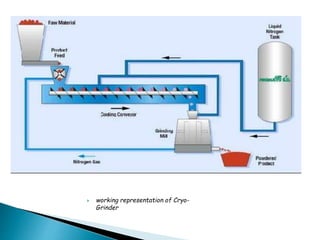

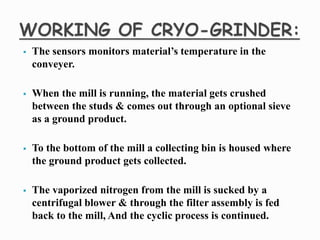

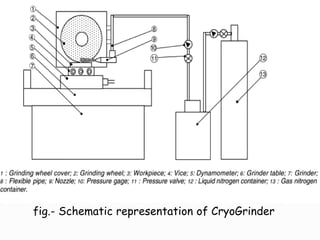

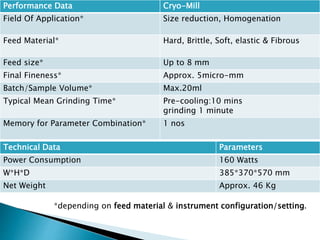

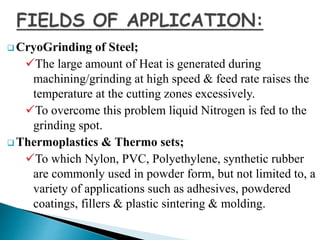

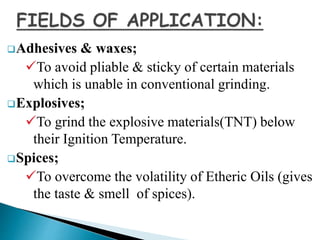

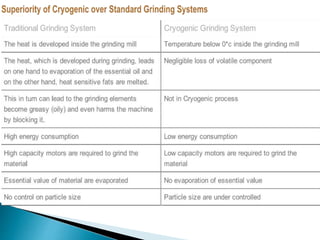

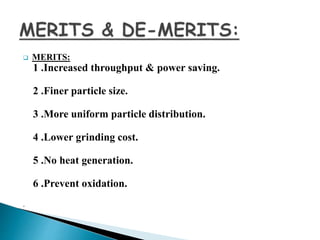

This document discusses cryogenic grinding technology. It begins with introducing cryogenics and explaining the problems with conventional grinding such as heat generation and oxidation. It then describes how cryogenic grinding works by cooling materials below their embrittlement temperature using liquid nitrogen before grinding them, resulting in brittle fracture. The key components of a cryogenic grinder and its working principle are outlined. Performance data shows cryogenic grinding can achieve a final fineness of 5 micrometers using less energy. Several applications of cryogenic grinding in industries like steel machining, plastics, adhesives, and spices are provided. The merits include increased throughput and finer particles while the demerits include high operation and maintenance costs.