The document discusses different types of cutting tool materials used in machining. It describes:

1. Carbon and medium alloy steels, which are the oldest tool materials but have low hardness and wear resistance.

2. High speed steel developed in 1900, which adds alloying elements to improve hardness and heat resistance.

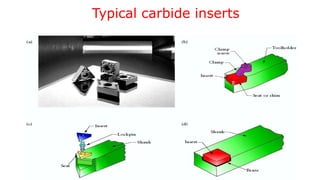

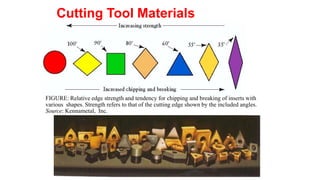

3. Cemented carbides or sintered carbides developed in 1926-1930, which are produced using powder metallurgy and provide high hardness up to 1000°C, allowing high speed machining.