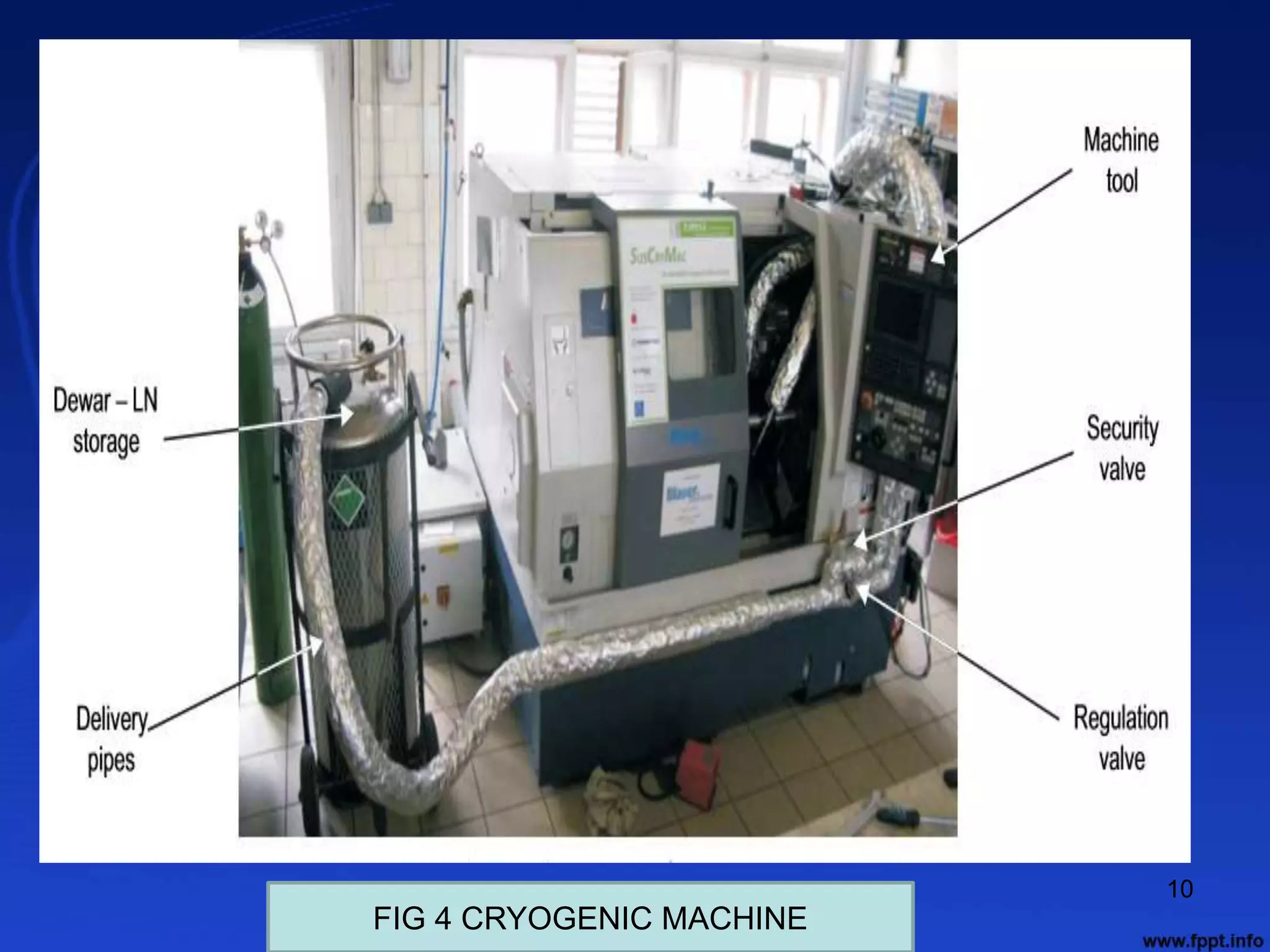

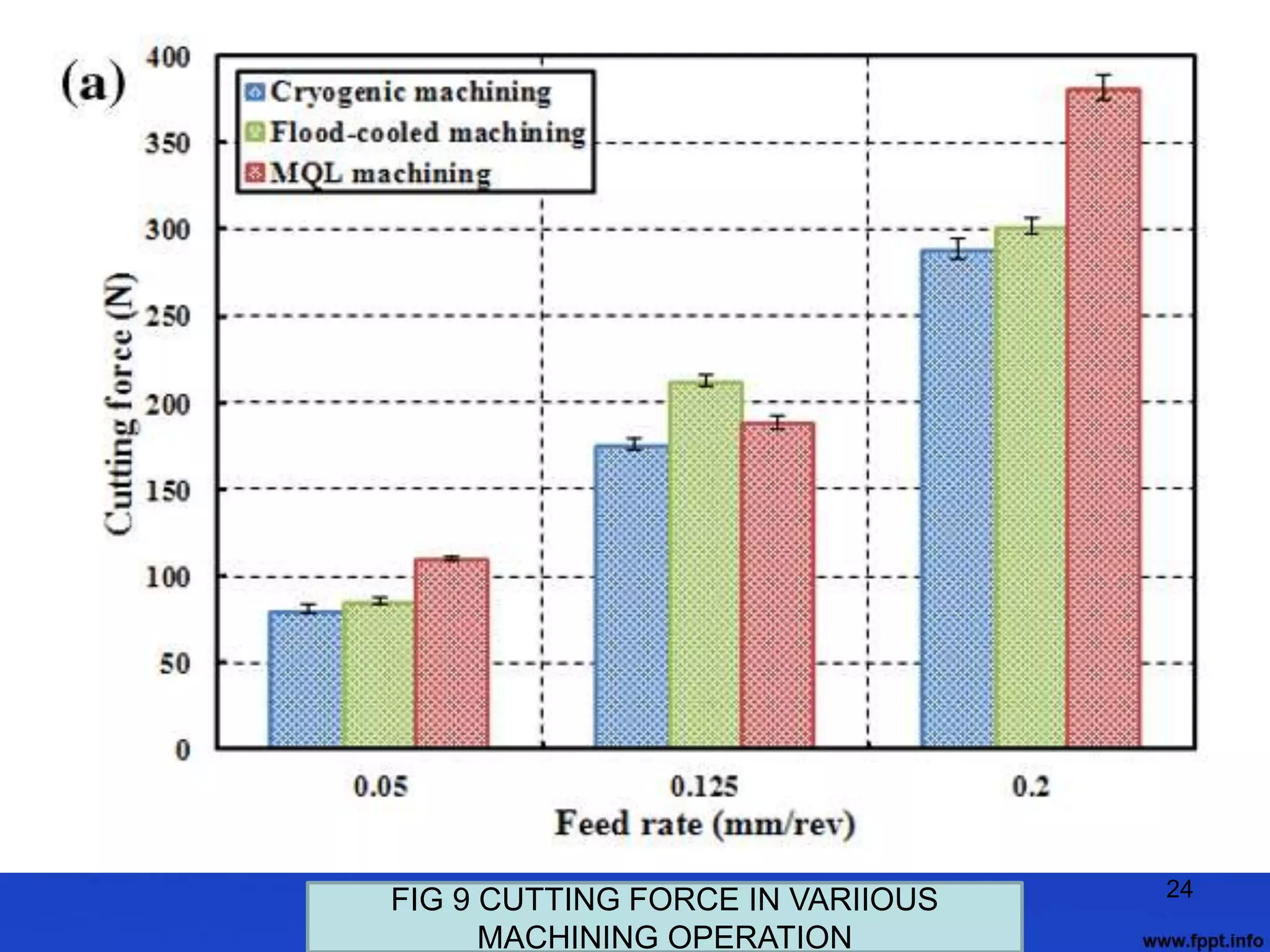

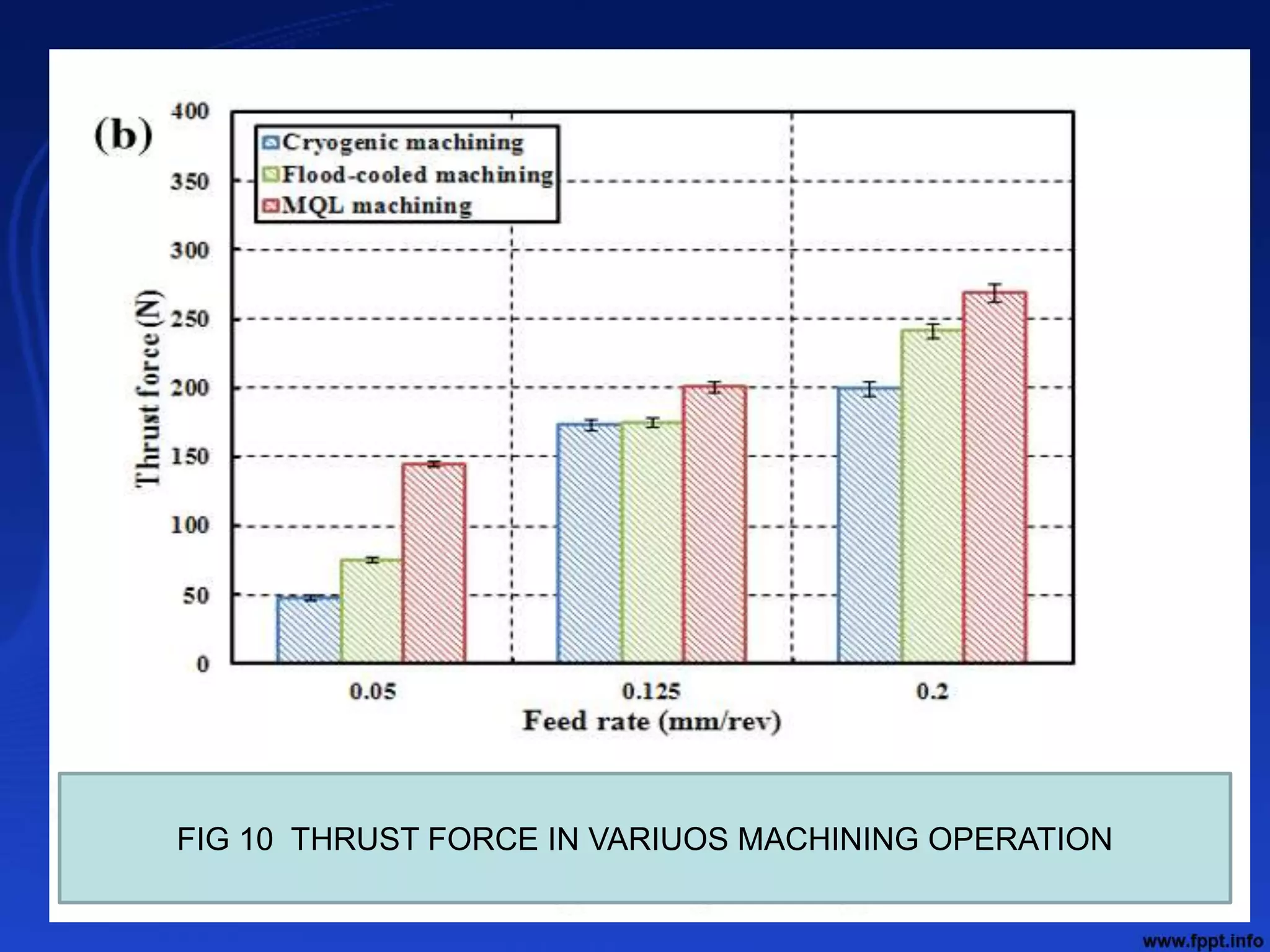

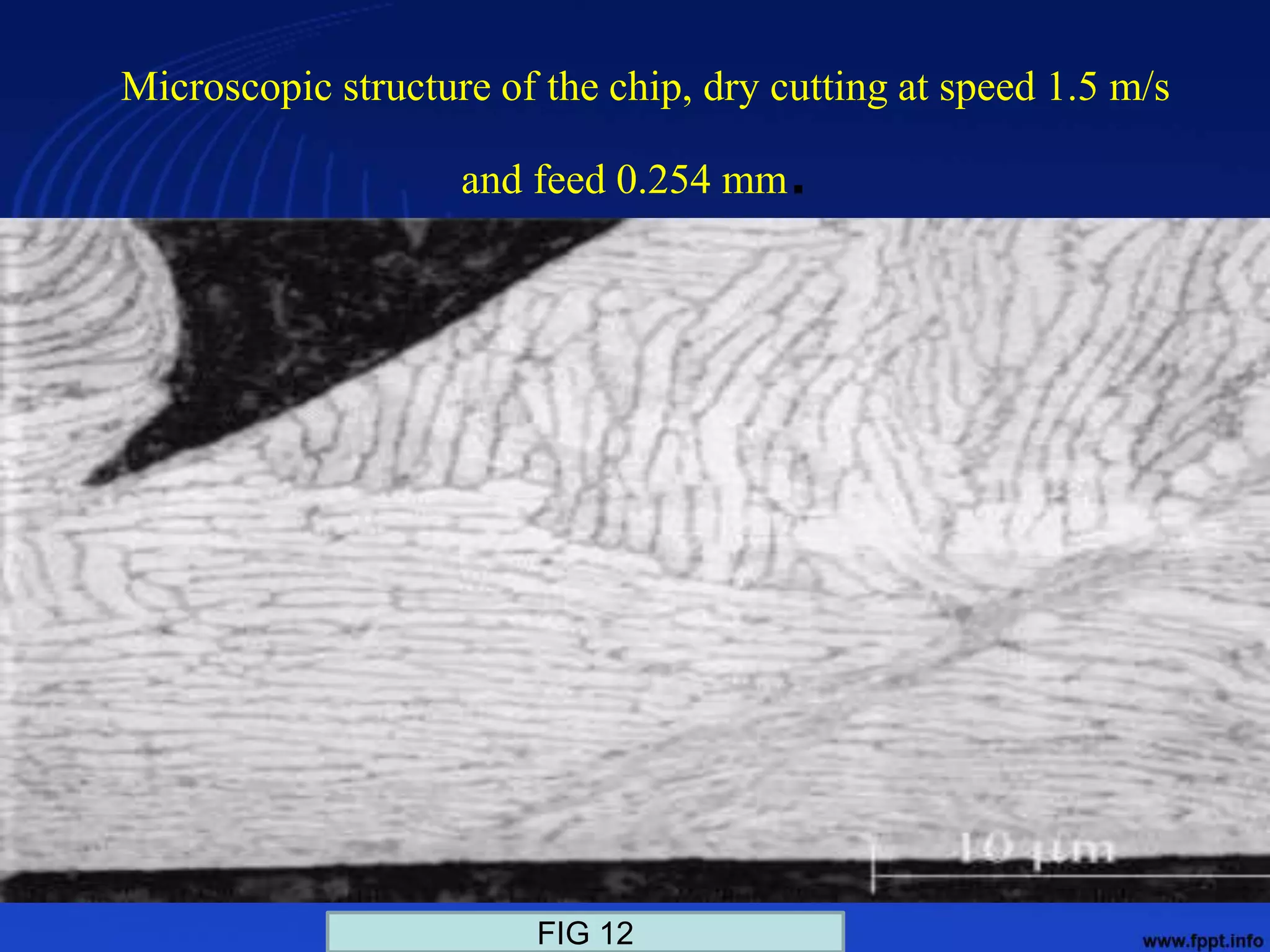

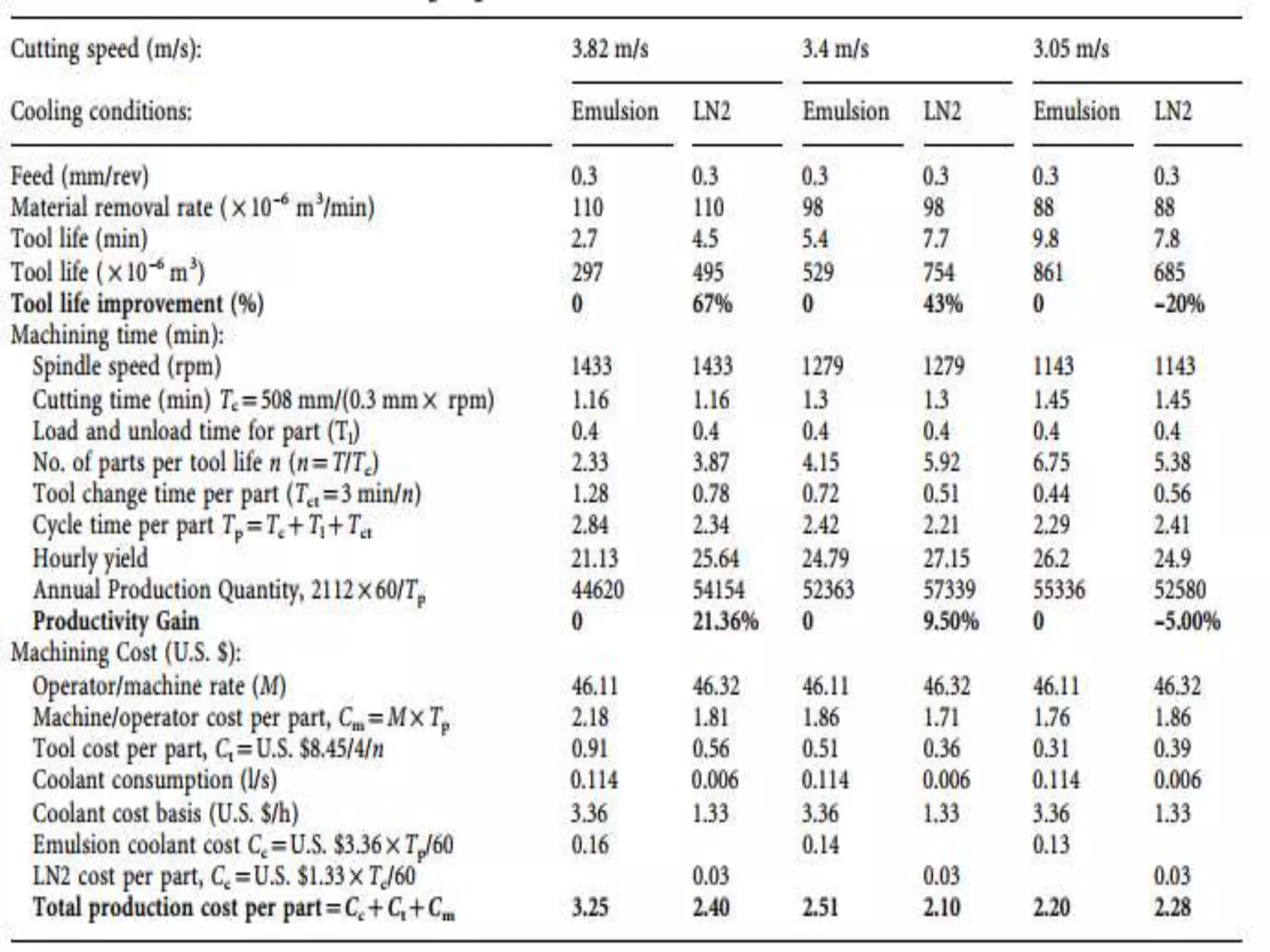

Cryogenic machining utilizes liquid nitrogen (LN2) as a coolant to enhance the machining process, providing benefits such as improved surface integrity, extended tool life, and reduced environmental impact compared to conventional cutting fluids. The document discusses the history, production, and advantages of cryogenic machining, highlighting its application in difficult-to-machine materials and the potential for increased productivity and efficiency in manufacturing. Overall, cryogenic machining is positioned as an eco-friendly, cost-effective alternative that allows for better processing of challenging materials while minimizing health risks.