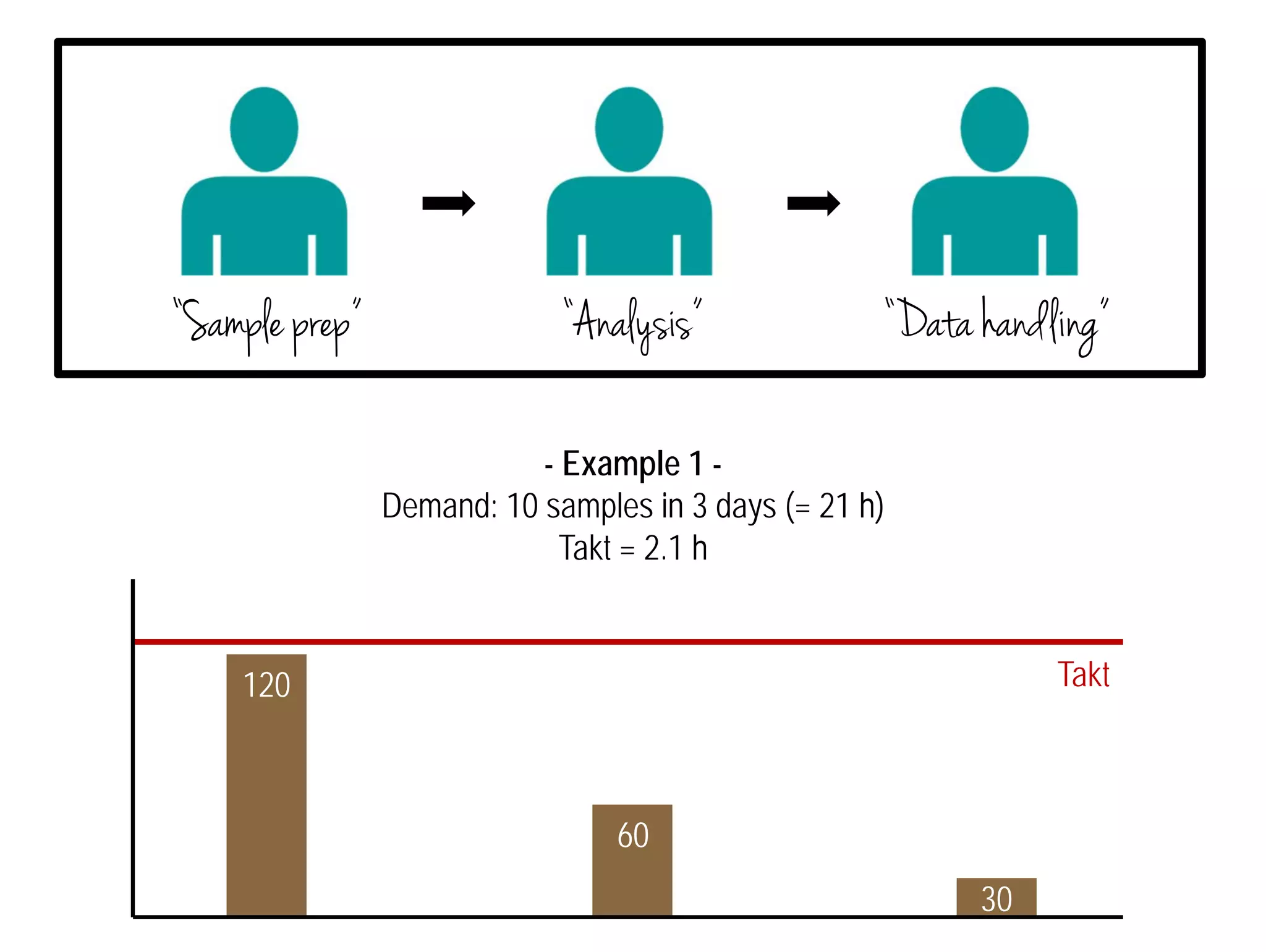

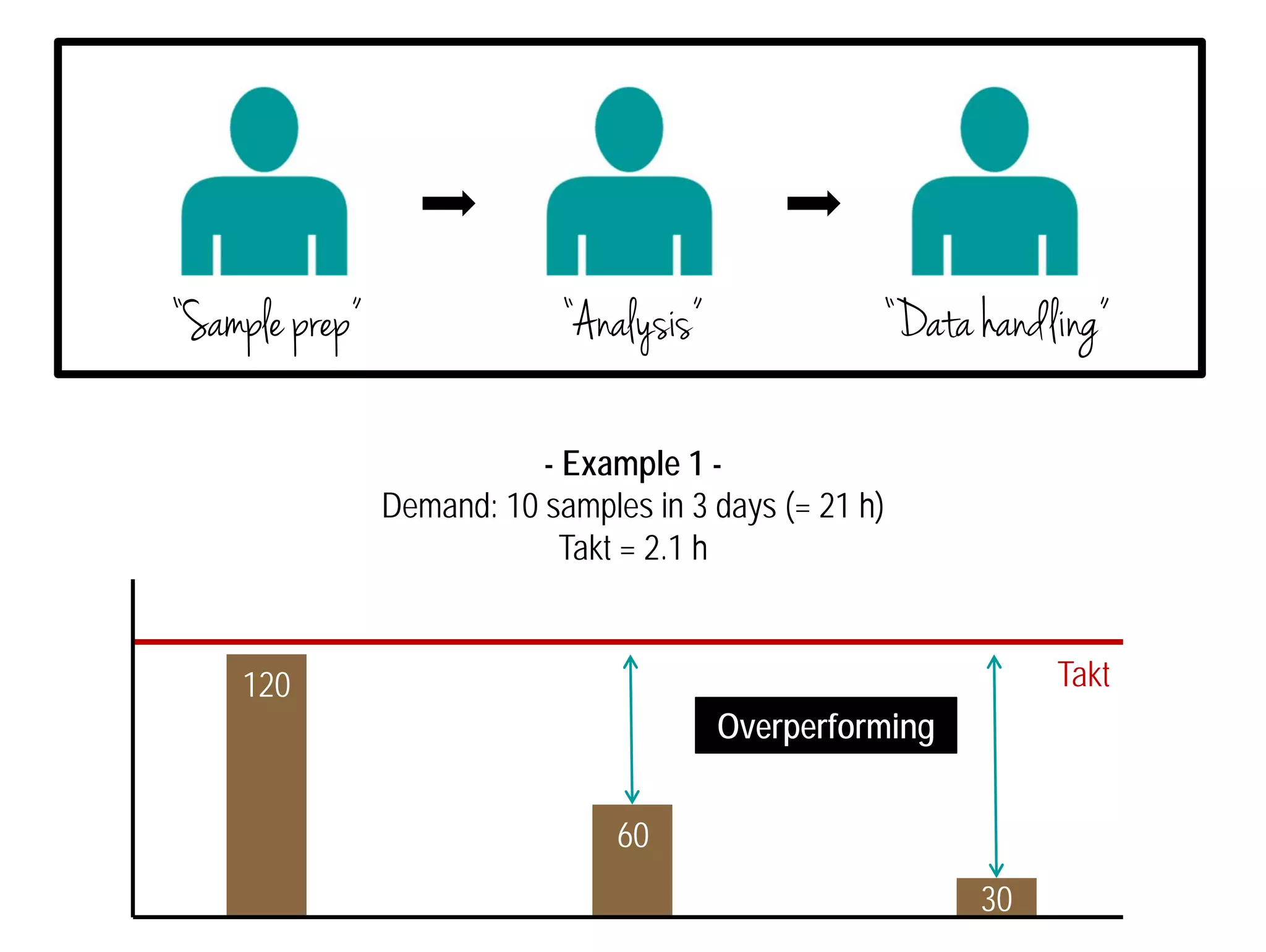

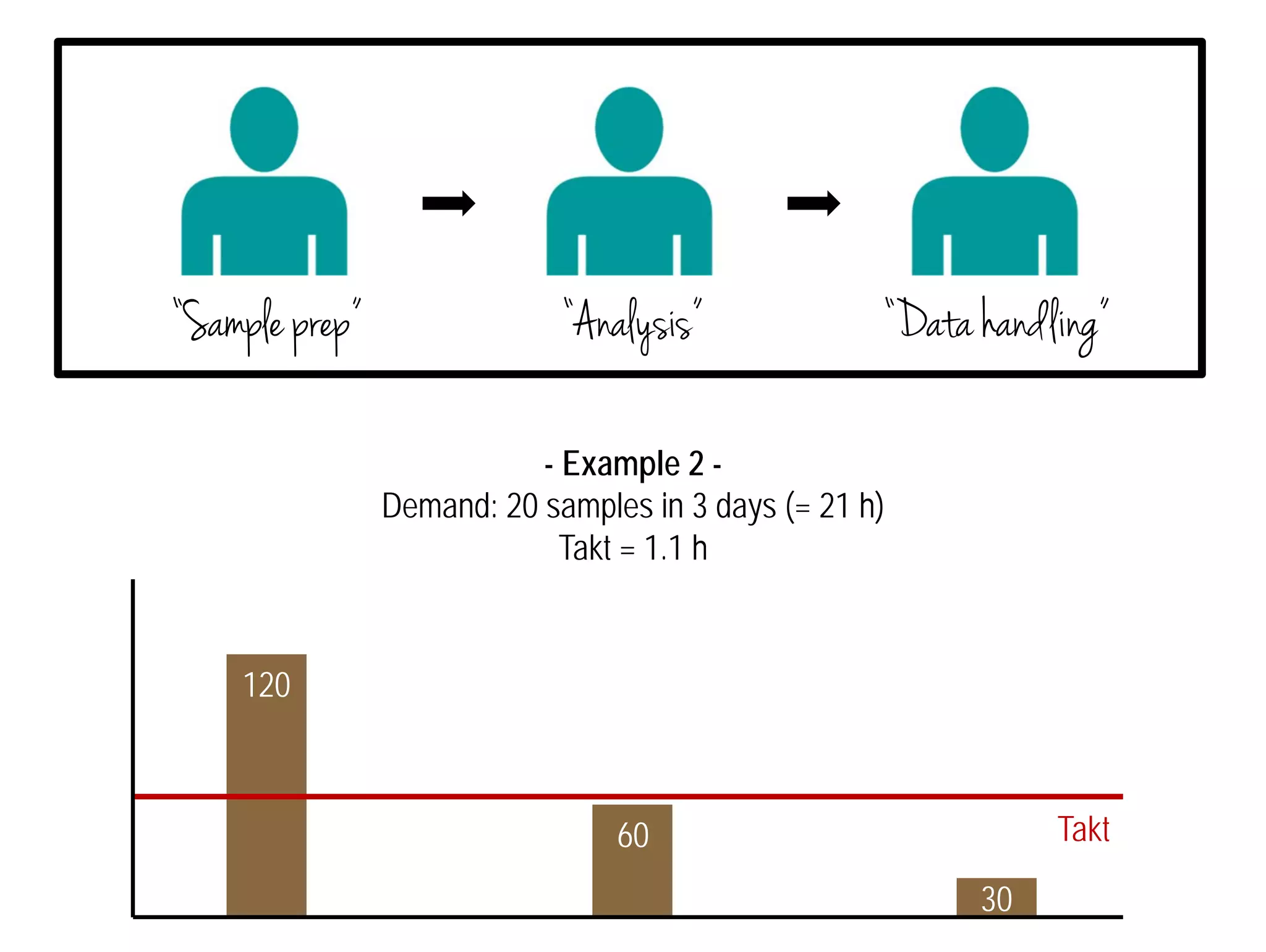

Takt time

Line balancing

5S](https://image.slidesharecdn.com/leanthinkinginresearch-140612083945-phpapp02/75/Lean-innovation-Basic-principles-of-Lean-41-2048.jpg)