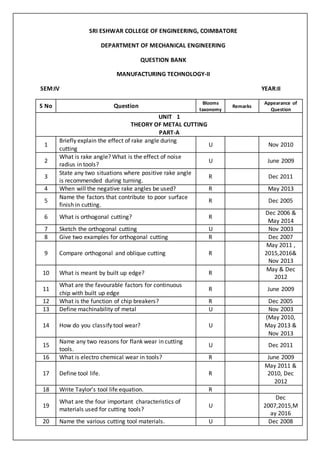

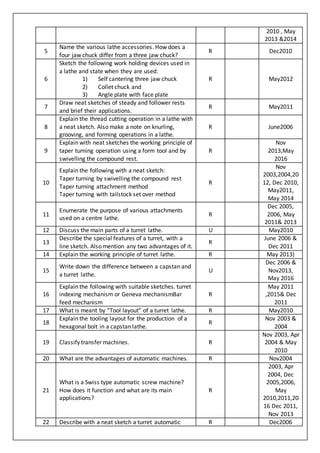

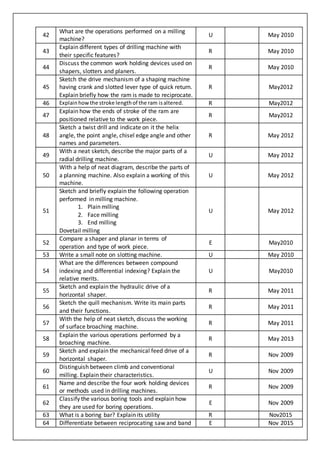

This document contains a question bank for the subject Manufacturing Technology-II from the Department of Mechanical Engineering at SRI ESHWAR College of Engineering, Coimbatore. It includes 50 questions related to the theory of metal cutting and turning machines, categorized under different units and parts. The questions cover topics like tool geometry, tool materials, machinability, tool wear, cutting forces, tool life, cutting fluids, lathe parts and operations. Multiple choice, short answer and numerical type questions have been included along with their expected difficulty level and remarks.