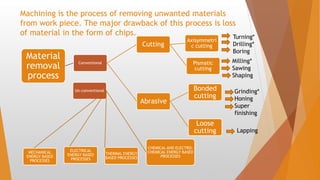

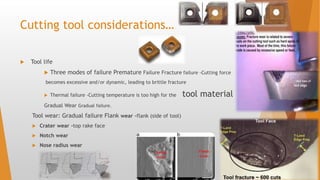

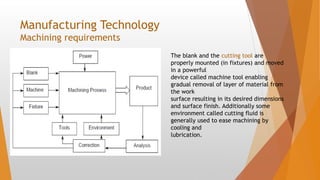

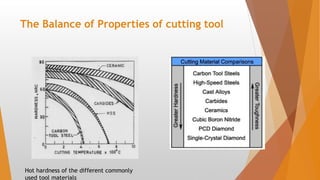

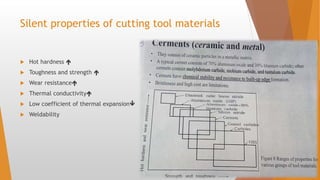

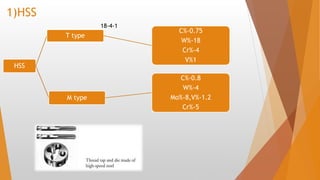

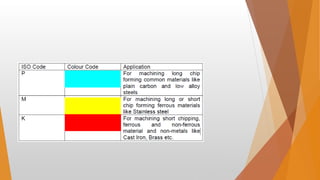

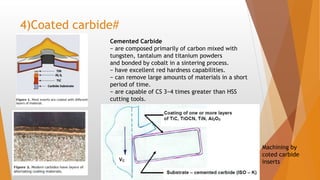

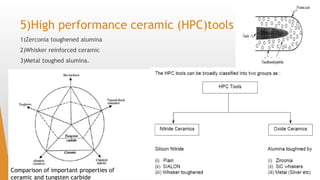

This document discusses emerging cutting tool materials that can improve machining performance. It begins by explaining that machining involves cutting tools undergoing high forces and temperatures, so tool life and geometry are important considerations. Different tool materials are then outlined, including tungsten carbide, high-speed steel, ceramics, cermets, cubic boron nitride, polycrystalline diamond, and diamond coatings. Each material has advantages like high hardness, toughness, wear resistance, or thermal conductivity suited for different machining applications. The document concludes that continuous development of new tool materials and treatments can further push the limits of cutting performance.