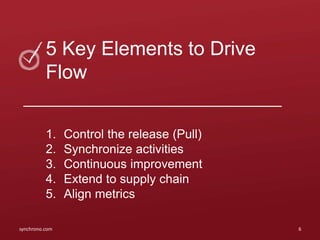

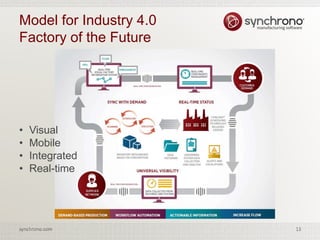

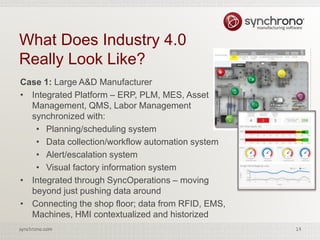

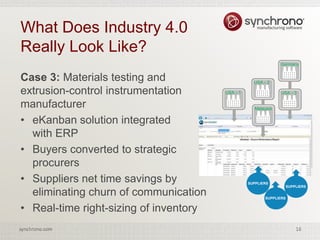

The document presents a summary of a presentation by John Maher on creating a demand-driven factory of the future, highlighting five key elements that drive flow in manufacturing: controlling release, synchronizing activities, continuous improvement, extending to the supply chain, and aligning metrics. It emphasizes the importance of technology in facilitating real-time data-driven decisions and providing an integrated view of operations within an Industry 4.0 framework. Three case studies detail practical applications of these strategies in various manufacturing contexts.