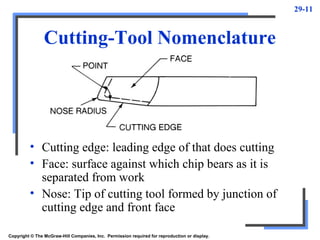

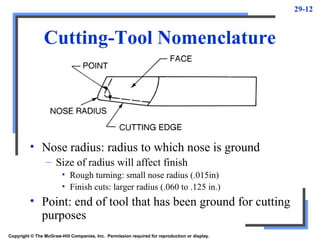

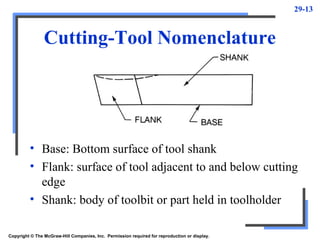

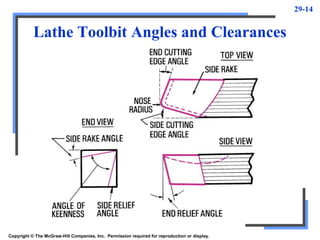

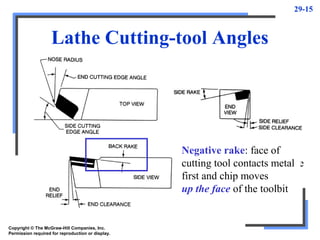

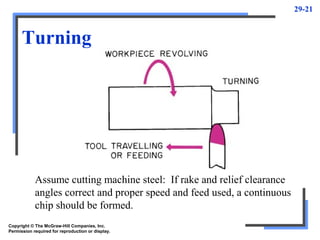

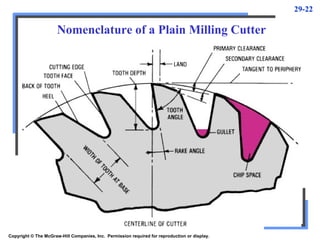

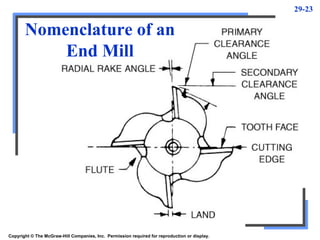

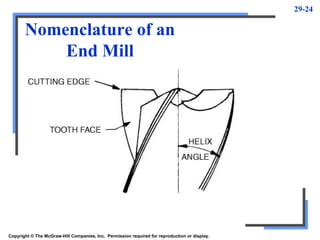

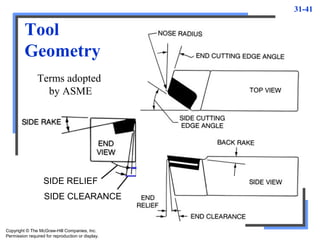

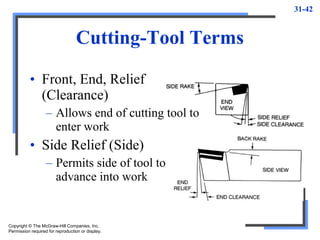

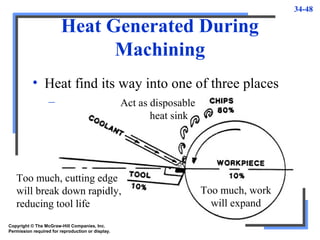

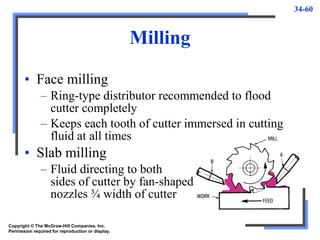

This document provides an overview of cutting tools and cutting fluids. It begins by defining the objectives of understanding cutting tool nomenclature, materials, and applications. It then describes different types of cutting tools, such as high-speed steel, cemented carbides, ceramics, and diamond toolbits. It also discusses cutting fluid types like oils, emulsifiable oils, and chemical fluids, and their functions in cooling, lubricating, and prolonging tool life during machining operations.