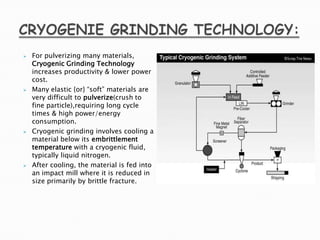

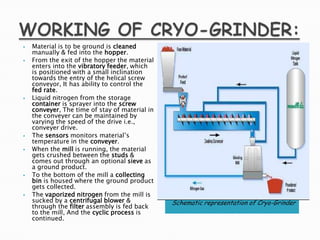

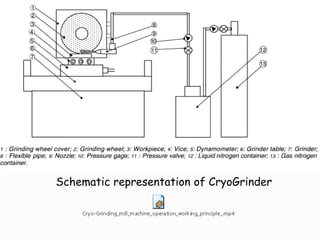

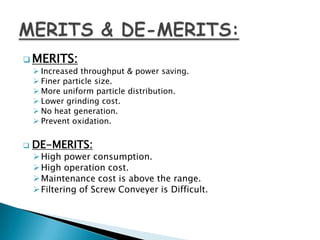

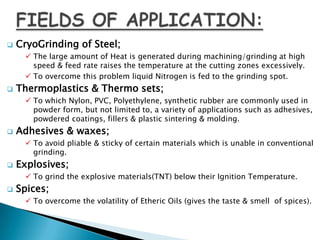

The document discusses cryogenic grinding technology. Cryogenic grinding involves cooling materials below their embrittlement temperature using liquid nitrogen before grinding them, allowing for grinding of hard, brittle, soft, elastic, and fibrous materials. It describes the working principle of cryogenic grinding, which involves spraying liquid nitrogen on materials as they are conveyed into an impact mill. Cryogenic grinding offers benefits like increased throughput, finer particle sizes, and lower grinding costs compared to conventional grinding. The document provides example applications of cryogenic grinding in industries like steel machining, plastics processing, adhesives production, explosives processing, and spices grinding.