This document provides an overview of cryogenic processes and cryogenic manufacturing. It discusses what cryogenics and cryogenic processes are, and explains that cryogenics involves producing and maintaining very low temperatures. It then describes several common cryogenic manufacturing processes like air separation, production of liquid oxygen and nitrogen, liquid carbon dioxide production, and argon gas production. Diagrams of typical cryogenic processes and plants are included. The document lists several references for further information on topics like cryogenic treatment of materials, history of cryogenics, and properties of gases produced through cryogenic processes.

![2

1. Introduction

Nowadays we have many of methods for producing materials such as fluids, and gases. So,

the Cryogenics is related to the branch of the physic science which talking about production

materials in low temperatures and their effects on them. Cryogenic have many applications by the

process of cryogenics, for example we can produce the liquid oxygen and other industrial gases.

The cryogenic region of most interest is characterized principally by five fluids: oxygen, nitrogen,

neon, hydrogen, and helium. [1]

The word of cryogenic is

derived from the Greek language where

“CRYOS” means “frost” or “cold”. The

development of cryogenics as a low

temperature science is a direct result of

attempts by 19th century scientists to

liquefy the permanent gases. One of

these scientists, Michael Faraday, had

succeeded, by 1845, in liquefying most

of the gases then known to exist. [2]

Cryogenics is efficient and has many

benefits and uses in our really life, for example when you want to preserve the foods in your

refrigerant or any place you can spraying the foods by one of the cryogenics like liquid nitrogen.

So, we know that this phenomenon is clearly visible in frozen fruit. When food is removed from a

"standard" freezer, it loses both its appearance and its quality. Cryogenic air separation is the most

cost-effective technology for larger plants and for producing very high purity oxygen and nitrogen.

[3]

Figure 2: Flow diagram of a

cryogenic air separation unit

Figure 1: Cryogenic Process Plant](https://image.slidesharecdn.com/safeenyaseenjafar-cryogenicpocess-211105145713/85/Cryogenic-Manufacturing-Process-5-320.jpg)

![3

1.1 What Cryogenics and Cryogenic Process are?

Cryogenics is defined as the science and technology that related to application of the

physic science which the production of extremely low temperatures and their effects on matter, a

definition that encompasses both the attainment of low temperatures that do not occur naturally on

Earth and the application of such temperatures to the study of nature or human industry.

Cryogenic Process: is the process of production and maintaining at very low temperatures. Also,

Cryogenic processes include liquefaction of air, oxygen, nitrogen, hydrogen and helium. [5]

1.2 What are the importance’s of cryogenic processes?

The process of the manufacturing Cryogenics is important and have many benefits for

daily life and to make longer in age of the foods. It has many applications in various sectors like

health sector (medical uses), material production, welding or cutting (such as liquified oxygen),

etc. Cryogenics is used in a variety of applications. It can be used to produce cryogenic fields for

rockets, in MRI machines that use liquid helium and require cryogenic cooling, storing large

quantities of food, special effects fog, recycling, freezing blood and tissue samples, and even

cooling superconductors. [6]

Applications of Cryogenics

1. General Applications

• Cryosurgery

• Cryoelectronics

• Cryobiology

• Cryonics

• Cryotherapy

2. Some Industrial benefits:

• Liquid oxygen is used in

welding,

• in the manufacture of steel

• For the preservation of blood,

dead bodies and medicines.

• Quick healing of wounds.

• Cooling the body parts by anesthesia.

• Transportation of Gases

3. Uses:

• For freezing the food for preservation for example by spraying of nitrogen liquids.

• Blood banking.

Figure 3: Liquid nitrogen is a good

example of a cryogenic fluid.](https://image.slidesharecdn.com/safeenyaseenjafar-cryogenicpocess-211105145713/85/Cryogenic-Manufacturing-Process-6-320.jpg)

![4

• X-ray

• Elictronics

• Electric power transmission

• Infarared sensors

• Liquid oxygen in artificial breathing in hospitals & aircrafts. [7]

Figure 4: By applying cryogenic freezing techniques, our fruits and food will safer than other

ways for eating and using.](https://image.slidesharecdn.com/safeenyaseenjafar-cryogenicpocess-211105145713/85/Cryogenic-Manufacturing-Process-7-320.jpg)

![5

2. Theory

The process of cryogenic or by another word production of materials under very low

temperature is important process to production by lesser time and faster work in these days. So, in

this section we will talk about Cryogenic Process or plants which related to it in details and with

some examples of this process like Air Separation Plant, Cryogenic Oxygen Plant, Argon gas

Production, Nitrogen Liquification. Also, we need PFD of them for more understand about the

process as well as faster for all. [8]

2.1 Cryogenic Manufacturing Process:

The separation or liquefaction of gases under process settings that may include increased

pressures but invariably involve very low temperatures is a frequent aspect of a cryogenic facility.

Many industrial cryogenic processes run at temperatures ranging from –165°C to –195°C at their

lowest point, with some going as low as –269°C. As a result, cold conservation becomes a key

aspect in the design of such systems, which are focused on extremely efficient heat exchange. A

typical cryogenic process, on the other hand, is made up of numerous components, with the

cryogenic section being just a small part of the total flow scheme. A typical cryogenic plant is seen

in Figure 1, which contains a pretreatment section, a cryogenic section, and a compressor/expander

section that provides process refrigeration. Feed compression, like in the case of air separation,

may be required in numerous instances. Another characteristic of cryogenic facilities is the use of

aluminum and stainless steel for the plant's cold sections to minimize embrittlement problems that

might arise with carbon steel. [9]

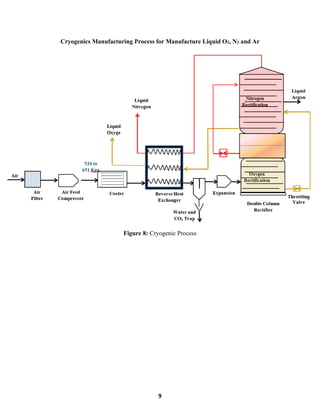

2.1.1 General Cryogenic Process of Air Separation

Air is made up of different gasses, with nitrogen and oxygen accounting for

approximately 99 percent of the entire sample volume. Dry air includes around 78 percent

nitrogen, approximately 21 percent oxygen, and approximately 0.93 percent argon by volume, as

well as traces of a variety of other gases such as hydrogen, neon, helium, krypton, xenon, and

carbon dioxide. Water vapor and other gases created by natural processes and human activities

can be found in different amounts in ambient air. The production of oxygen and nitrogen is

accomplished by an air separation process, which involves the separation of air into its

constituents. As byproducts of the air separation process, rare gases such as argon and krypton

can be recovered. [10]](https://image.slidesharecdn.com/safeenyaseenjafar-cryogenicpocess-211105145713/85/Cryogenic-Manufacturing-Process-8-320.jpg)

![6

Figure 5: Cryogenic air separation into its constituent gases involves various processes.

Combination of these processes are needed in a cryogenic air separation plant, of which the

fundamental ones are:

(a) air compression, (b) air purification, (c) heat exchanging, (d) distillation, and (e) product

compression.

2.1.2 Cryogenic Oxygen and Nitrogen Liquid Manufacturing Process

The plant of manufacturing Oxygen originally produce in air separation plant, it means

cryogenic oxygen manufacturing process is one of the facilities of industries which creates

oxygen gas. This plant is important for production of liquid oxygen for many benefits and uses

of oxygen in liquid phase in various sectors like. Medical, industrial, military, etc.

Oxygen and nitrogen products are warmed by heat exchange with the cold box feeds and

pressurized by compressors to the final delivery pressure. Alternatively, products may be

pressurized by small boost compressors. Oxygen storage may be advisable to ensure steady

gasifier operation through periods of high oxygen demand. [11]

Process Description

• Air Compressor-Low Pressure: Air is compressed at a low pressure of 5-7 bar (0.5-

0.7mpa). Air can be compressed at such low pressure by trouble free rotary compressor

(Screw/Centrifugal Type advanced technology is employed in lieu of old bulky piston

compressor).

• Pre-Cooling System: The second stage of the process uses a low-pressure refrigerant for

pre-cooling the processed air to temperature around 12o

C before it enters the purifier.

• Purification of Air by Purifier: The air enters a purifier consisting of twin Molecular

Sieve driers, working alternatively. The Molecular Sieves remove the Carbon dioxide &

moisture from the process air before the air enters Air Separation Unit.

• Cryogenic Cooling of Air By Turbo Expander: The air has to be cooled to subzero

temperatures for liquification & the cryogenic refrigeration & the cooling is provided by](https://image.slidesharecdn.com/safeenyaseenjafar-cryogenicpocess-211105145713/85/Cryogenic-Manufacturing-Process-9-320.jpg)

![7

highly efficient turbo expander, which cools the air to temperature almost below -165 to -

I 70 deg C.

• Separation if Liquid Air into Oxygen and Nitrogen by Air Separation Column: Oil

free, moisture free and Carbon Dioxide free air enters into low pressure plate fin type

Heat exchanger where the air is cooled below subzero temperatures by air expansion

process in the turbo expander. Due to the excellent thermal efficiency, we can achieve a

temperature difference delta t as low as 2 deg c at the warm end of these exchangers. Air

gets liquefied when it enters the air separation column & gets separated into oxygen &

nitrogen by the process of rectification. Liquid nitrogen is available at the outlet at purity

of 99.9% to 99.99% or 3ppm as required. Nitrogen gas is available as required.

• Final Product Liquid Nitrogen: The final product in the form liquid nitrogen to fill in

cryogenic liquid tanks for storage. [12]

Figure 6: Above diagram shows the process of manufacturing of cryogenic liquids (N2 and O2)](https://image.slidesharecdn.com/safeenyaseenjafar-cryogenicpocess-211105145713/85/Cryogenic-Manufacturing-Process-10-320.jpg)

![8

2.1.3 Liquid Carbon Dioxide (CO2) Production

Liquid CO2 is often accessible as a byproduct from major refineries and chemical

facilities and is transported by truck to its final destination. Long distances, inconsistent supply,

logistical issues, or just not accessible, then installing a stand-alone CO2-Production Plant to

manufacture your own food grade CO2 locally is an obvious obstacle. When utilizing the proper

grade of plant, such an in-house CO2 Manufacture Plant will be a significant help in overcoming

CO2 shortages, as it will always be supplied on time and at a very low price. There are several

essential elements to consider in order to keep CO2 production costs as low as feasible, and CO2

quality must match

international quality

standards. [13]

Figure 7: Liquid CO2

production plant.

2.1.4 Manufacture of Argon (Ar):

Argon is a chemical element in the eighteen group of the periodic table. It is a noble gas

and it is the third most abundant gas in earth’s atmosphere. Argon was suspected to be present in

air by Henry Cavendish in the year 1785. Fractional distillation is used in the commercial

extraction of argon from liquid air in a cryogenic air separation unit. When nitrogen gas in the

atmosphere is heated with hot calcium or magnesium, a nitride is produced, with a trace of argon

remaining as an impurity. It can also be obtained as a byproduct of natural gas purification.

Properties of Argon:

• It is odorless, colorless gas that is totally inert into other substance.

• Under extreme conditions, argon can form certain compounds even though it is a gas.

• It is characterized by same solubility level in water as that of oxygen.

• It has low thermal conductivity. [14]](https://image.slidesharecdn.com/safeenyaseenjafar-cryogenicpocess-211105145713/85/Cryogenic-Manufacturing-Process-11-320.jpg)

![10

3. List of References

1. Timmermans, K.D. and Flynn, T.M. (1989). Cryogenic Process

Engineering. [eBook] New York: Plenum Press, pages(605). Available at:

Cryogenic Process Engineering - Klaus D. Timmerhaus, Thomas M. Flynn -

Google Books [Accessed 7 Oct. 2021].

2. Controlled Thermal Processing. (n.d.). History of Cryogenics | CTP Cryogenics. [online]

Available at: https://ctpcryogenics.com/cryogenics/what-is-cryogenic-processing/history-

of-cryogenics/ [Accessed 9 Oct. 2021].

3. www.process-cooling.com. (n.d.). Cryogenic Air Separation and Liquefier Systems.

[online] Available at: https://www.process-cooling.com/articles/84579-cryogenic-air-

separation-and-liquefier-systems [Accessed 9 Oct. 2021].

4. trc.nist.gov. (n.d.). About Cryogenics. [online] Available at:

https://trc.nist.gov/cryogenics/aboutCryogenics.html. [Accessed 8 Oct.

2021].

5. America, C.S. of, Ellyn, I. 800 R.R.S. 312-C. G. and Fax: 1-630-790-3095, I.

60137 U.P. 1-630-686-8889 (n.d.). Cryogenic Treatment of Materials. [online]

Cryogenic Society of America. Available at:

https://cryogenicsociety.org/resources/cryo_central/cryogenic_treatment_of

_materials/ [Accessed 9 Oct. 2021].

6. AZoNano (2018). What are Cryogenics? [online] AZoNano.com. Available at:

https://www.azonano.com/article.aspx?ArticleID=5091 [Accessed 9 Oct.

2021].

7. Controlled Thermal Processing. (2020). How Cryogenic Processing Makes

Carbide End Mills BetterHow Cryogenic Fluids Work | CTP Cryogenics. [online]

Available at: https://ctpcryogenics.com/how-cryogenic-fluids-work/ [Accessed

9 Oct. 2021].

8. www.sciencedirect.com. (n.d.). Cryogenic Separation - an overview |

ScienceDirect Topics. [online] Available at:

https://www.sciencedirect.com/topics/engineering/cryogenic-separation.

[Accessed 9 Oct. 2021].

9. Cryogenics | physics | Britannica. (2019). In: Encyclopædia Britannica. [online]

Available at: https://www.britannica.com/science/cryogenics. [Accessed 9

Oct. 2021].](https://image.slidesharecdn.com/safeenyaseenjafar-cryogenicpocess-211105145713/85/Cryogenic-Manufacturing-Process-13-320.jpg)

![11

10. Anon, (n.d.). Cryogenic Process of Air Separation – IspatGuru. [online]

Available at: https://www.ispatguru.com/cryogenic-process-of-air-separation/

[Accessed 8 Oct. 2021].

11. Oxygen Plants. (2021). How Does Cryogenic Oxygen Plant Work

Process? [online] Available at: https://www.oxygen-plants.com/blog/how-

does-cryogenic-oxygen-plant-work/ [Accessed 8 Oct. 2021].

12. www.universalboschi.com. (n.d.). Tonnage Liquid/Gas Oxygen & Nitrogen

Plant - UNIVERSAL BOSCHI. [online] Available at:

https://www.universalboschi.com/tonnage-asu-plants.php [Accessed 8 Oct.

2021].

13. GmbH, V. (n.d.). co2 vaporiser,co2 recovery plant manufacturers,co2 recovery

plant manufacturers. [online] www.comtecswiss.com. Available at:

http://www.comtecswiss.com/en/equipment-and-plants/co2-production-

plant/ [Accessed 9 Oct. 2021].

14. AZoM (2012). Argon (Ar) - Discovery, Occurrence, Production, Properties and

Applications of Argon. [online] AZoM.com. Available at:

https://www.azom.com/article.aspx?ArticleID=7906. [Accessed 8 Oct. 2021].](https://image.slidesharecdn.com/safeenyaseenjafar-cryogenicpocess-211105145713/85/Cryogenic-Manufacturing-Process-14-320.jpg)