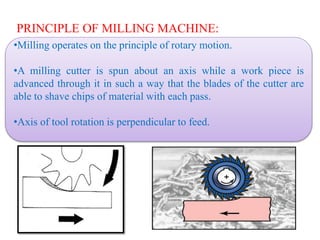

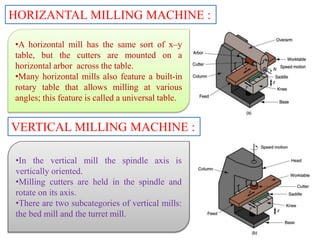

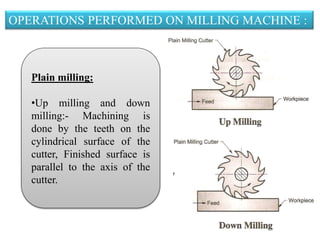

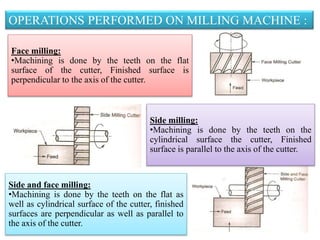

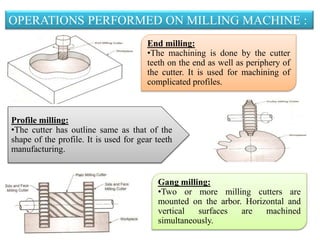

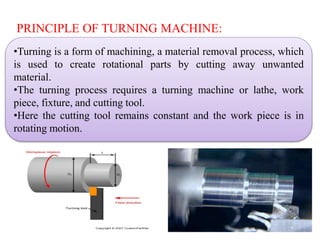

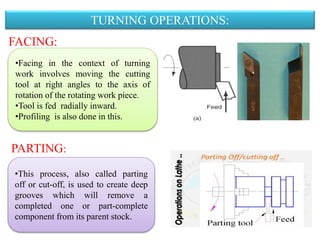

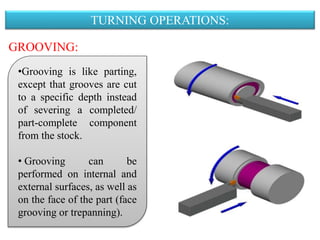

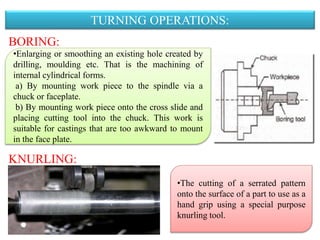

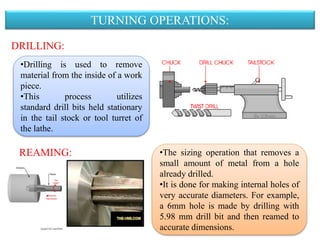

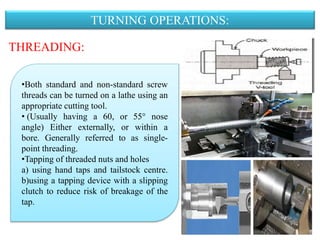

This document provides an overview of milling and turning operations. It discusses the principles and types of milling machines like horizontal and vertical mills. Common milling operations include plain, face, side, profile, end and gang milling. Turning operations covered are facing, parting, grooving, boring, knurling, drilling, reaming, threading, taper and polygonal turning. Both milling and turning remove material using rotary cutters or single point tools on workpieces mounted on machine tools.