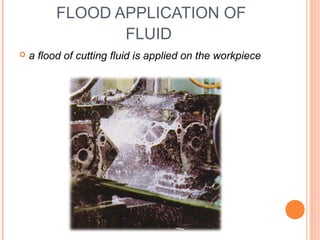

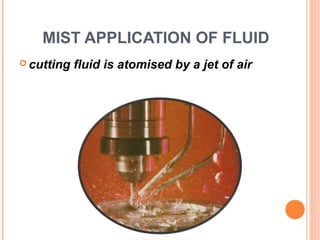

Cutting fluids are essential in machining for lubricating, cooling, and removing chips, categorized into straight oils, soluble oils, semi-synthetic fluids, and synthetic fluids. Each type serves distinct purposes with varying lubrication and cooling properties, while effective application methods include flood, jet, and mist applications. Health hazards from cutting fluid exposure, particularly skin contact, must be addressed through proper safety measures.