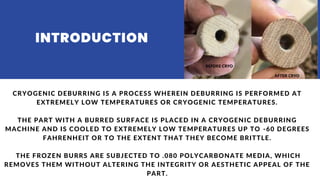

Cryogenic deburring is a specialized process that removes burrs from parts at temperatures as low as -60 degrees Fahrenheit, utilizing polycarbonate media to maintain the integrity and aesthetics of the workpieces. The process is safe, produces no dust or residues, and is effective in preserving the original geometry and surface finish of components. Safety measures such as PPE, training, and ventilation are crucial to ensure a safe working environment when handling cryogenic gases.