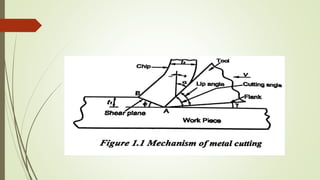

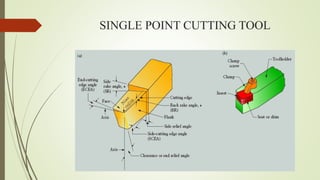

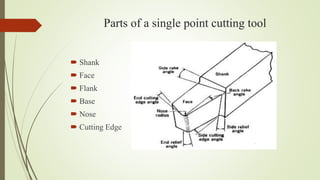

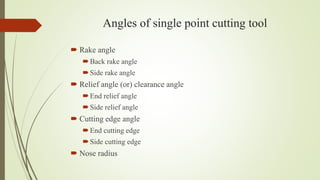

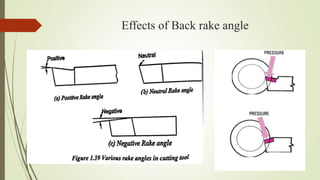

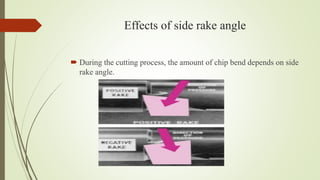

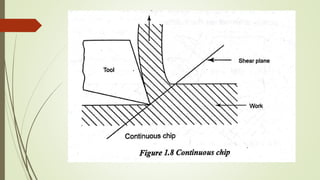

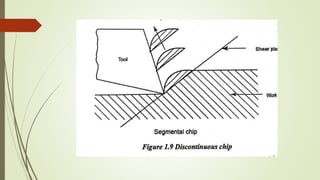

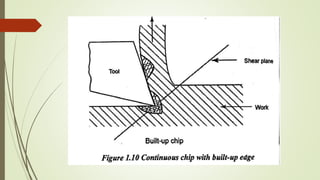

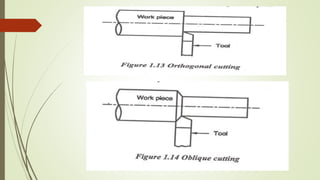

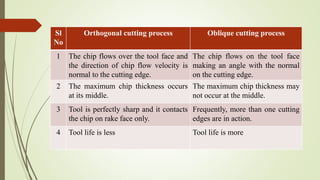

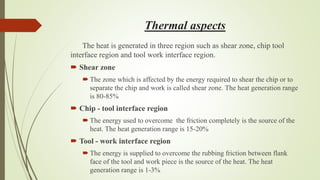

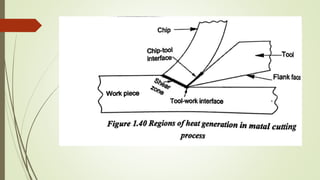

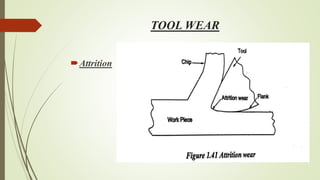

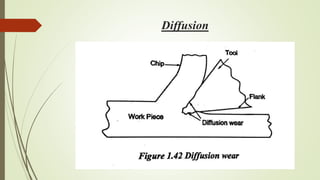

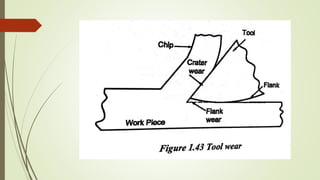

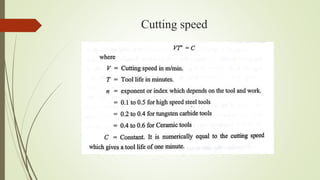

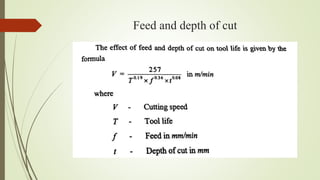

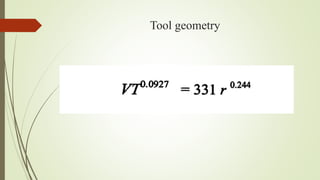

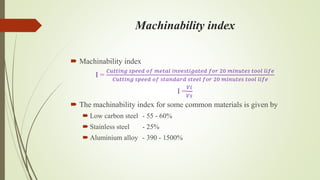

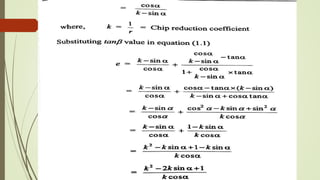

The document provides an overview of the theory of metal cutting. It discusses the mechanics of chip formation, types of chips, cutting tools and their components/angles. It also describes the metal cutting process, orthogonal vs oblique cutting, thermal aspects of cutting, tool wear and life, factors affecting surface finish and machinability. Cutting fluids, their functions and types are also summarized.