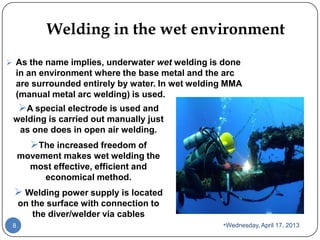

The document discusses underwater welding. It begins by explaining that underwater welding involves processes that join steel on offshore structures, pipelines, and ships underwater. It then covers the principles of underwater welding, classifications of wet and dry underwater welding, advantages and disadvantages of each method, risks and safety considerations, and applications of underwater welding such as offshore construction and ship repair. It concludes by discussing future developments in automation and new techniques like friction welding.