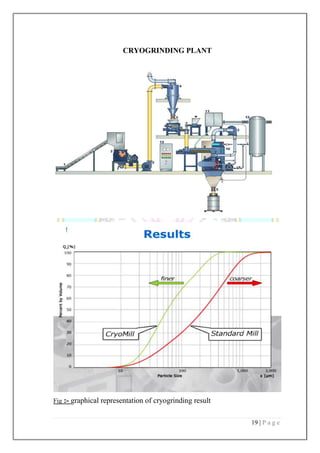

This document is a seminar report on cryogenic grinding submitted by Himanshu Tiwari to fulfill requirements for a Bachelor of Technology degree. Cryogenic grinding uses very low temperatures produced by liquid nitrogen to embrittle materials, making them easier to grind into smaller particles. Experimental studies showed cryogenic grinding of herbs resulted in 15.6% average increase in active constituents compared to normal grinding methods. Cryogenic grinding has applications in processing materials like steel, plastics, adhesives, spices and explosives due to advantages like reduced wear on equipment and ability to grind difficult composite materials.